Support for storing and/or moving metal materials, especially metal strips

A metal material, support technology, used in transportation and packaging, external frames, packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

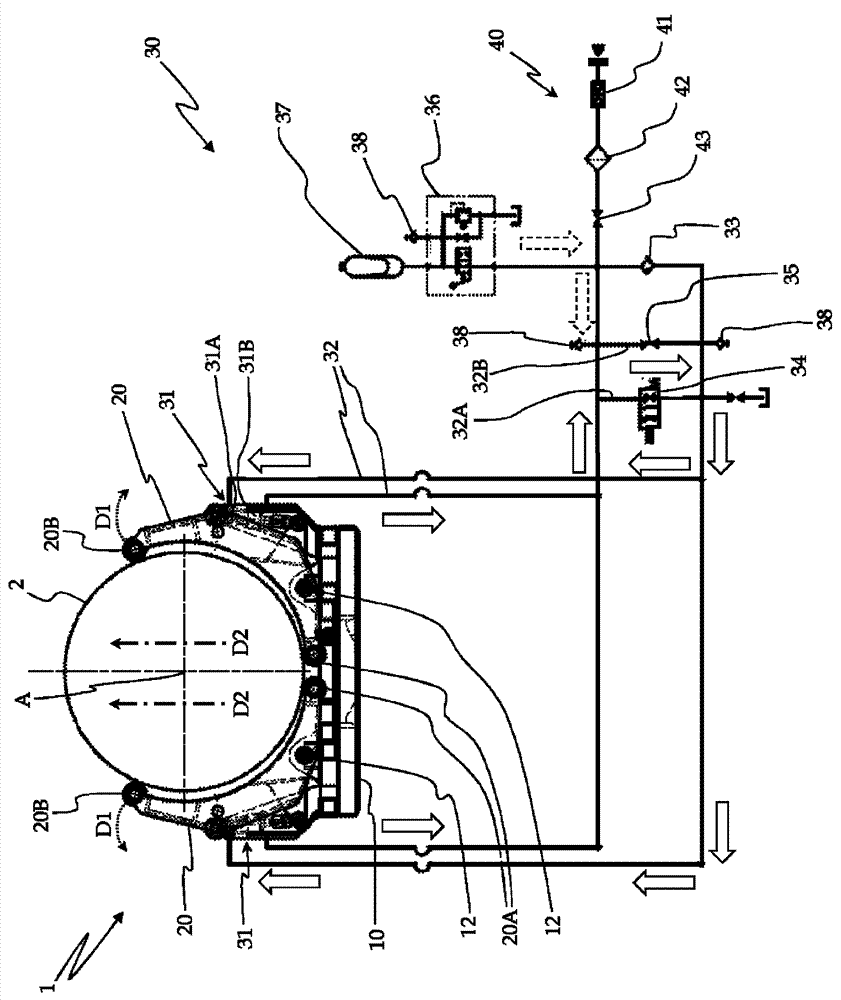

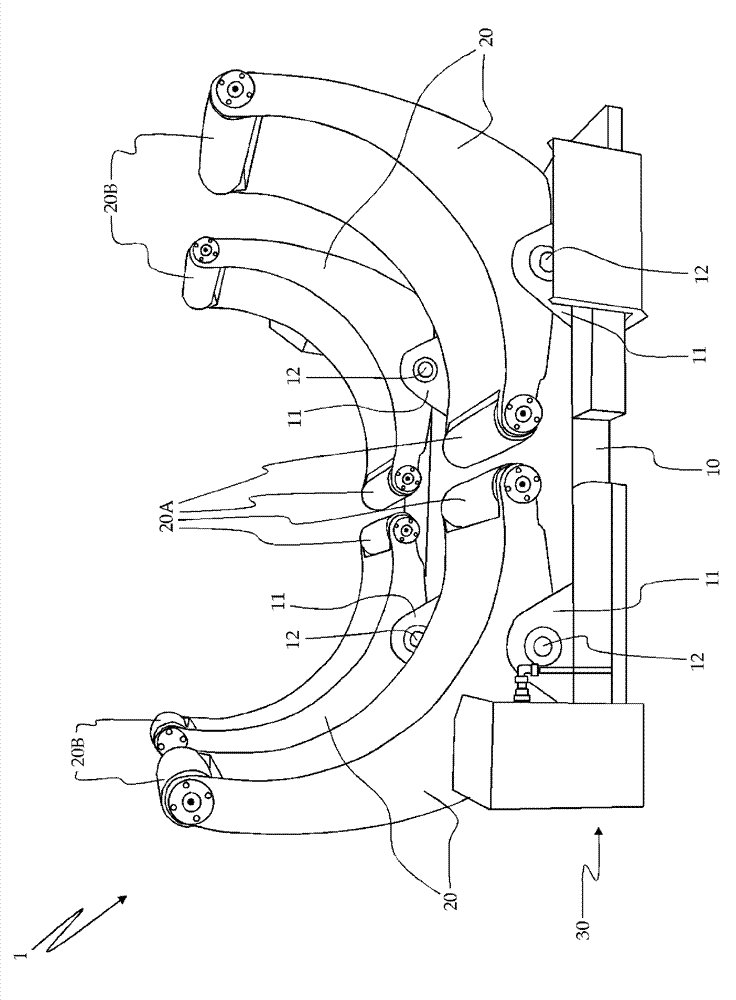

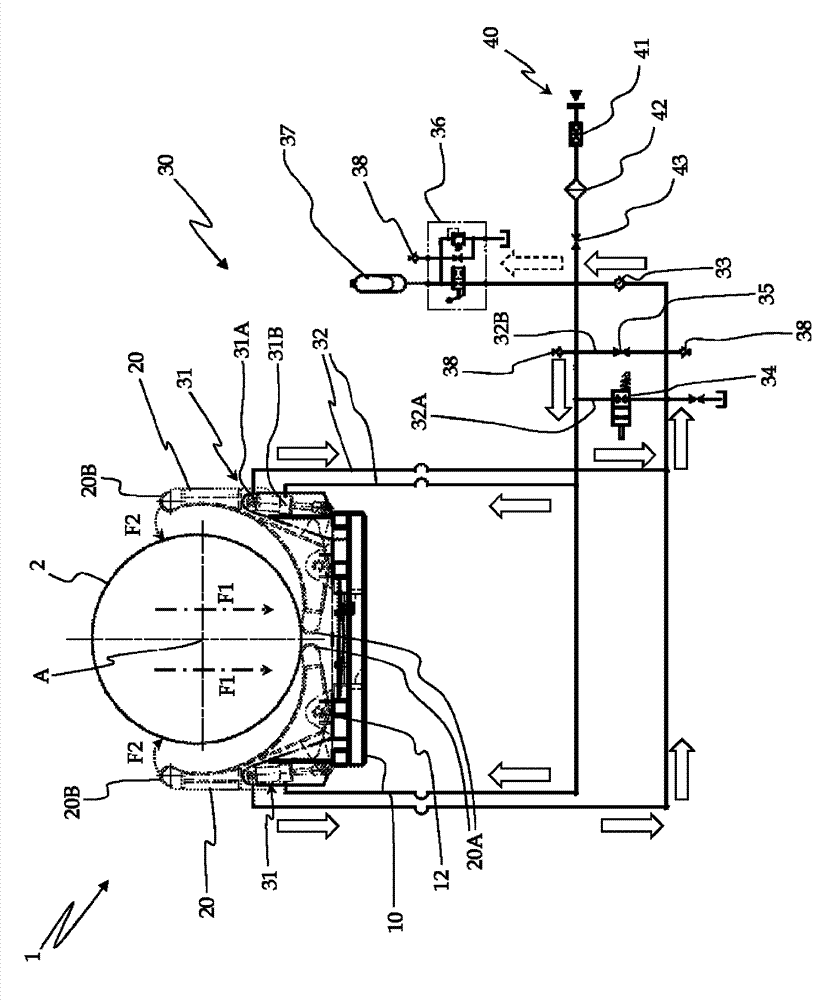

[0031] Referring now to the accompanying drawings, reference numeral 1 generally designates a coil for storing and / or moving metal material according to the present invention (in figure 2 and 3 Indicated with reference numeral 2) supports.

[0032] The support 1 is especially suitable for rolling, especially cold rolling, where the typical objective of a rolling mill is to reduce the thickness of the strip to be rolled, usually a metal strip (e.g. made of steel, copper or their alloys, aluminum or made of its alloy).

[0033] The support 1 comprises a base 10 which can be provided with moving means (not shown in the figures) to allow the movement of the support 1; for example, said moving means may comprise wheels, preferably adapted to turn on suitable tracks to move Said support 1 is used, in particular along a predetermined trajectory, for loading the roll on the unwinding reel and / or for removing the roll from the winding reel.

[0034] The support 1 according to the i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap