Spray drying method for purifying LiAlH4

A spray drying method and drying technology, which is applied in the field of purifying LiAlH4, can solve the problems that limit the application of LiAlH, achieve good air tightness, high purity, and expand the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

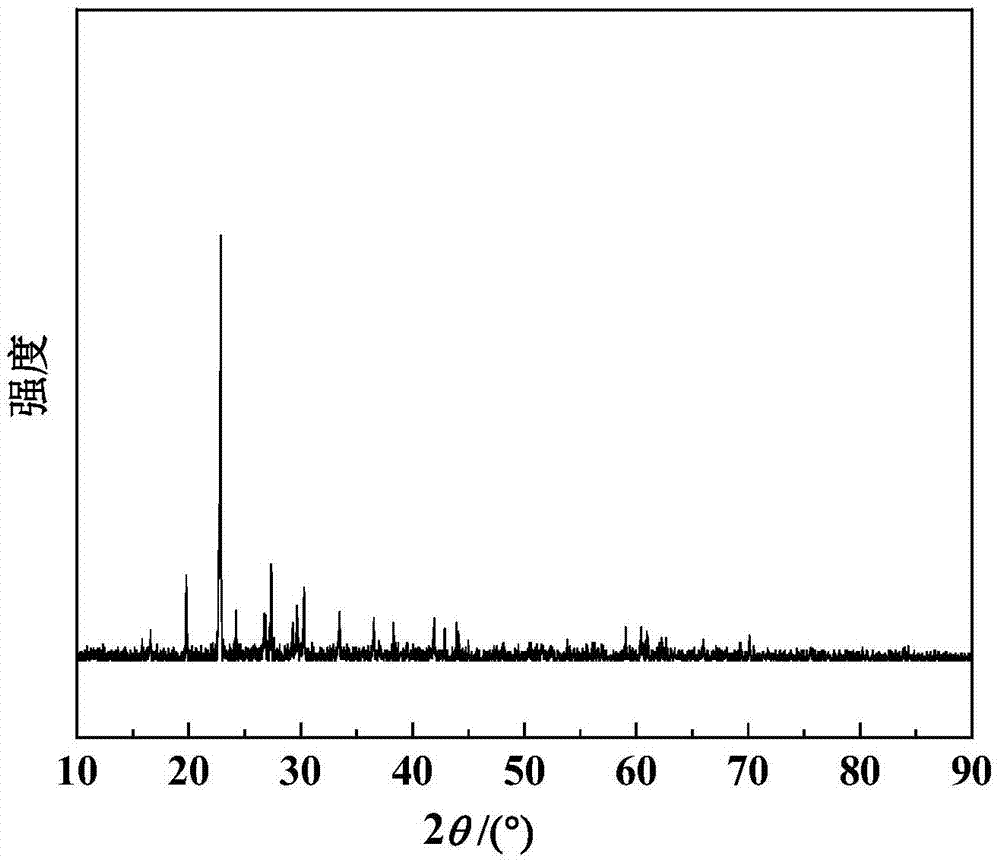

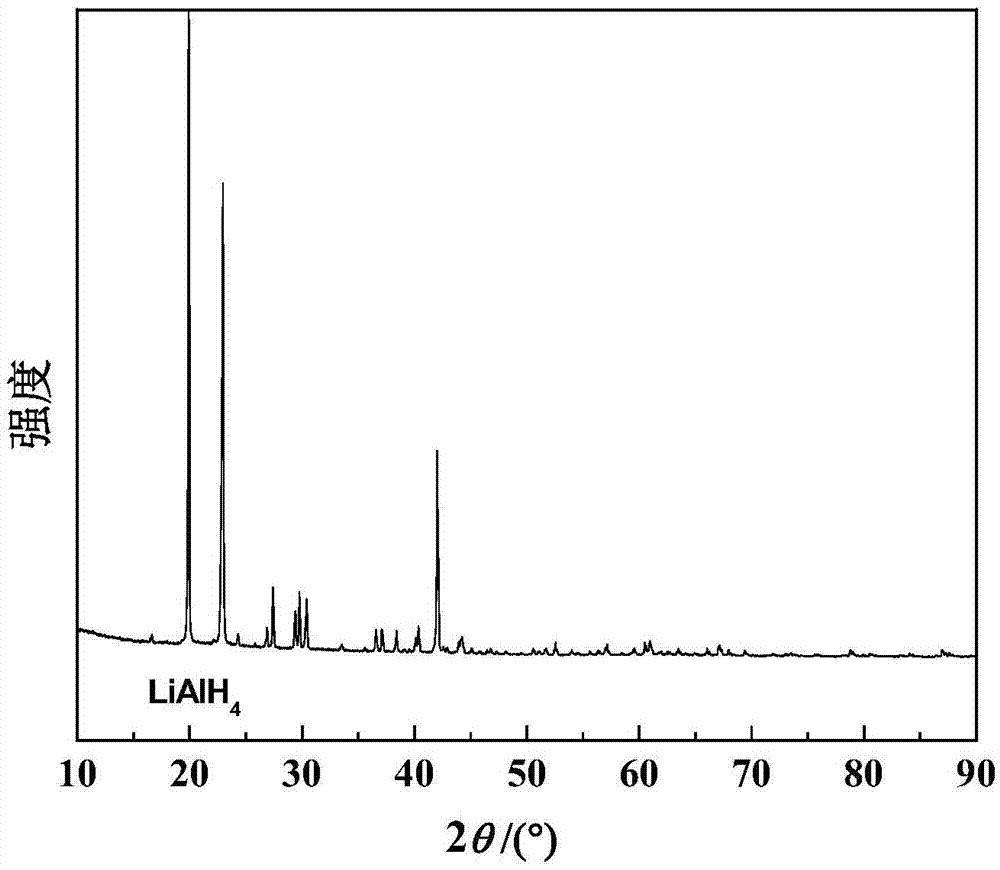

[0017] Embodiment 1: The spray drying method described in this embodiment purifies LiAlH 4 method, which includes the following steps:

[0018] Step 1. Add unpurified LiAlH to the container 4 , while stirring, slowly add anhydrous ether to obtain a mixed solution;

[0019] Step 2, filter the mixed solution obtained in step 1 with a sand core funnel to obtain a filtrate;

[0020] Step 3, spray-dry the filtrate obtained in step 2 with spray drying equipment to obtain purified LiAlH 4 ;

[0021] The steps one, two and three are all carried out under anhydrous and oxygen-free conditions.

