Carbon fiber sheet and preparation process of carbon fiber sheet

A technology of carbon fiber sheet and carbon fiber, which is applied in the direction of lamination, layered products, synthetic resin layered products, etc., can solve the problems of low performance, achieve good wear resistance, high tensile strength, and ensure stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

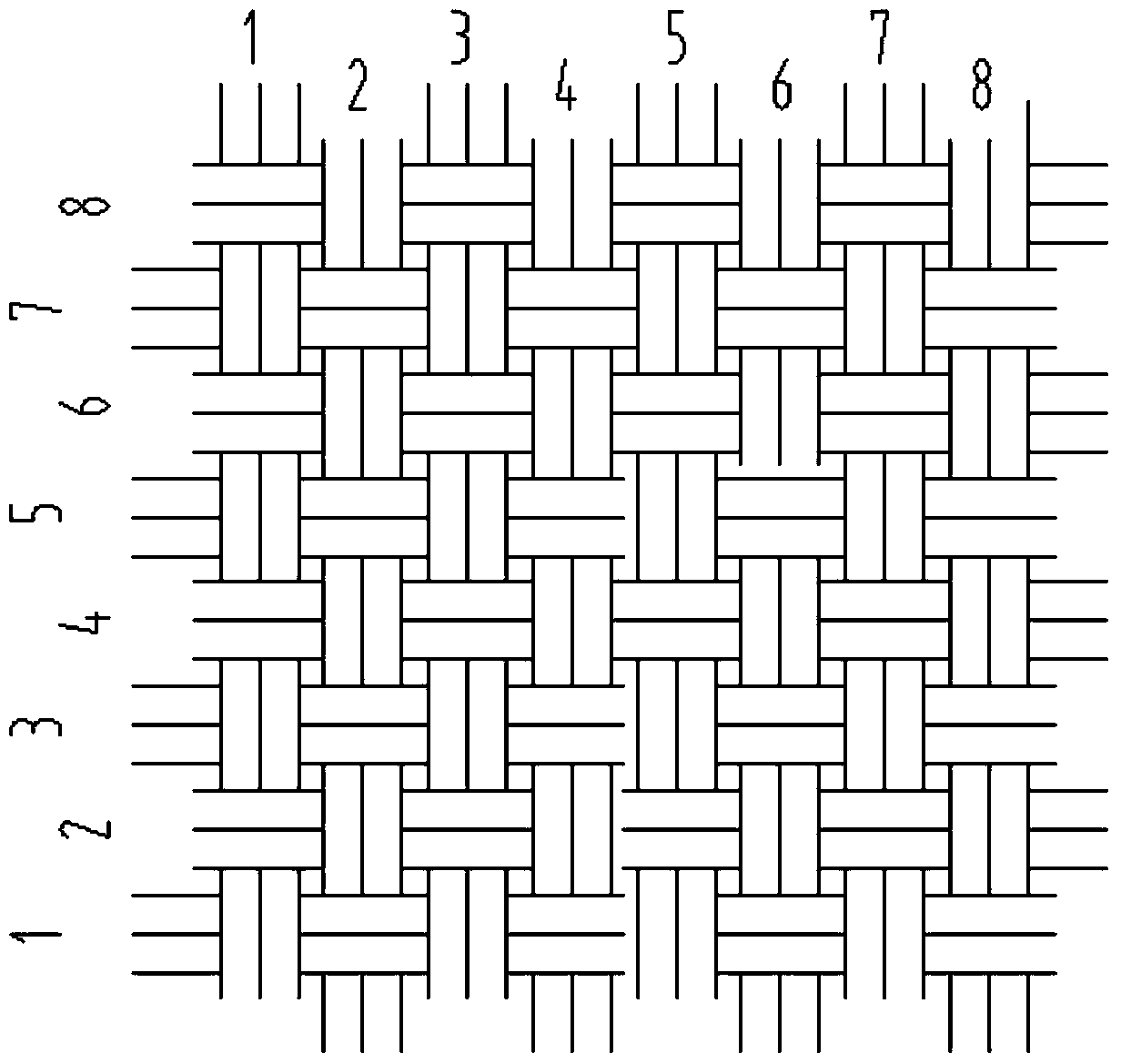

[0034] Such as Figure 6 Shown is a schematic diagram of the structure of the carbon fiber sheet of the present invention. The structure of the carbon fiber sheet of the present invention adopts a multilayer structure of longitudinally and transversely interwoven carbon fiber cloth 1 and bidirectionally interwoven carbon fiber filament layers 2 .

[0035] Such as figure 1 As shown, carbon fiber cloth woven by longitudinal carbon fiber and transverse carbon fiber is used as the base material, and the width and number of layers of carbon fiber cloth required for the plate can be determined according to product requirements.

[0036] Such as figure 2 The carbon fiber unidirectional cloth is shown, and the carbon fiber unidirectional cloth has carbon fibers in both longitudinal and transverse directions, but there are a large number of untwisted rovings in one direction (usually the longitudinal direction), and only a small amount of spun yarn in the other direction, which acts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com