Reusable liquid coupling fusible plug

A fluid coupling and fusible plug technology, applied in clutches, clutches, fluid clutches, etc., can solve the problems of loss of safety protection, inconvenient maintenance, and low operability of fluid couplings. , to achieve the effect of improving operability, easy maintenance and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

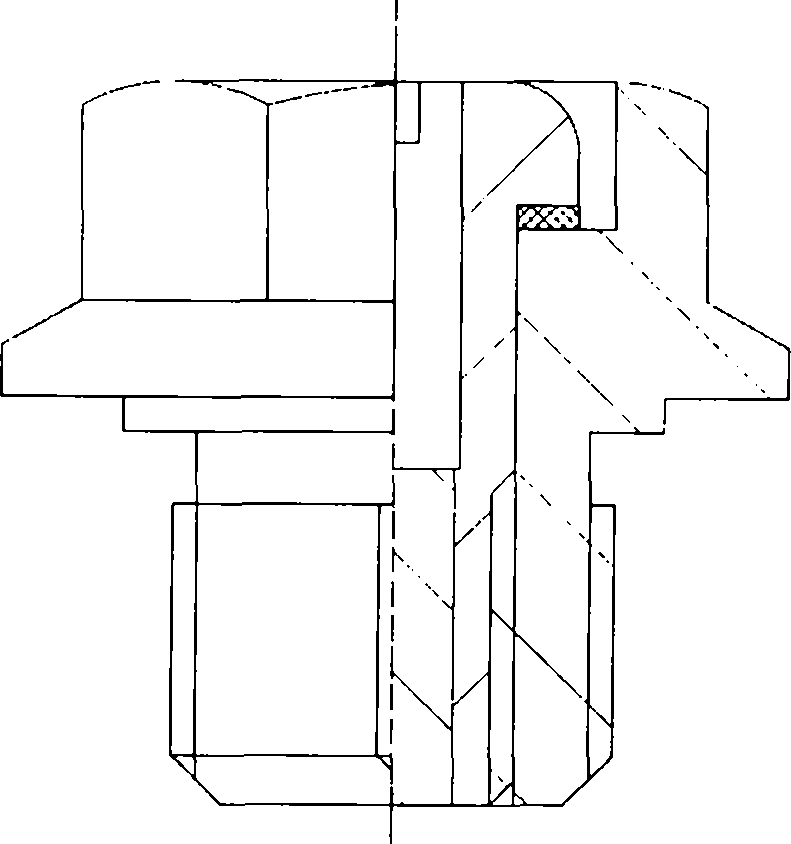

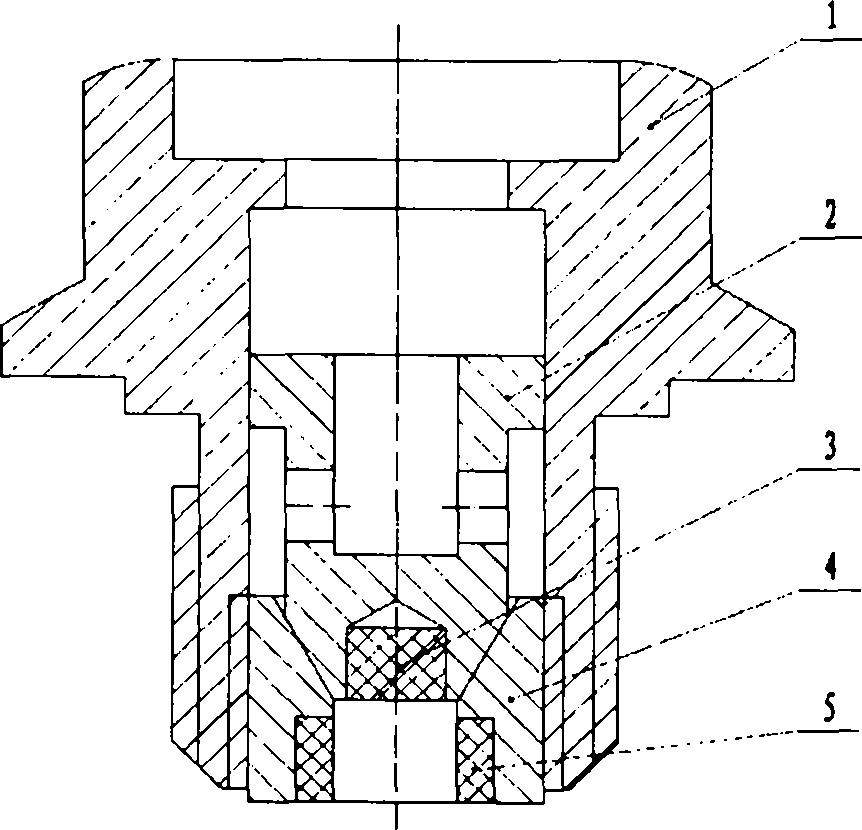

[0010] Such as figure 2 As shown, the reusable fluid coupling fusible plug is composed of fusible plug seat body 1, drain valve 2, ferromagnetic body I 3, valve seat 4, ferromagnetic body II 5; fusible plug seat body 1 is preferably used It has certain strength and is made of non-ferromagnetic materials such as stainless steel and copper. The head has a polygonal outer contour (regular hexagon, regular quadrilateral), so that it is convenient to screw the fusible plug to install or remove the fusible plug. The outside of the bottom is outer The thread is used for installing on the housing of the fluid coupling; the upper middle part of the seat body 1 is provided with a leakage through hole, the middle part is a circular hole, and the lower part is an internal thread.

[0011] The drain valve 2 is preferably made of non-ferromagnetic materials with certain strength and made of stainless steel, copper, etc., and is installed in the central circular hole of the fusible plug seat b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com