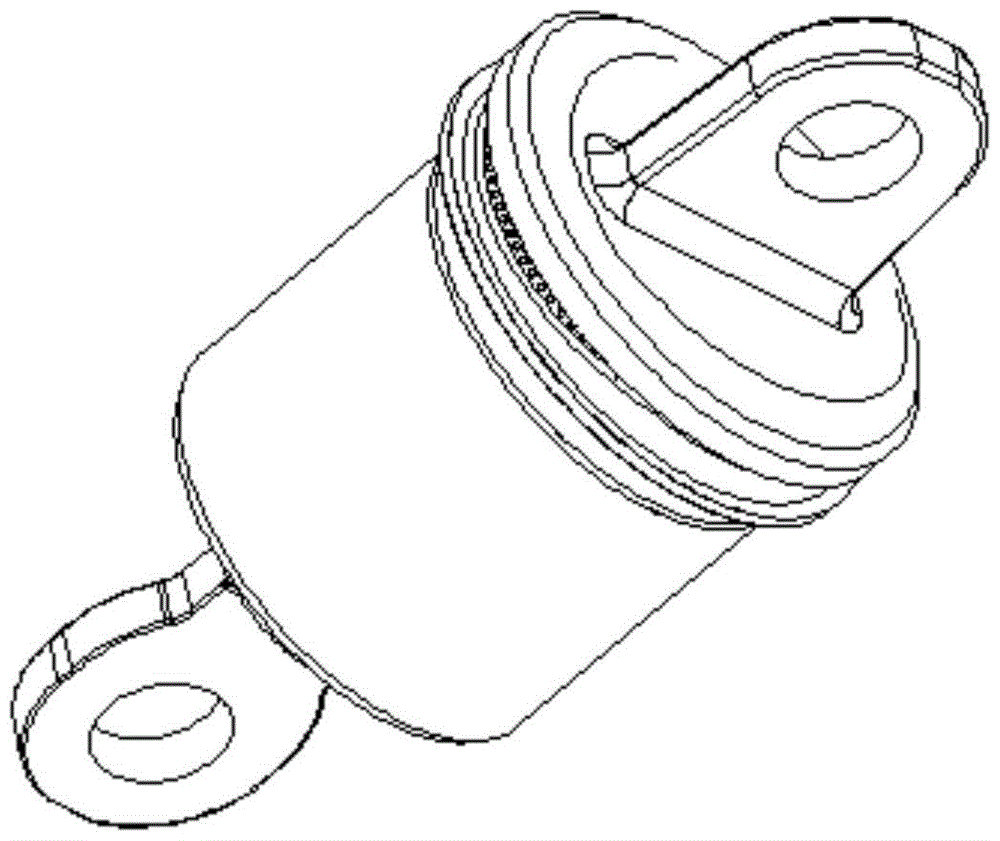

A car rear axle bushing

A rear axle and bushing technology, applied in vehicle components, interconnection systems, springs made of plastic materials, etc., can solve the problems of loss of comfort, impact on comfort, no limit function, etc., to achieve durability and Comfort, improve ride comfort, prevent abnormal noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

