Tire with automatic repair function

An automatic repair and tire technology, applied in tire parts, reinforcement layers of pneumatic tires, transportation and packaging, etc., can solve problems such as the inability to prevent rapid tire leakage or tire blowout, and achieve faster overall air leakage. Simple structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

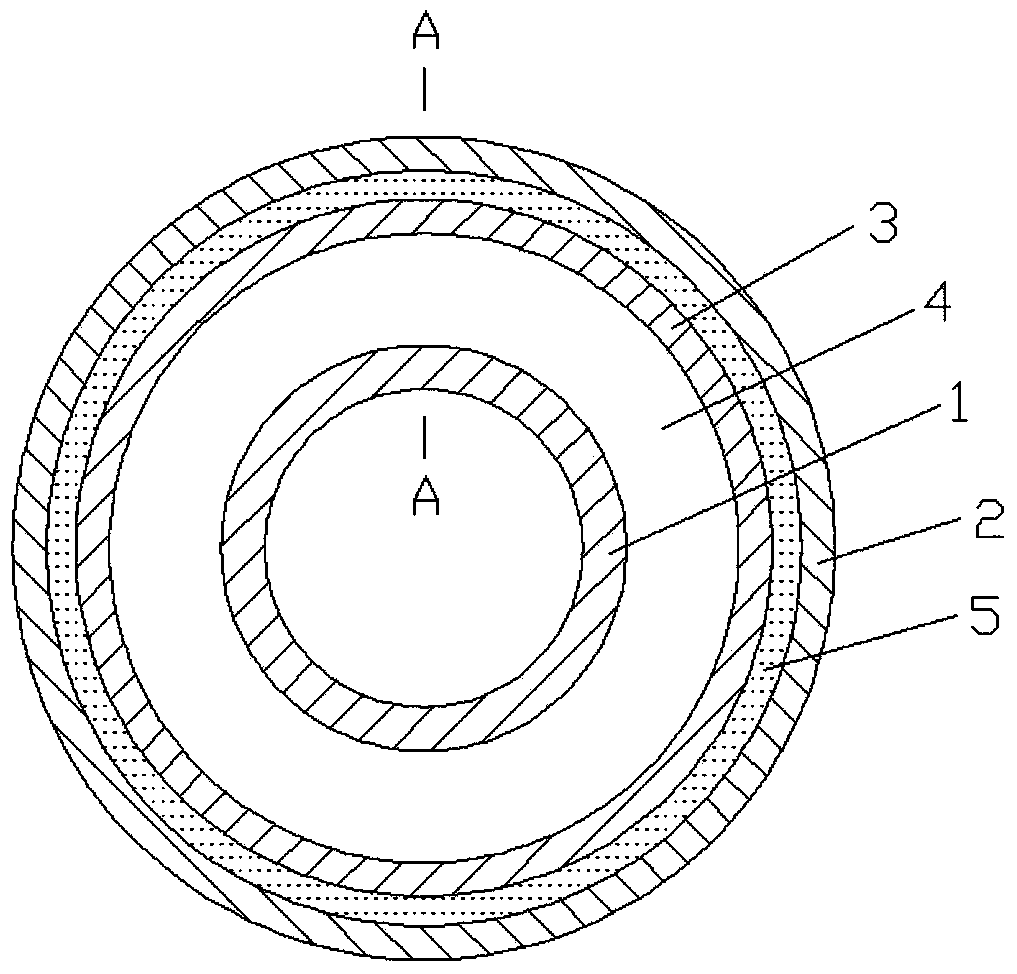

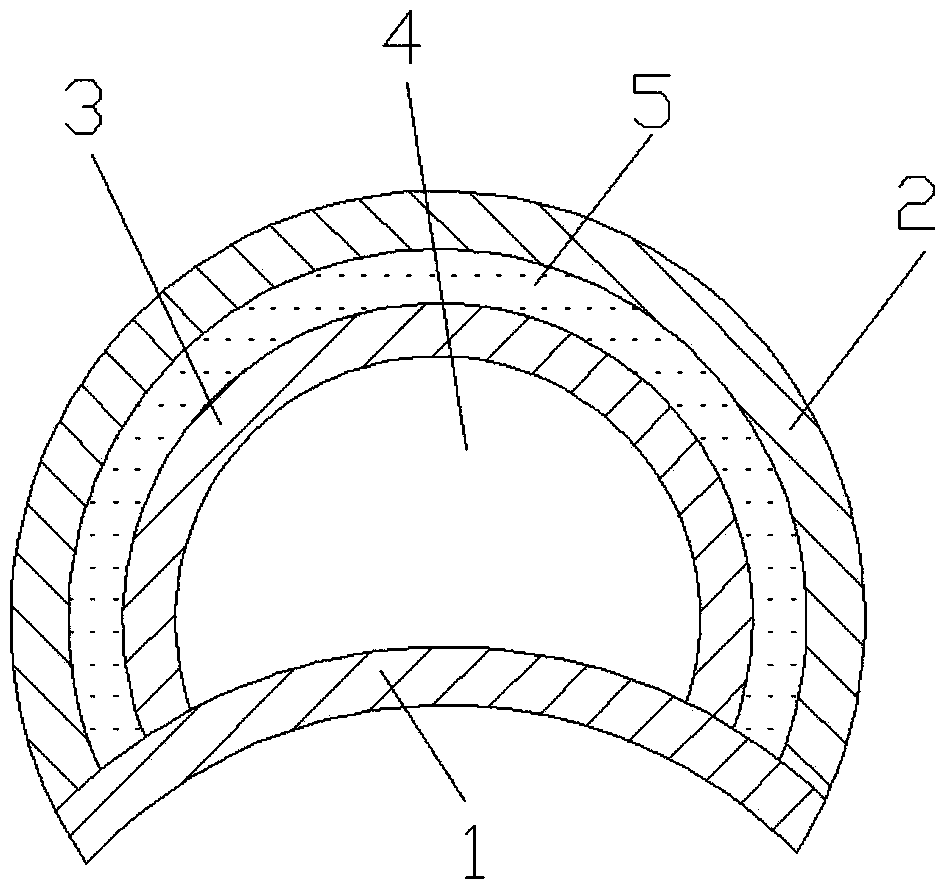

[0012] Examples of the present invention are Figure 1 to Figure 2 Shown, the present invention comprises wheel hub 1, cover tire 2, inner tube of a tube 3, air bag 4, solid glue layer 5, cover tire 2 is arranged on the outer edge of tire, and wheel hub 1 is arranged on the inner edge of tire, and cover tire 2, inner tube of a tube 3 are all connected with wheel hub 1 Connected together, the airbag 4 is formed by the space between the inner tube 3 and the wheel hub 1, the longitudinal sections of the outer tire 2 and the inner tube 3 are circular, the solid adhesive layer 5 is arranged between the outer tire 2 and the inner tube 3, and the solid adhesive layer 5 Connected with the hub 1, the longitudinal section of the solid adhesive layer 5 is circular.

[0013] During the implementation of the present invention, the solid glue layer 5 is arranged in the tire, and because it is solid, it will not also slide inside the tire when the tire rotates. When the nail was inserted in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com