Automobile exhaust system hot end support

A technology of automobile exhaust system and hot end, which is applied in the direction of exhaust device, muffler device, engine components, etc. It can solve the problems of installation hole position limitation, reduce the vibration fatigue life of parts, reduce the thermal fatigue life, etc., and achieve the reduction of installation prestress , improve fatigue life, and facilitate installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

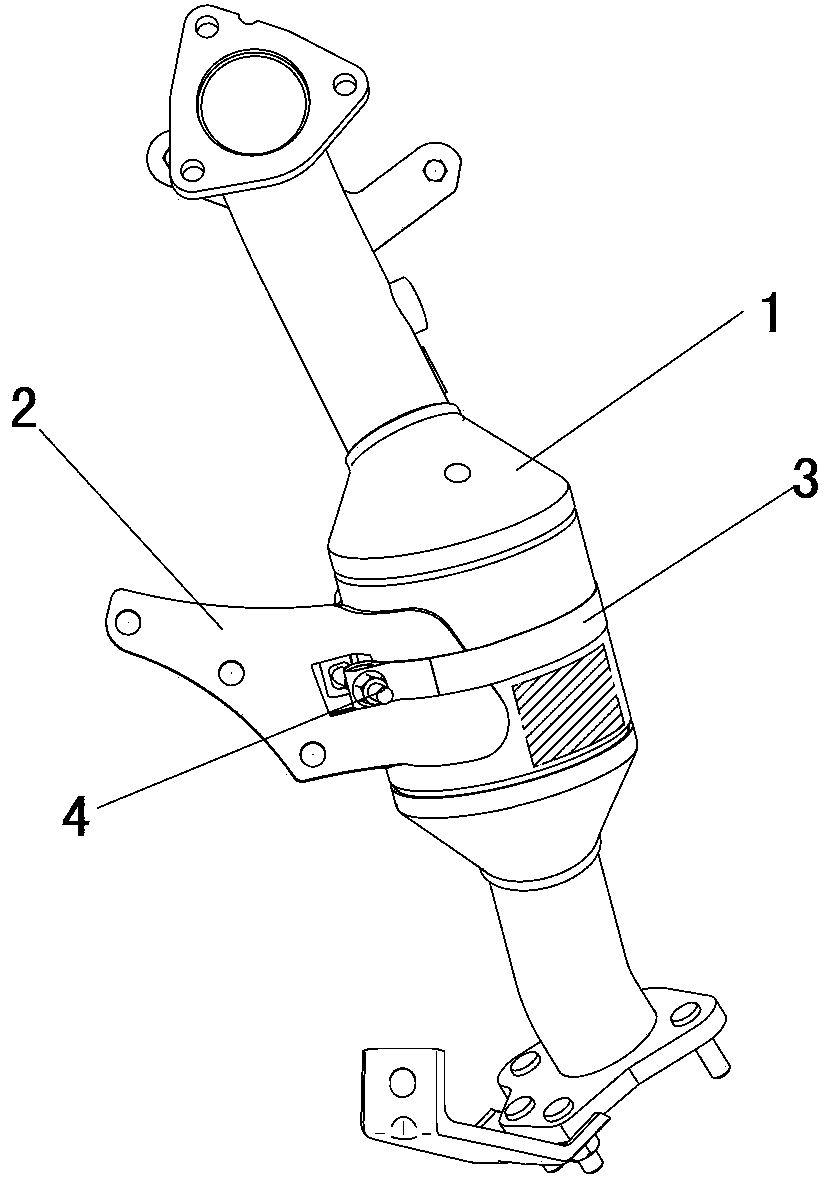

[0014] see figure 1 , figure 2 , the automobile exhaust system hot end bracket of the present invention is used to connect with the three-way catalytic converter housing 1, and includes a bracket body 2, a band 3 and a fastening bolt 4, and the band 3 surrounds the three-way catalytic converter housing 1 and the The fastening bolts 4 are connected to form a clamp, and the fastening bolts 4 pass through the bracket body 2 and are connected to both ends of the band, so as to fix the bracket body on the three-way catalytic converter housing.

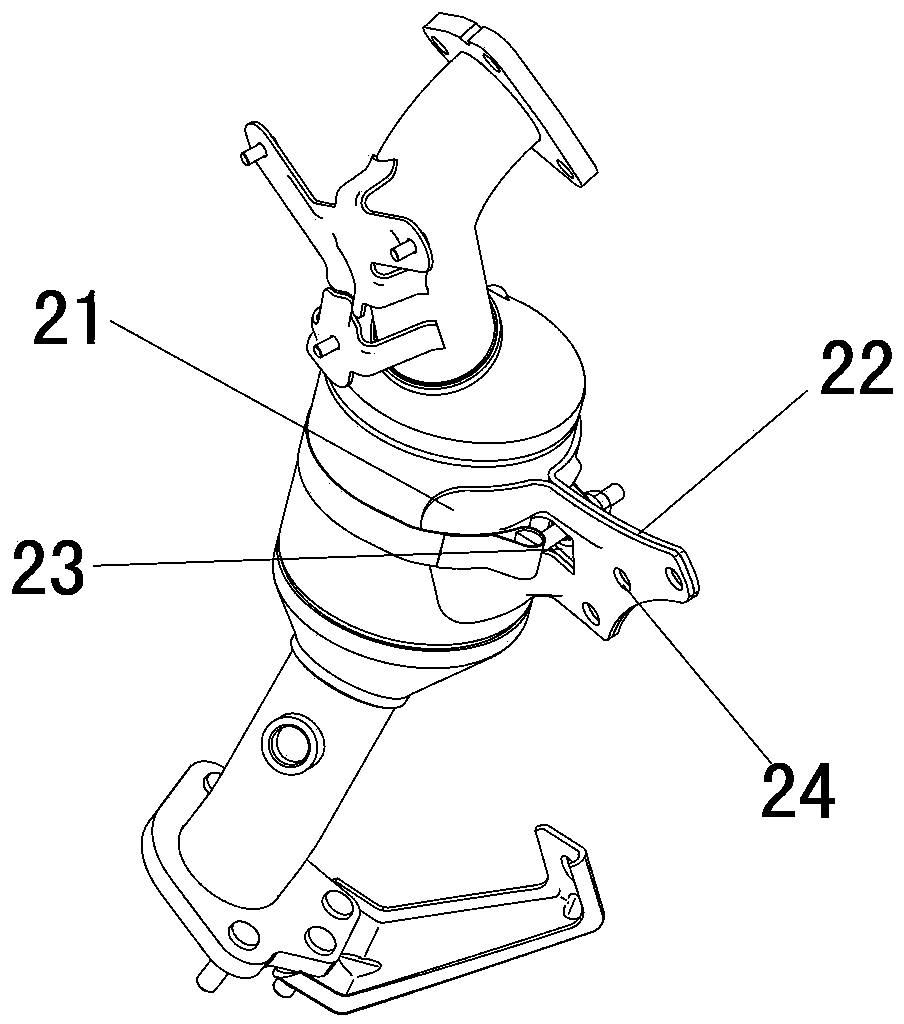

[0015] The bracket body 2 of the present invention includes an arc-shaped connecting surface 21 and an empennage 22, and a perforation 23 is provided at the part of the empennage close to the arc-shaped connecting surface, and the arc-shaped connecting surface of the bracket body is attached to the three-way catalytic converter housing , the fastening bolt is connected to the two ends of the band through the through hole.

[0016] The em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com