Preparation method of explosion-proof glass cover plate and smart touch desktop assembly

A technology of explosion-proof glass and desktop components, which is applied in glass manufacturing equipment, glass tempering, manufacturing tools, etc., can solve problems such as easy interference and weak protection ability, and achieve improved protection level and safety performance, high corrosion resistance level, Good protective barrier effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] A method for preparing an explosion-proof glass cover plate, comprising the steps of:

[0018] S1. Put the original glass sheet with a thickness greater than 6mm into the tempering furnace and slowly heat it to 620-640°C;

[0019] S2. Insulating the heated glass;

[0020] S3, quenching the glass until the temperature of the inner layer of the glass drops to 500°C.

[0021] From the above description, it can be seen that the beneficial effect of the present invention lies in that the preparation method of the explosion-proof glass cover of the present invention is simple, and the prepared glass cover has the characteristics of anti-violence, waterproof, and high corrosion resistance, and can also combine with the split-screen technology to solve the multi-screen simultaneous Driver interference.

[0022] Further, in the step S1, after the original glass sheet is put into the tempering furnace, the temperature in the tempering furnace gradually rises from room temperatu...

Embodiment 1

[0036] Embodiment 1 of the present invention is: a method for preparing an explosion-proof glass cover plate, comprising the steps of:

[0037] S1. Put the original glass sheet with a thickness of 6.5mm into the tempering furnace and slowly heat it to 640°C; specifically, after the original glass sheet is placed in the tempering furnace, the temperature in the tempering furnace gradually rises from room temperature to 640°C.

[0038] The heating process of glass can be divided into two stages:

[0039] S11. Heating stage: The glass sheet enters the tempering furnace from room temperature to be heated. Since glass is a poor conductor of heat, the surface temperature of the glass is high at this time, and the surface begins to expand, but the interior does not expand, so the expansion of the surface layer is affected by the central layer. Inhibition, the surface layer has a temporary compressive stress, and the central layer is a tensile stress.

[0040] S12. Continuous heating...

Embodiment 2

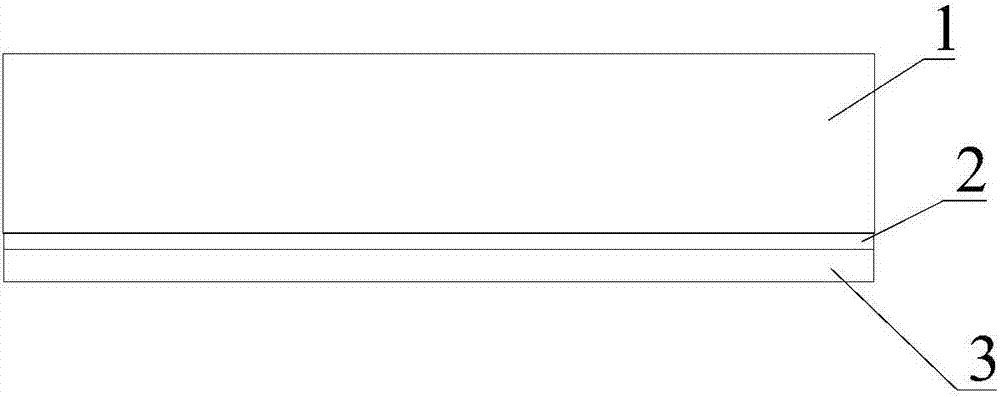

[0050] Please refer to figure 1, the present embodiment is an intelligent touch desktop assembly, including the explosion-proof glass cover plate 1 prepared by the method described in Embodiment 1, and also includes a nano-metal circuit layer 2 and a liquid crystal display 3, and the nano-metal circuit layer 2 is arranged between the explosion-proof glass cover 1 and the liquid crystal display 3; the explosion-proof glass cover 1 is sealed and bonded to the nano-metal circuit layer 2. Preferably, the explosion-proof glass cover plate 1 has a thickness of 6.5 mm; the nano-metal circuit layer 2 is a nano-silver circuit layer, and the thickness of the nano-silver circuit layer is 0.045 mm.

[0051] The nano-metal circuit layer 2 is printed on the back of the explosion-proof glass cover plate 1 by screen printing.

[0052] The smart touch desktop component also includes a rubber frame and a hard frame, the hard frame is arranged around the explosion-proof glass cover 1 , and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com