Water cyclone dust removal system

A technology of cyclone dust removal and air duct, which is applied in the direction of dispersed particle separation, chemical instruments and methods, and the use of liquid separation agents, etc., can solve the problems of unsuitable for general application, large footprint, high cost, etc., and achieve the best dust removal and purification effect, Improved dust removal efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

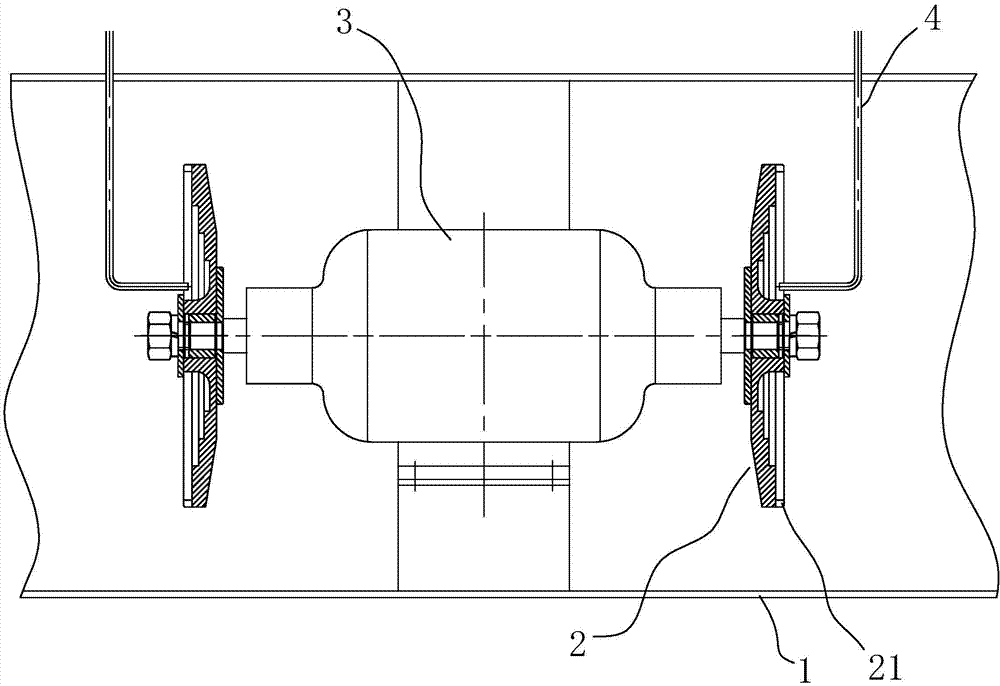

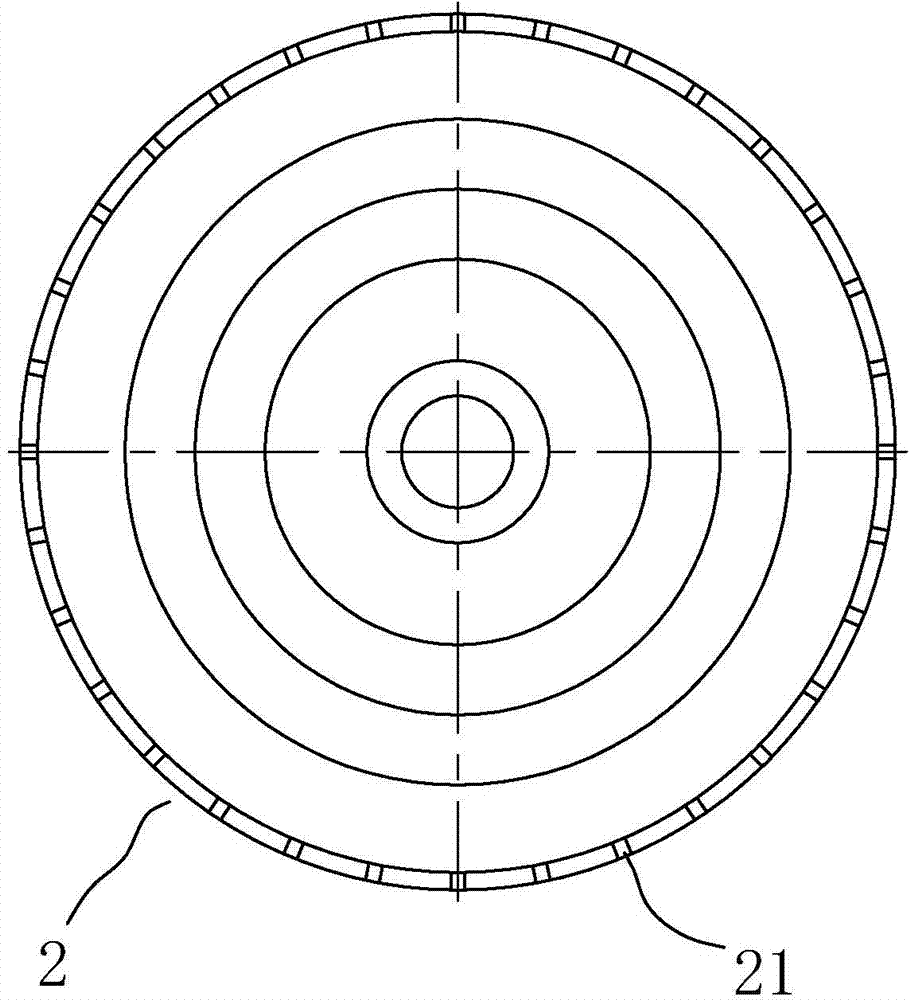

[0015] Embodiment 1: refer to Figure 1 ~ Figure 2 , water cyclone dust removal system, including: dust removal air duct 1, which is provided with a drain port; water throwing tray 2, which is disc-shaped, and one of the disks is concaved to the center to form an arc surface, and the disk is used as a water throwing surface, and the water throwing tray 2. It is arranged in the dust removal air duct 1, and the water rejection surface faces the inlet or outlet direction of the dust removal air duct 1, and the periphery of the water rejection surface stands up to form a vertical wall; There are a plurality of flow diversion tanks 21, which are evenly distributed on the vertical wall; a power device, which is connected with the water throwing tray 2 and can drive