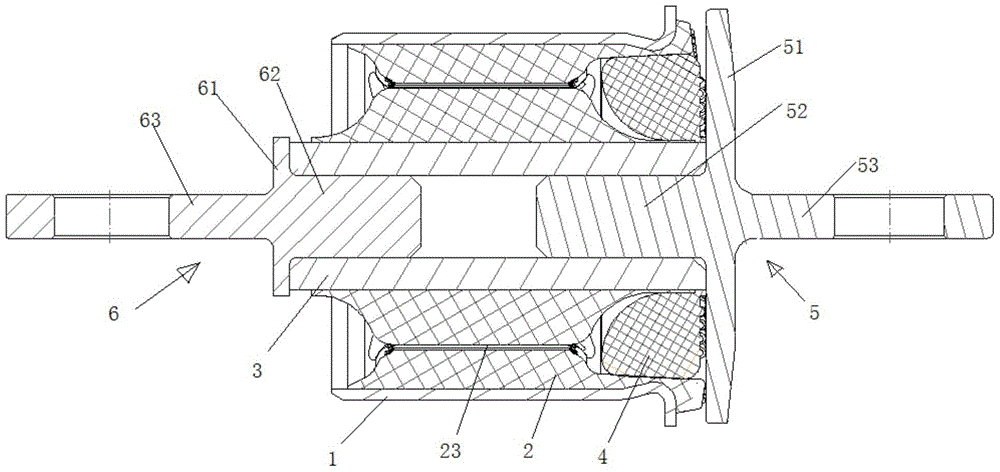

[0027] refer to figure 1 , figure 2 , A car rear axle bushing proposed by the present invention includes: an outer sleeve 1, a rubber body 2, an inner sleeve 3, a washer 4, a first bracket 5 and a second bracket 6.

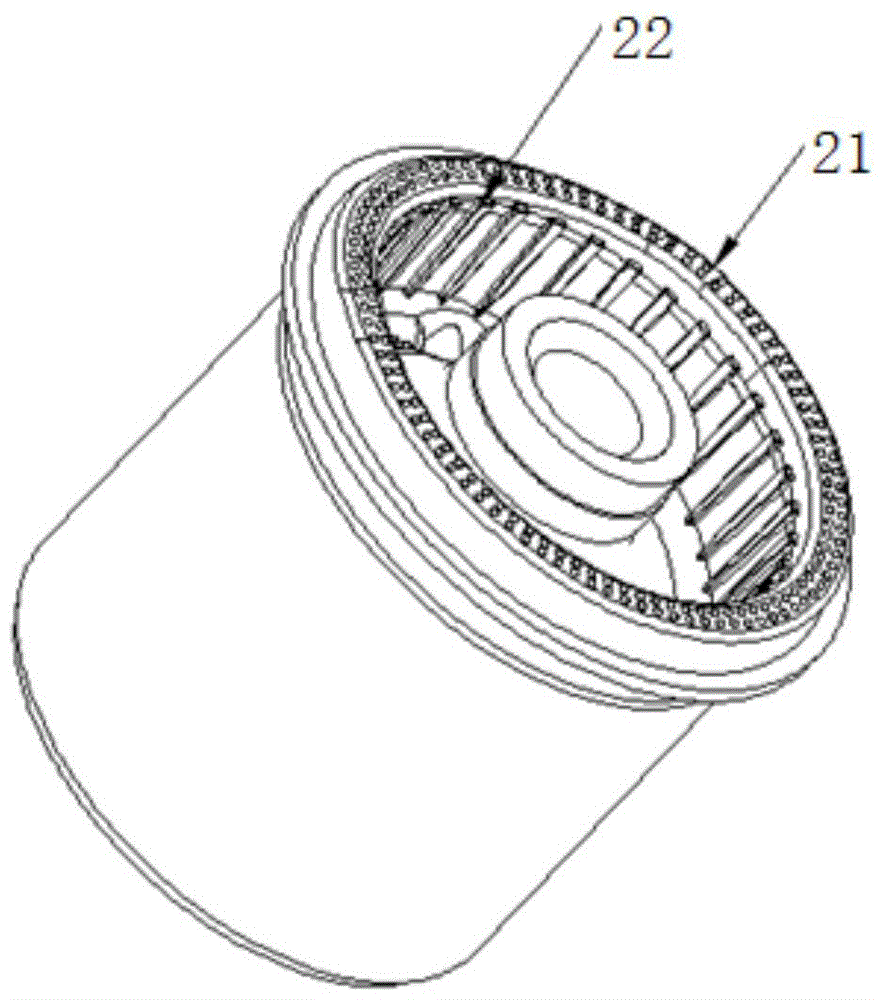

[0028] refer to figure 2 , image 3 , the outer casing 1, the rubber body 2 and the inner casing 3 are installed coaxially from outside to inside and vulcanized to form a glued part.

[0029] refer to image 3 , the first end of the rubber body 2 extends out of the outer casing 1 and is designed as a curved surface of revolution, the circular section of the first end of the rubber body 2 is designed with a first convex spherical surface 21 distributed in the circumferential direction, and the inner wall of the first end of the rubber body 2 is provided with a parallel The bar-shaped tooth protrusion 22 on the central axis. refer to Figure 4 , the rubber body 2 is also symmetrically provided with two limiting holes 23, the limiting holes 23 run through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com