High-clean aviation alcohol-hydrocarbon composite vehicle fuel additive, preparation method and fuel

A vehicle fuel and additive technology, applied in fuel additives, fuels, liquid carbon-containing fuels, etc., can solve the problems of low concentration of gasoline vapor ignition and explosion, high molecular weight of gasoline, difficulty in suppressing oil-water stratification, etc., and achieve the effect of emission reduction Obvious, high-octane, cost-saving effect on fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

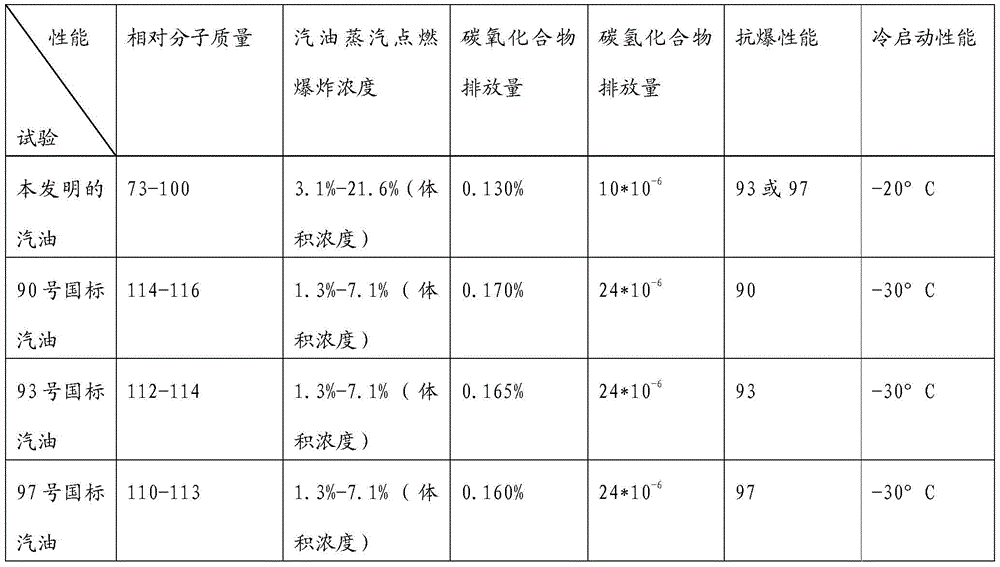

Examples

Embodiment 1

[0045] A high-clean aviation alcohol-hydrocarbon composite vehicle fuel additive, prepared from the following raw materials in parts by weight: 0.1 parts of petroleum ether, 18 parts of n-butanol, 2 parts of methanol, 3 parts of acetone, 1.8 parts of tert-butanol, 12 3.5 parts of alcohol, 2 parts of 2-6 di-tert-butyl-4-methylphenol, 1.4 parts of AH-BSF-217 copper corrosion inhibitor, 4.5 parts of isopropyl ether, 2 parts of cyclopentadiene manganese tricarbonyl and CH agent 1.5 servings.

[0046] A preparation method of the above-mentioned high-clean aviation alcohol-hydrocarbon composite vehicle fuel additive, the above-mentioned raw materials are prepared according to petroleum ether, n-butanol, methanol, acetone, tert-butanol, dodecyl alcohol, 2-6 di-tert-butyl -4-Methylphenol, copper corrosion inhibitor, isopropyl ether, cyclopentadienyl manganese tricarbonyl, and CH agent are mixed sequentially to form a mixed solution, which is passed into a circulation pump for thorough...

Embodiment 2

[0049] A high-clean aviation alcohol-hydrocarbon composite vehicle fuel additive is prepared from the following raw materials in parts by weight: 0.12 parts of petroleum ether, 25 parts of n-butanol, 15 parts of methanol, 8 parts of acetone, 10 parts of tert-butanol, 6 parts of alcohol, 4 parts of 2-6 di-tert-butyl-4-methylphenol, 2 parts of AH-BSF-217 copper corrosion inhibitor, 10 parts of isopropyl ether, 3 parts of cyclopentadiene manganese tricarbonyl and CH agent 3 copies.

[0050] A preparation method of the above-mentioned high-clean aviation alcohol-hydrocarbon composite vehicle fuel additive, the above-mentioned raw materials are prepared according to petroleum ether, n-butanol, methanol, acetone, tert-butanol, dodecyl alcohol, 2-6 di-tert-butyl -4-Methylphenol, copper corrosion inhibitor, isopropyl ether, cyclopentadienyl manganese tricarbonyl, and CH agent are mixed sequentially to form a mixed solution, which is passed into a circulation pump for thorough mixing, ...

Embodiment 3

[0053] A high-clean aviation alcohol-hydrocarbon composite vehicle fuel additive, prepared from the following raw materials in parts by weight: 0.1-0.15 parts of petroleum ether, 39 parts of n-butanol, 25 parts of methanol, 14 parts of acetone, 19 parts of tert-butanol, 8.5 parts of dodecyl alcohol, 7 parts of 2-6 di-tert-butyl-4-methylphenol, 4.8 parts of AH-BSF-217 copper corrosion inhibitor, 16 parts of isopropyl ether, 5 parts of cyclopentadiene manganese tricarbonyl and CH agent 4 parts.

[0054] A preparation method of the above-mentioned high-clean aviation alcohol-hydrocarbon composite vehicle fuel additive, the above-mentioned raw materials are prepared according to petroleum ether, n-butanol, methanol, acetone, tert-butanol, dodecyl alcohol, 2-6 di-tert-butyl -4-Methylphenol, copper corrosion inhibitor, isopropyl ether, cyclopentadienyl manganese tricarbonyl, and CH agent are mixed sequentially to form a mixed solution, which is passed into a circulation pump for tho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com