Filament hanging clamp of spinning collection machine and filament hanging method of spinning collection machine

A technology of wire clamping and spinning, which is applied to the wire hanging fixture of the spinning take-up machine and the hanging yarn field of the spinning take-up machine, which can solve the problem of time-consuming hanging silk operation, and achieve the effect of short time and variable time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

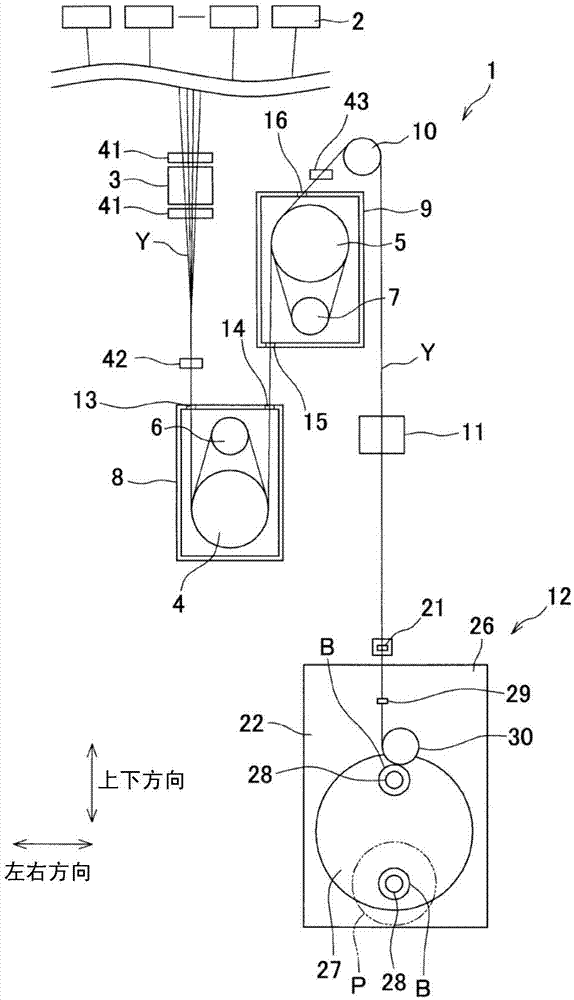

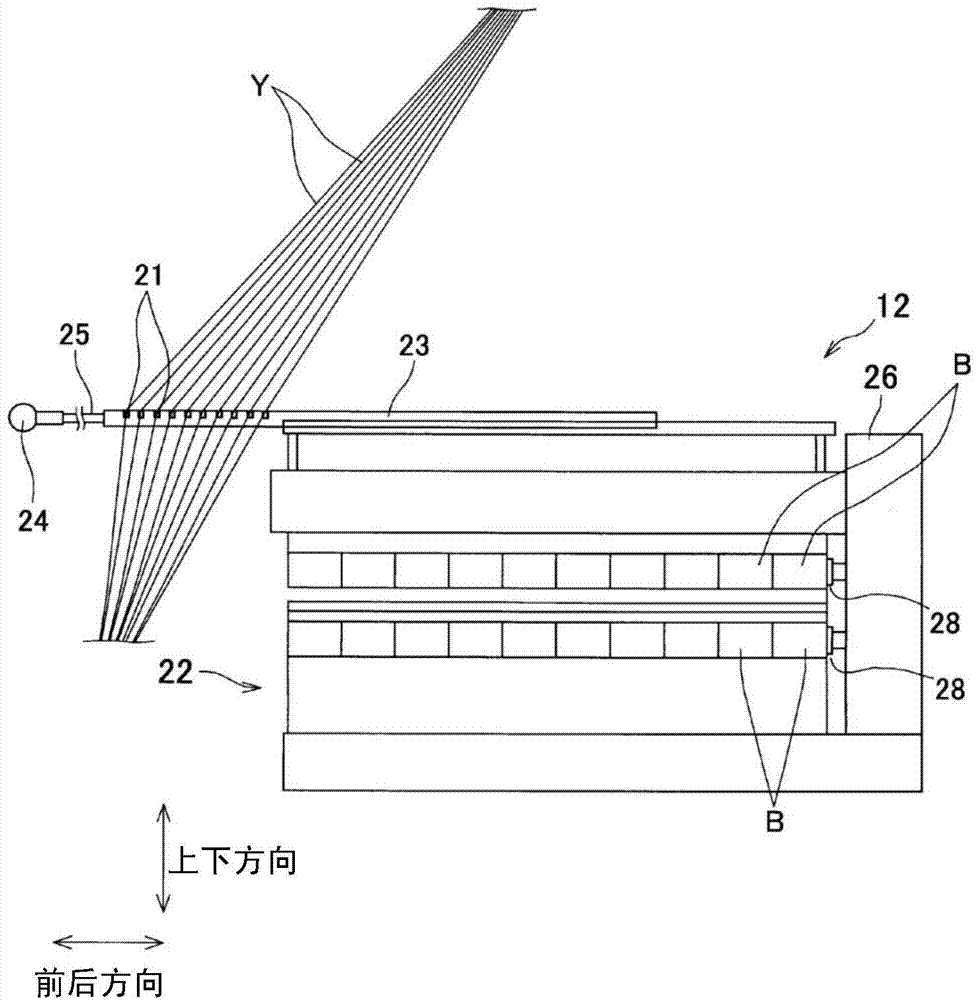

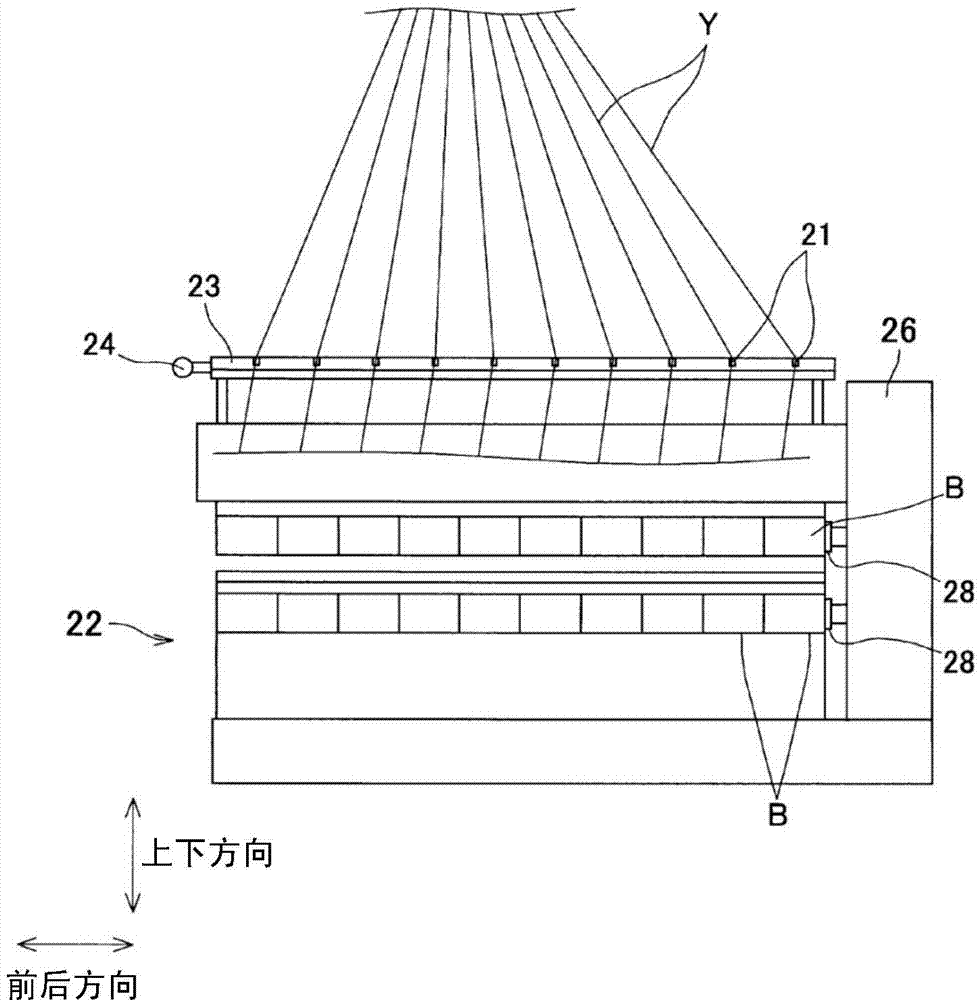

[0055] Embodiments of the present invention will be described below. The yarn hanging jig of the spinning recovery machine according to the present invention is a device for hanging a plurality of yarns spun from a spinning device on a yarn guide or the like of the spinning recovery machine. First, the spinning take-up machine will be described. In addition, in the following description, each direction shown in the drawings will be described as an up-down direction, a left-right direction, and the like. figure 1 It is a front view showing the structure of a spinning take-up machine. Such as figure 1 As shown, the spinning take-up machine 1 draws and winds a plurality of yarns Y spun from a spinning device 2 to form a plurality of packages P, respectively. Spinning collection machine 1 is equipped with: yarn processing device 3, godet rollers 4, 5, separation rollers 6, 7, incubator 8, 9, guide roller 10, interlacing device 11, yarn winding device 12, yarn guide 41 ~43 etc....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com