it to rotate; a water spraying device, which can supply water to the water throwing surface. The waterproof motor 3 can be fixed conveniently by setting a bracket in the dust removal air duct 1 . The drain can be special...

Embodiment 2

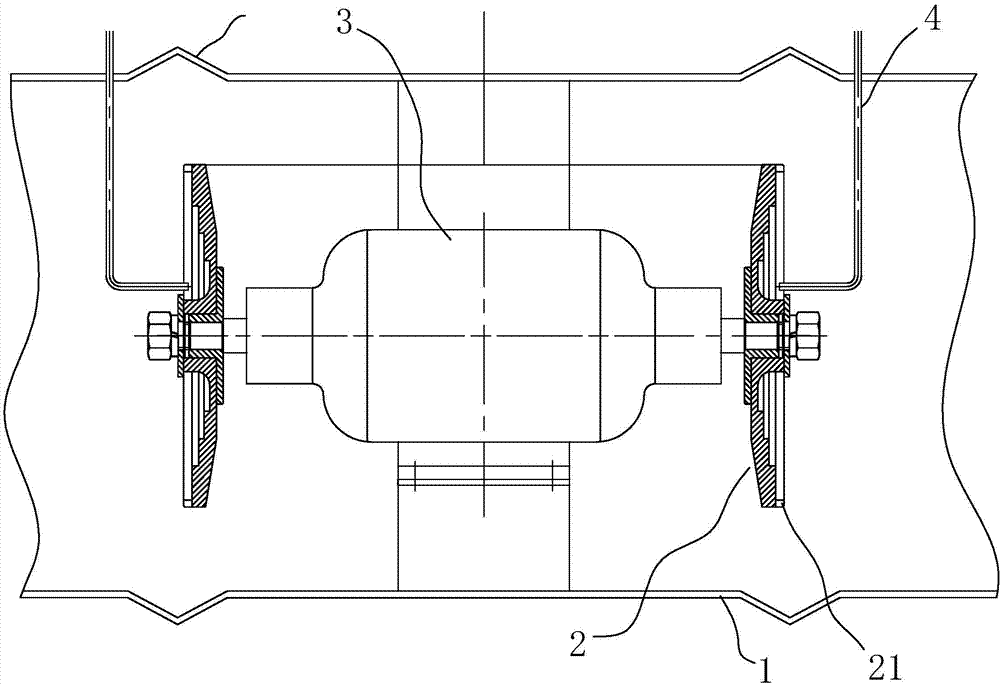

[0022] Embodiment 2: refer to figure 2 and image 3 In the case of the same basic structure as that of Embodiment 1, in the radial circumferential space of the water throwing pan 2, there are provided for meeting the impact of the water flow thrown out from the splitter groove 21 and making the water flow bounce back, Sputtering into the inclined slope structure of the space in front of the water jet. Specifically, the dust removal air duct 1 has at least one section of an inner wall that is "V"-shaped in axial cross-section, with the pointed corner of the "V" facing outward, and this section of the inner wall serves as the inclined-angle slope structure. Obviously, when the water ring blade hits the V-shaped inner wall at high speed, due to the guidance of the inclined surface, the water mist formed by the broken water droplets will bounce back to the water surface. On the one hand, the water sent by the water pipe per unit time can be fully recycled. On the other hand, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com