a tire

A technology for tires and casings, which is applied to tire parts, non-pneumatic tires, transportation and packaging, etc. It can solve the problems of elasticity and life gap, quality standards are difficult to control, etc., and achieve the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

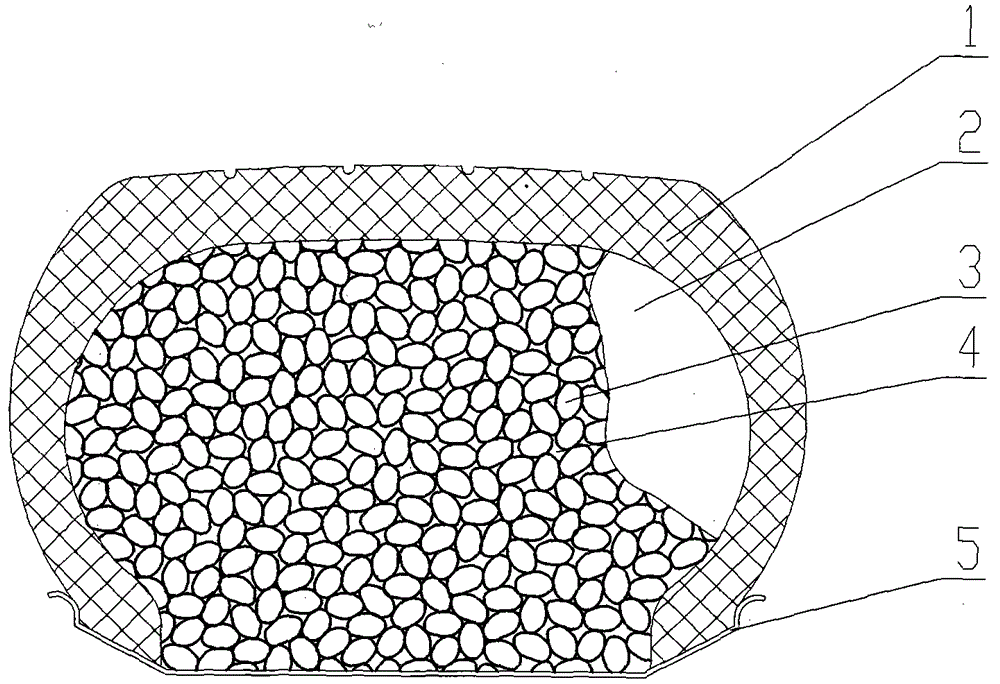

[0017] Specific implementation mode one: as figure 1 As shown, first TPU is made into TPU foamed elastic closed-cell particles 3, put into the space formed by the tire 1 and the rim 5 of the wheel, and countless TPU foamed elastic closed-cell particles 3 are used with adhesive or surface hot-melt ( Such as hot steam) process to bond them together, TPU foamed elastic closed-cell particles 3 fill the space formed by the outer tire 1 and the rim 5, there are gaps 4 between the TPU foamed elastic closed-cell particles 3, forming elastic support inside the tire Body 2, the elastic support body 2 in the tire is solid annular, and the outer tire 1, the rim 5 and the elastic support body 2 in the tire form a whole.

[0018] Commercially available radial tires or bias-ply tires are used as the outer tire 1 and the rim 5, and countless TPU foamed elastic closed-cell particles 3 are bonded together by adhesive or surface hot-melt technology, and the TPU foamed elastic The closed-cell pa...

