A kind of coffee charcoal double-layer warm tweed

A coffee charcoal and tweed technology, applied in textiles, fabrics, multi-strand fabrics, etc., can solve problems such as easy mutual influence performance, and achieve the effects of good wear resistance, firm texture and good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

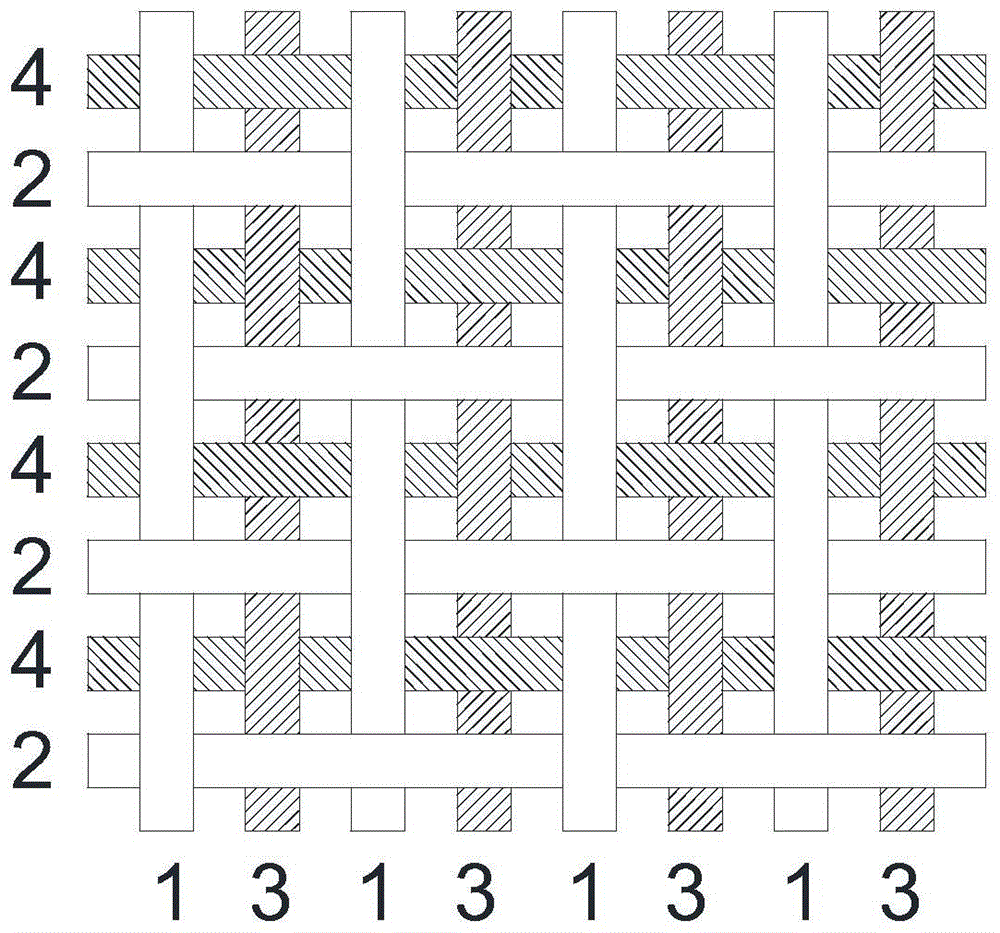

[0026] The yarn count of surface warp 1 is 88S / 2, the density of surface warp 1 is 502 threads / 10cm, the yarn count of surface weft 2 is 88S / 2, and the density of surface weft 2 is 468 threads / 10cm. The yarn count of inner warp 3 is 88S / 2, the density of inner warp 3 is 502 threads / 10cm, the yarn count of inner weft 4 is 88S / 2, and the density of inner weft 4 is 468 threads / 10cm. The fabric has a width of 150cm and a weight of 228g / m 2 .

Embodiment 2

[0028] The yarn count of surface warp 1 is 90S / 2, the density of surface warp 1 is 504 threads / 10cm, the yarn count of surface weft 2 is 90S / 2, and the density of surface weft 2 is 470 threads / 10cm. The yarn count of inner warp 3 is 90S / 2, the density of inner warp 3 is 504 threads / 10cm, the yarn count of inner weft 4 is 90S / 2, and the density of inner weft 4 is 470 threads / 10cm. The fabric has a width of 152cm and a weight of 230g / m 2 .

Embodiment 3

[0030] The yarn count of surface warp 1 is 92S / 2, the density of surface warp 1 is 506 threads / 10cm, the yarn count of surface weft 2 is 92S / 2, and the density of surface weft 2 is 472 threads / 10cm. The yarn count of inner warp 3 is 92S / 2, the density of inner warp 3 is 506 threads / 10cm, the yarn count of inner weft 4 is 92S / 2, and the density of inner weft 4 is 472 threads / 10cm. The fabric has a width of 154cm and a weight of 232g / m 2 .

[0031] Among them, the wool is Merino wool. The quality of Merino wool is uniform, the ends are flat, there is no hair pith in the fiber, the cortex layer and the subcortex layer are arranged side by side, and the color is white after washing. It has a silver or pearl-like elegant luster. Merino wool has excellent spinning performance, high spinnable count, soft and elastic feel, suitable for making excellent worsted fabrics, and it also has good shrinkage. It is also an excellent raw material for full and tight woolen fabrics. The fabric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com