Processing technique of water-proof wear-resisting suit pant fabric

A processing technology, waterproof technology, applied in the direction of adhesive additives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problems affecting social and business negotiations, waterproof research, embarrassment, etc., to achieve the appearance The same effect, good air permeability, good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will now be further described.

[0024] A processing technology for waterproof wear-resistant trousers fabric, comprising the following steps:

[0025] (1), prepare surface layer fabric, carry out proportioning with organic cotton fiber and tencel fiber by mass ratio 3:1, make gray yarn by drawing frame, roving, spun yarn winding, adopt plain weave weaving on rapier loom, go up The width of the machine is 178cm, the warp density on the machine is 245 pieces / 10cm, and the weft density is 226 pieces / 10cm;

[0026] (2), prepare the inner layer fabric, mix bamboo fiber and nano-silver particles, make gray yarn by drawing, roving, and spun yarn winding, adopt plain weave on the rapier loom, the width of the upper machine is 178cm, and the upper machine The warp density is 245 threads / 10cm, and the weft density is 226 threads / 10cm;

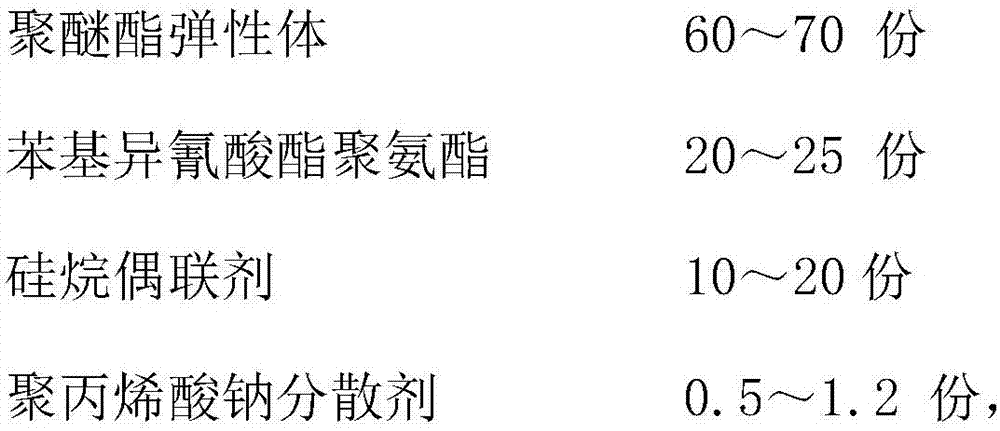

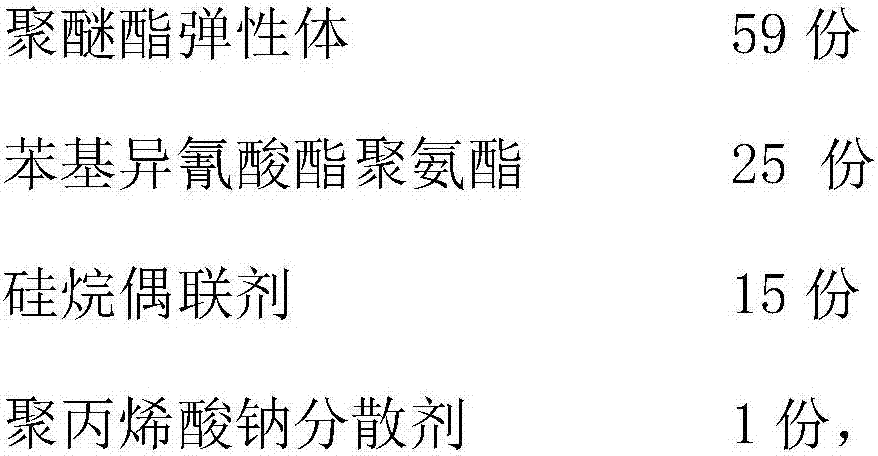

[0027] (3), hot-melt adhesive is coated on the inner surface of the surface fabric, and the components and parts by weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com