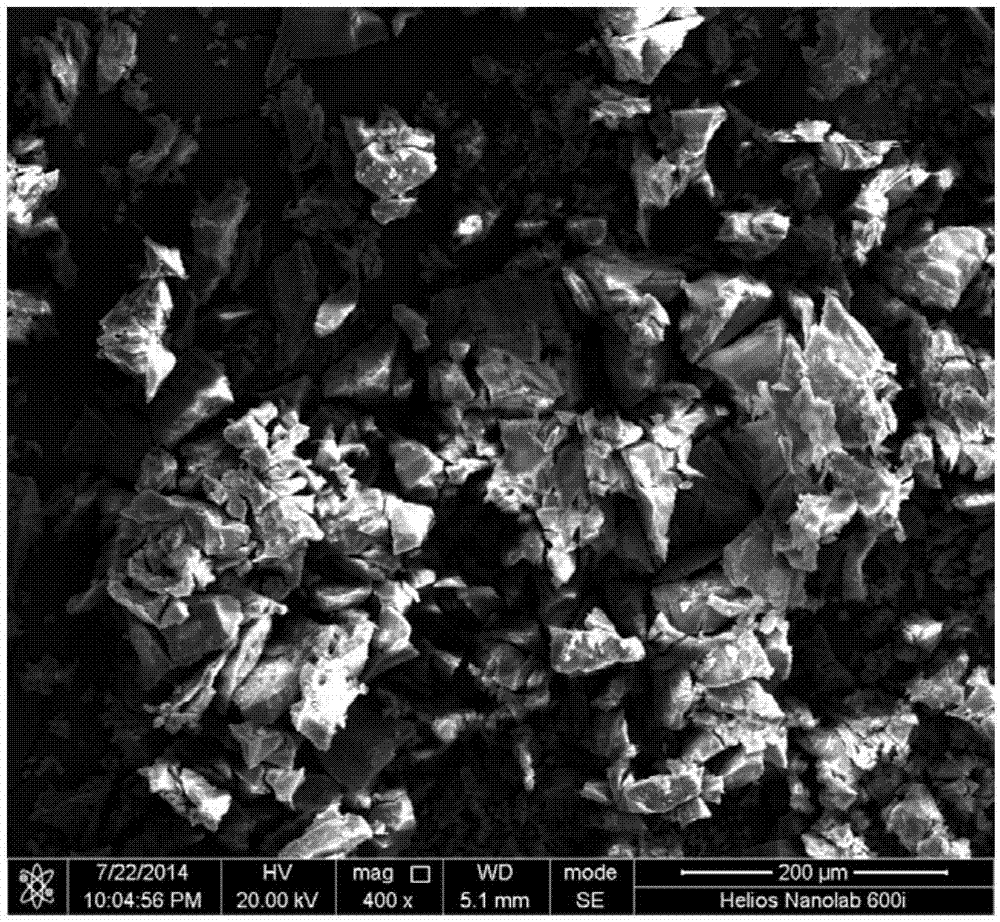

[0022] In this embodiment, low-cost industrial-grade LiAlH is used 4 As a raw material, LiAlH was dried by filtration under mild conditions with spray drying equipment 4 Diethyl ether solution, fast spray drying rate, obtains LiAlH with high purity, high yield and good crystallinity 4 , is LiAlH 4 It provides a basis for large-scale purification applications, and has a very broad market ...

specific Embodiment approach 2

[0023] Specific embodiment 2: This embodiment is to purify LiAlH by the spray drying method described in specific embodiment 1 4 In this embodiment, in step 3, the flow rate of the nozzle of the spray drying equipment is 1.1L / h~1.4L / h.

specific Embodiment approach 3

[0024] Embodiment 3: This embodiment is to purify LiAlH by the spray drying method described in Embodiment 1 or 2 4 In this embodiment, in step 3, the inlet temperature of the spray drying equipment is 42°C to 48°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com