Rice tray placing and seeding integrated machine

The technology of an all-in-one machine and a swinging machine is applied in the field of agricultural machinery, which can solve the problems of wasting manpower, low work efficiency, and high local moisture, and achieve the effects of convenient transportation, improved work efficiency, and reduced labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

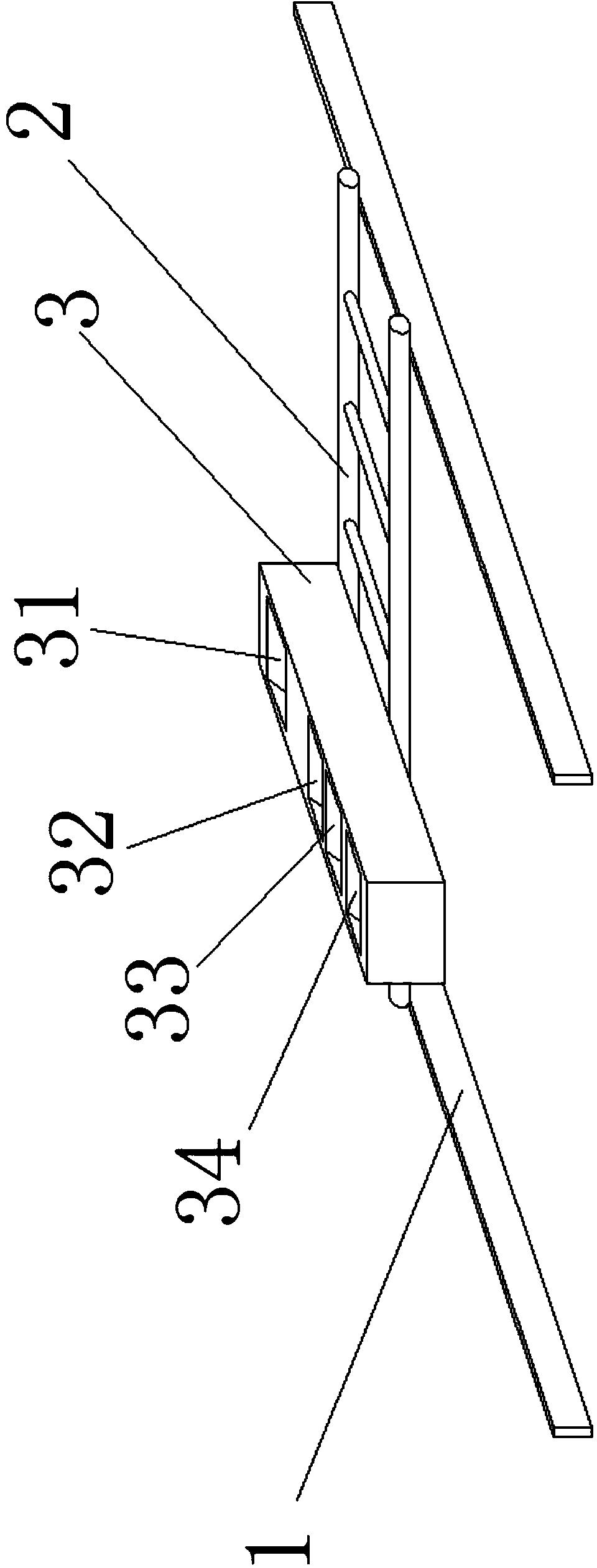

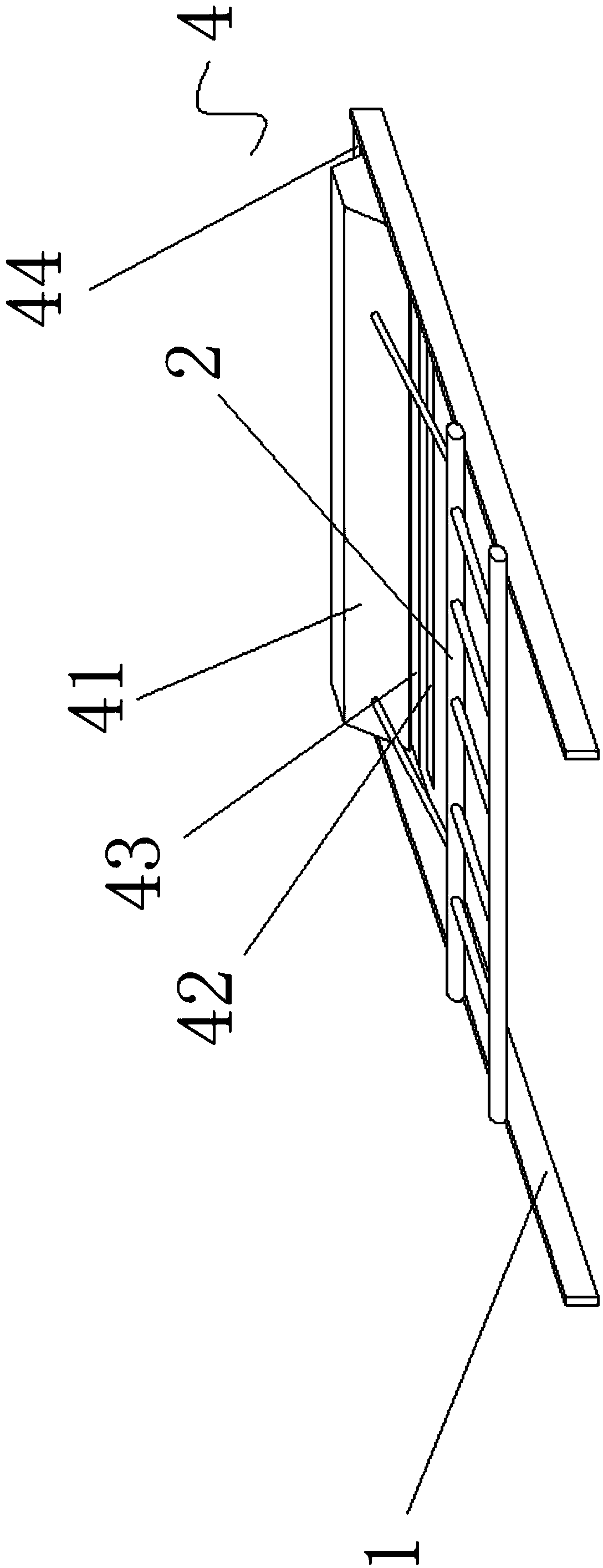

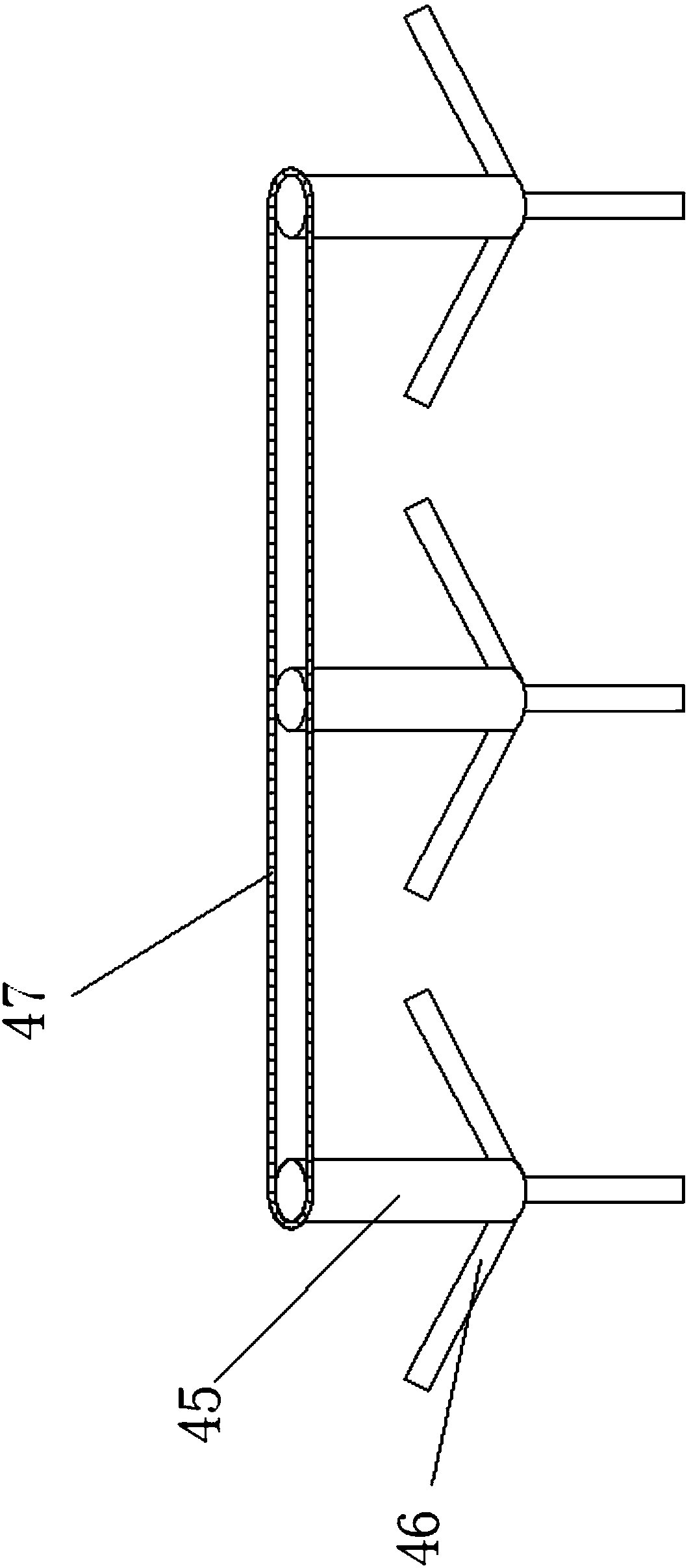

[0032] see figure 1 and Figure 5 , the present invention relates to an all-in-one rice swinging and planting machine, comprising a swinging machine 3, a sliding bracket 2 in the left and right directions, and slide rails in the front and rear directions, the slide rails in the front and rear directions include two sub-slide rails 1, The sub-sliding rails are arranged in parallel, the sliding brackets in the left and right direction span the two sub-sliding rails and are arranged on the two sub-sliding rails, the sliding brackets in the left-right direction and the sliding rails in the front-rear direction direction sliding fit, the plate swinging machine is installed on the sliding bracket in the left and right direction, and the plate swinging machine and the sliding bracket in the left and right direction are slidingly fitted in the left and right direction.

[0033] It should be noted that the present invention is based on greenhouse planting, that is to say, in actual us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com