specific Embodiment approach 2

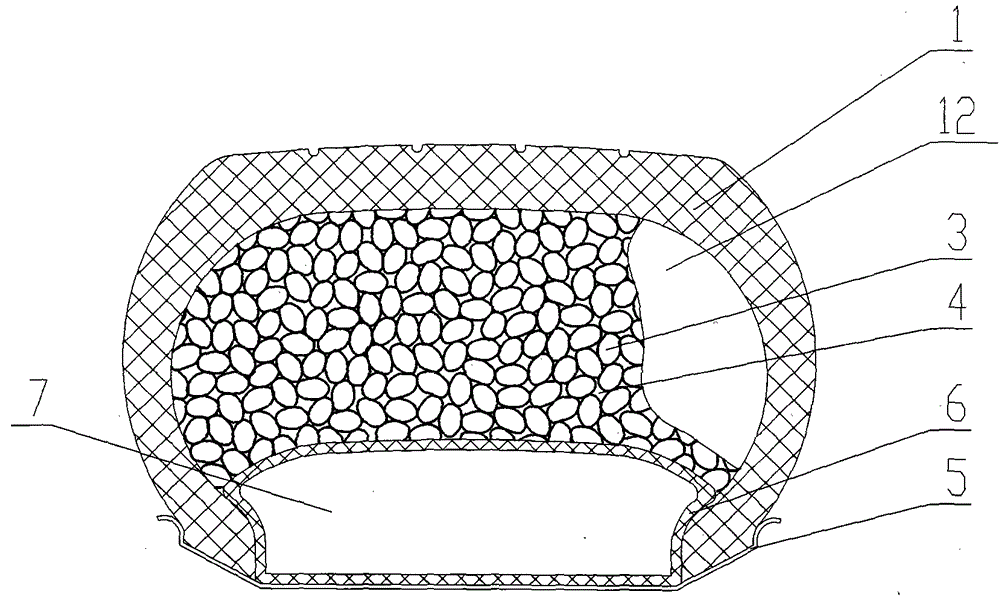

[0019] Specific implementation mode two: as figure 2 As shown, a rubber tire A6 is arranged between the rim 5 and the elastic support body A12 in the tire, the rubber tire A6 is annular and hollow, and the inner cavity A7 is inflated; TPU is made into TPU foamed elastic closed-cell particles 3, put into In the space formed by the outer tire 1 of the wheel and the rubber tire A6, countless TPU foamed elastic closed-cell particles 3 are glued together with an adhesive or a surface hot-melt process, and the TPU foamed elastic closed-cell particles 3 are filled with the outer tire 1 and the space formed by the rubber tire A6, there is a gap 4 between the TPU foamed elastic closed-cell particles 3, forming the elastic support body A12 in the tire, the elastic support body A12 in the tire is a solid ring, the outer tire 1, the rubber tire A6 and the elastic support in the tire The body A12 forms a whole, and the inflation nozzle communicates with the inner cavity A7. The resulting...

specific Embodiment approach 3

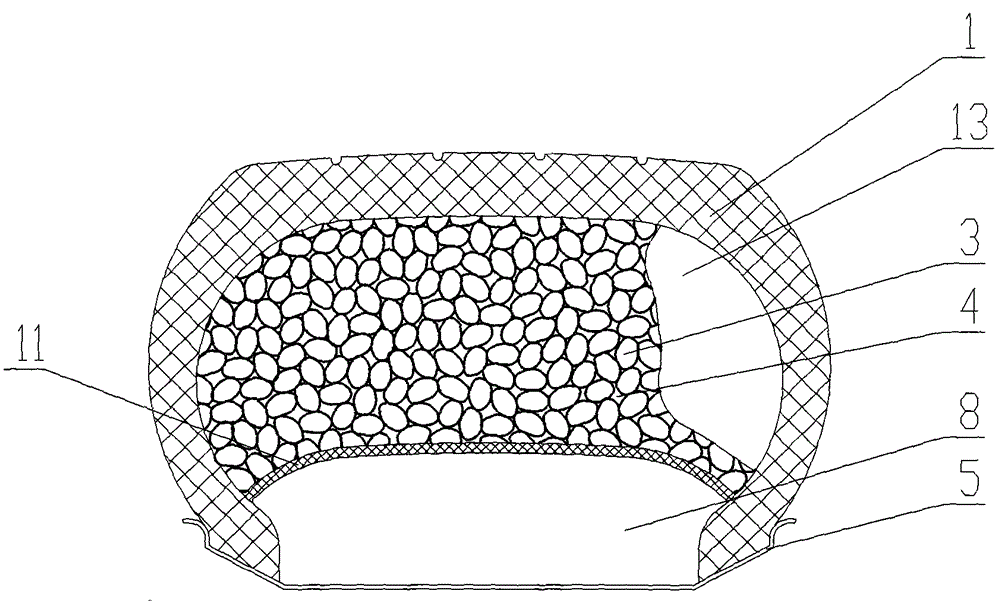

[0020] Specific implementation mode three: as image 3 As shown, the cover tire 1 has a compartment A11, an adhesive or hot-melt is used between the cover tire 1 and the compartment A11, the compartment A11 is annular, and an inner cavity B8 is formed between the cover tire 1, the compartment A11 and the rim 5 , the inner cavity B8 is inflated; the TPU is made into TPU foaming elastic closed-cell particles 3, put into the space formed by the outer tire 1 of the wheel and the compartment A11, and countless TPU foaming elastic closed-cell particles 3 are made of adhesive or surface The process of hot-melt bonding them together, the TPU foamed elastic closed-cell particles 3 fill the space formed by the outer tire 1 and the compartment A11, and there are gaps 4 between the TPU foamed elastic closed-cell particles 3, forming the inner elastic support body B13 , the elastic support body B13 in the tire is solid annular, the outer tire 1, the compartment A11 and the elastic support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com