Rib strip ejection structure above hot runner

A technology of rubber channels and ribs, which is applied in the field of rib ejection structures, can solve the problems of interfering waterways, ribs withdrawing from the drawing die, and insufficient strength of the ejection structure, so as to avoid the phenomenon of drawing dies and occupy a small space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

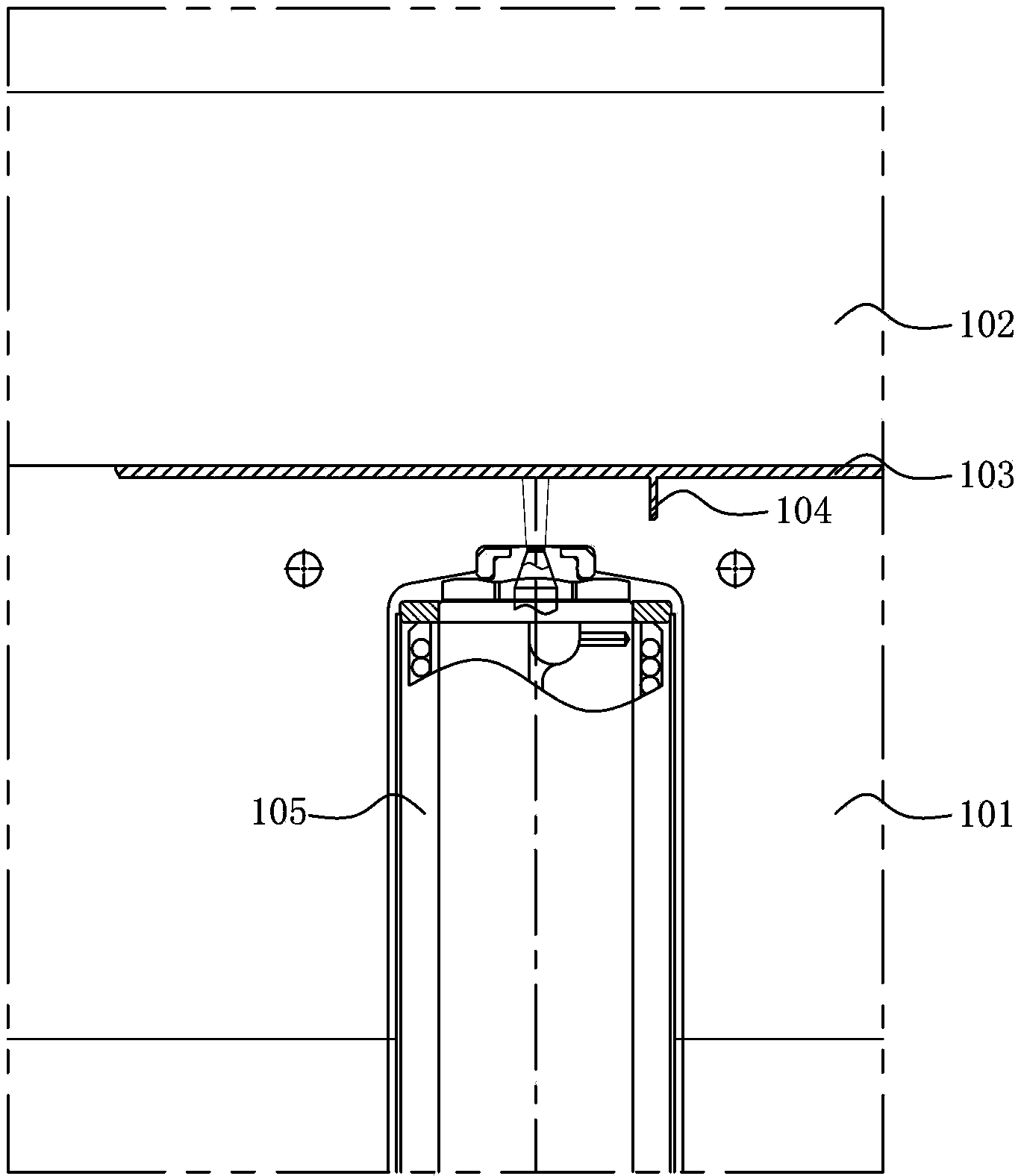

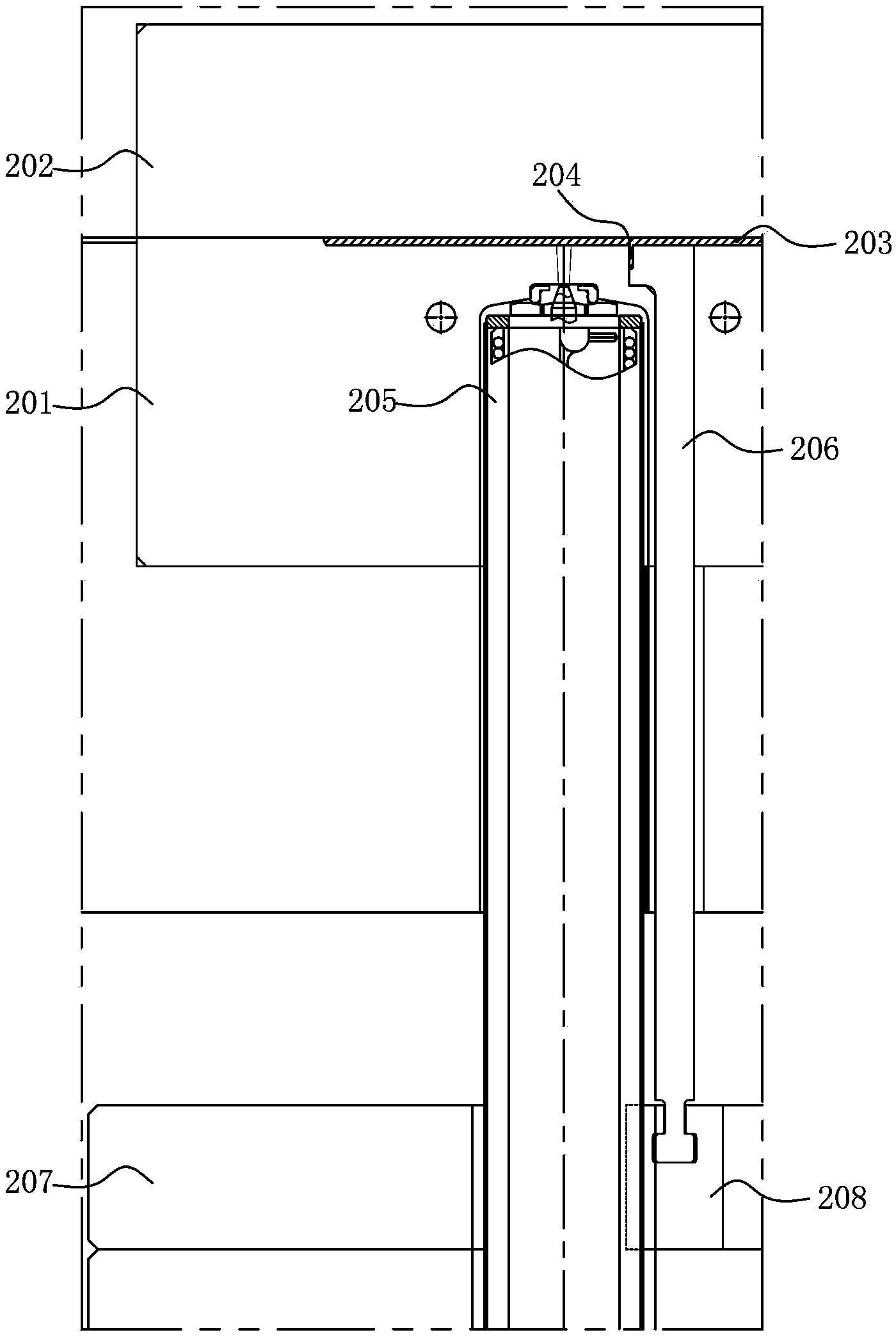

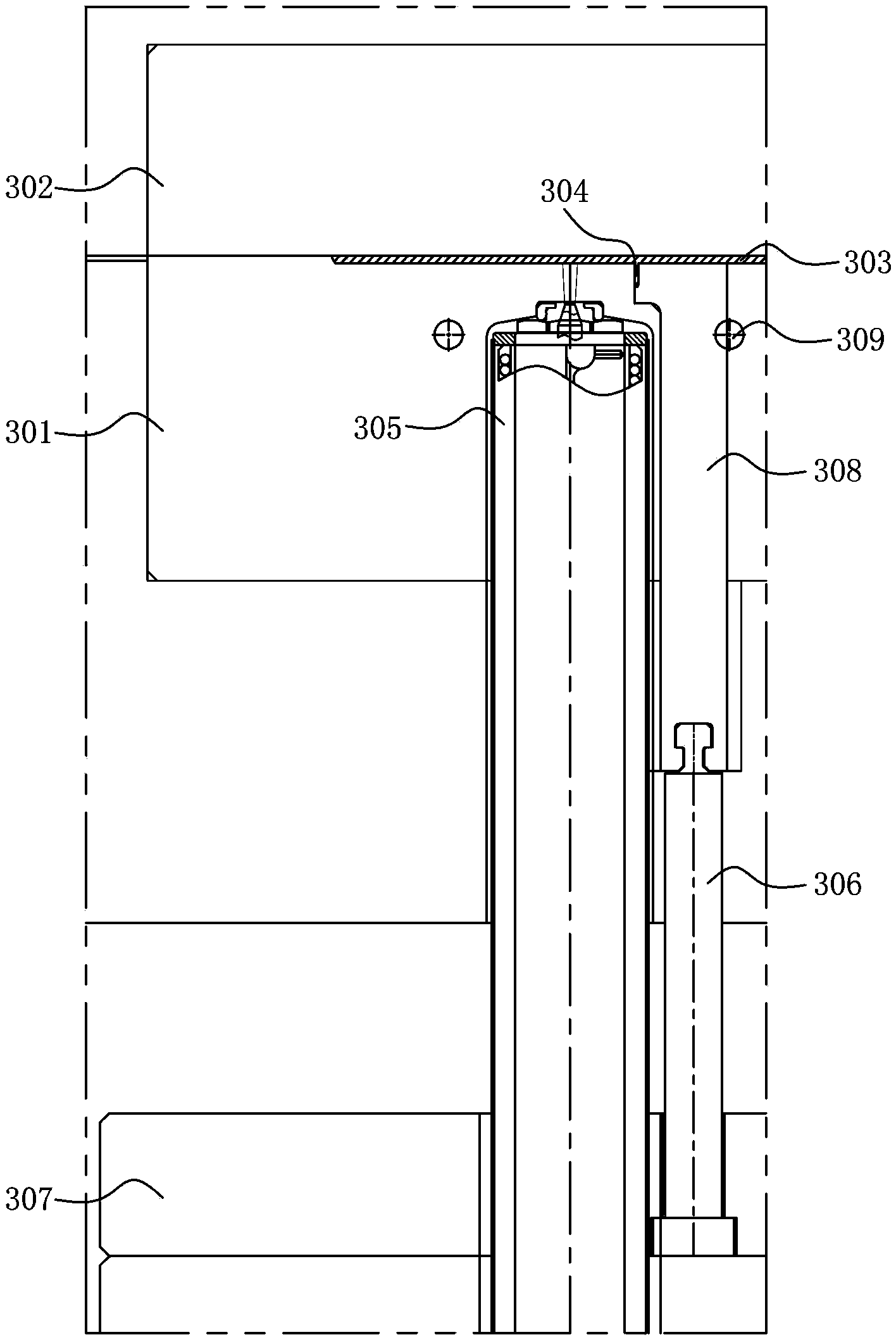

[0018] See Figure 4 , Figure 4 Shown is a schematic structural view of a preferred embodiment of the rib ejection structure above the hot glue lane of the present invention.

[0019] In order to achieve the above purpose, the rib ejection structure above the hot glue lane of the present invention is provided in a mold having an ejector plate 407 and a male mold core 401 and a female mold core 402 of the molded product 403, The male mold core 401 is provided with a hot glue lane 405, the product 403 has a rib 404, and the rib 404 is located above the hot glue lane 405. The ejection structure includes:

[0020] A thimble 406, one end of which is fixed to the ejection plate 407, and the other end of the thimble 406 has a spherical connecting portion 410;

[0021] The oblique pin 408 has one end located above the hot glue channel 405 and has a forming part that cooperates with the male mold core 401 to form the rib 404, and the other end of the oblique pin 408 has a spherical connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com