tea rolling machine

A kneading machine and tea technology, which is applied in the field of tea kneading machines, can solve the problems of non-continuous processing, low processing efficiency, and short service life of kneading machines, and achieve the effects of shortening kneading time, low processing efficiency, and high labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

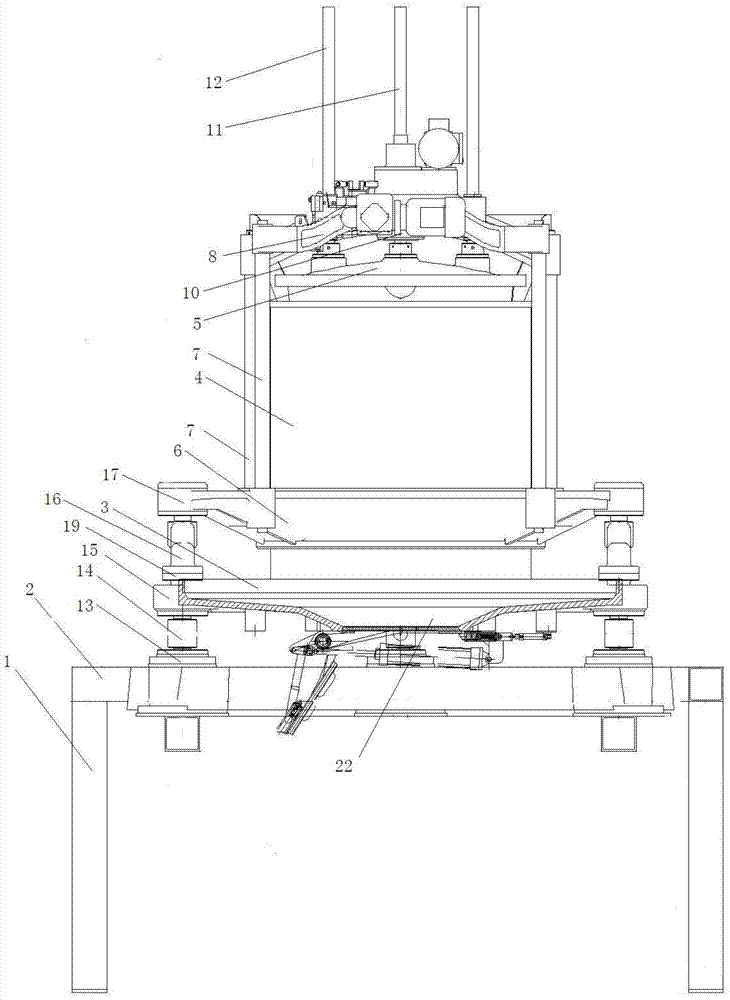

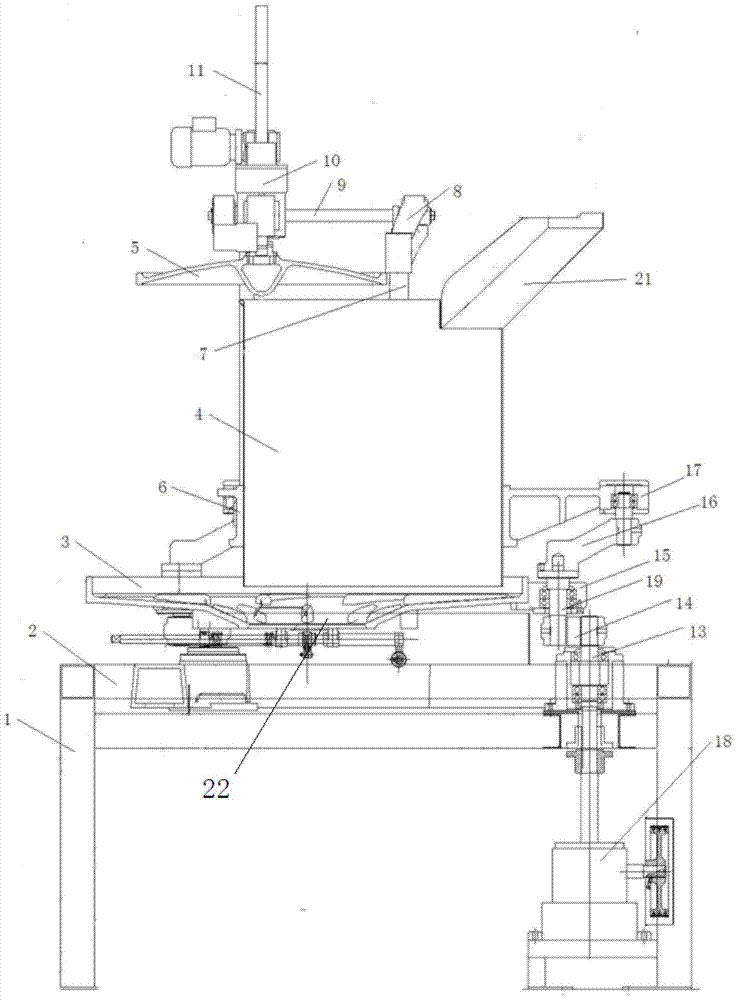

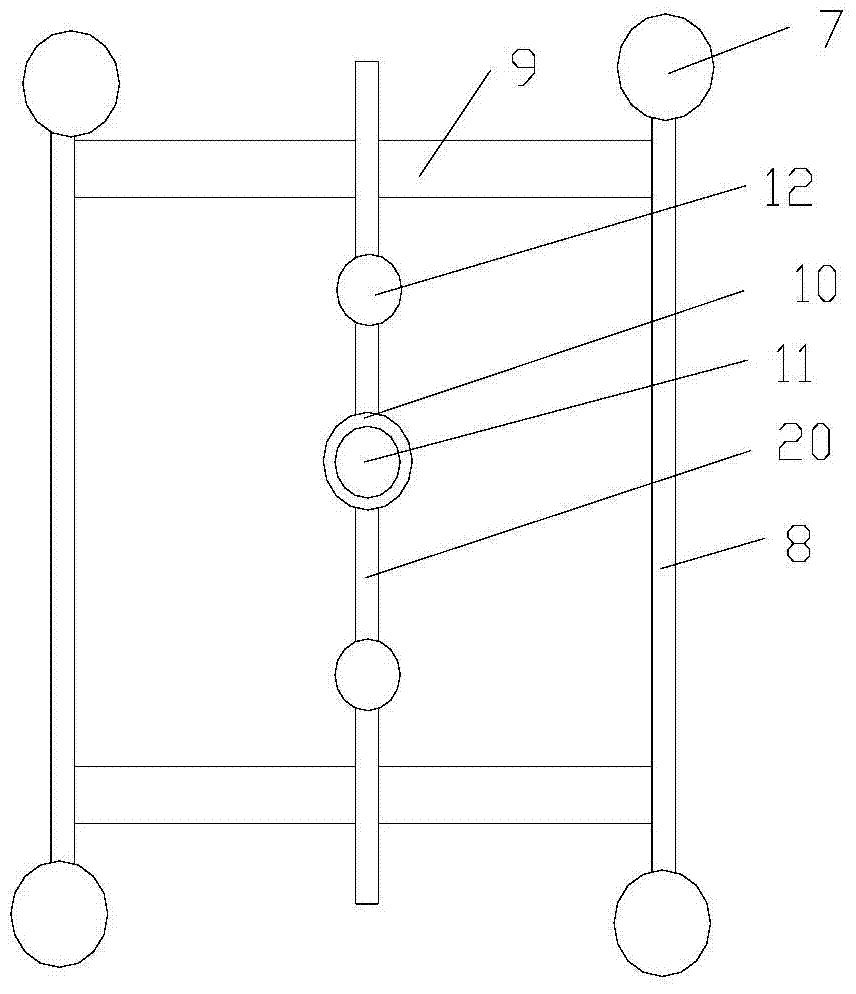

[0019] Example 1, such as figure 1 , figure 2 , image 3 A kind of tea kneading machine shown comprises frame 1, kneading table 2, kneading disc 3, kneading barrel 4 cooperating with kneading disc 3 and rotating, the gland 5 that is arranged on kneading bucket 4, on the said gland 5 A screw mandrel 11 is provided; a fixed bracket 6 fixed on the kneading barrel 4 is provided, and four support rods 7 are arranged on the fixed bracket 6; the two support rods 7 in front of the four support rods 7 are A cantilever 8 is respectively connected between the two support rods 7 in the middle and rear, and two guide rails 9 parallel to each other are connected between the two cantilever arms 8; a connecting arm movable along the guide rail is arranged between the two guide rails 9 20;

[0020] The connecting arm 20 is provided with a nut sleeve 10 matched with the screw rod 11 in the middle; the nut sleeve 10 is connected with a first drive structure for driving the screw rod 11 to mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com