Double -level disassembly split force

A technology for power take-offs and differentials, applied in control devices, auxiliary drive devices, transportation and packaging, etc., can solve the problems of insufficient installation space, reduce production costs, etc., achieve complete functions, reduce production costs, and ensure safety clearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

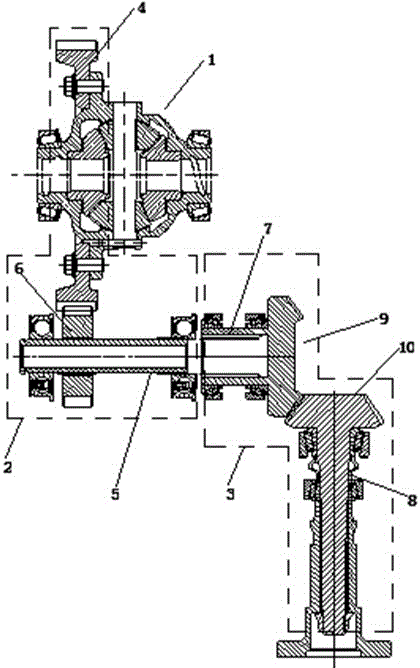

[0032] Example 1 A two-stage detachable power take-off

[0033] The present embodiment takes power from the transmission with differential 1 .

[0034] Such as figure 2 As shown, this embodiment includes a primary power take-off unit 2 and a secondary power take-off unit 3 , the power output end of the primary power take-off unit 2 and the power input end of the secondary power take-off unit 3 are coaxially linked. in:

[0035] (1) Primary power take-off unit 2

[0036] The primary power take-off unit 2 and the transmission are integrated in the first housing (not shown in the figure).

[0037] The primary power take-off unit 2 includes the ring gear of the differential 1 , that is, the differential ring gear 4 , an intermediate shaft 5 and a primary driven cylindrical gear 6 arranged on the intermediate shaft 5 . The primary driven cylindrical gear 6 meshes with the differential ring gear 4

[0038] The intermediate shaft 5 is arranged parallel to the central axis of th...

Embodiment 2

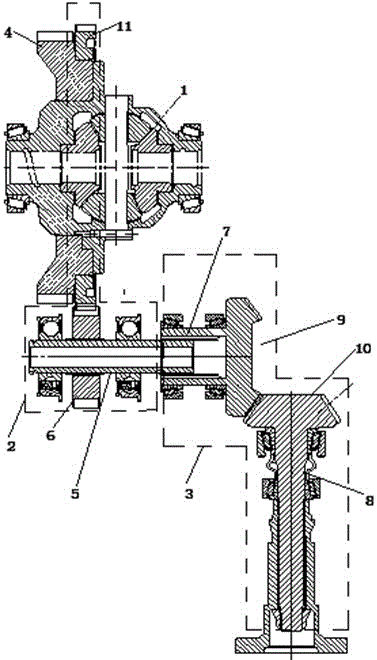

[0049] Embodiment 2 A two-stage detachable power take-off

[0050] The present embodiment takes power from the transmission with differential 1 .

[0051] Such as image 3 As shown, this embodiment includes a primary power take-off unit 2 and a secondary power take-off unit 3 , the power output end of the primary power take-off unit 2 and the power input end of the secondary power take-off unit 3 are coaxially linked. in:

[0052] (1) Primary power take-off unit 2

[0053] The primary power take-off unit 2 and the transmission are integrated in the first housing (not shown in the figure).

[0054]The primary power take-off unit 2 includes a linkage gear 11 arranged on the differential 1 , and also includes an intermediate shaft 5 and a primary driven cylindrical gear 6 arranged on the intermediate shaft 5 .

[0055] The intermediate shaft 5 is arranged parallel to the central axis of the differential ring gear 4, and is a hollow horizontal shaft. The left and right ends of...

Embodiment 3

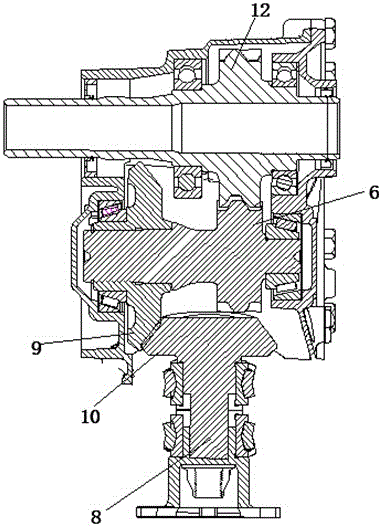

[0067] Embodiment 3 A two-stage detachable power take-off

[0068] The present embodiment takes power from the transmission with differential 1 .

[0069] Such as Figure 4 As shown, this embodiment includes a primary power take-off unit 2 and a secondary power take-off unit 3 , the power output end of the primary power take-off unit 2 and the power input end of the secondary power take-off unit 3 are coaxially linked. in:

[0070] (1) Primary power take-off unit 2

[0071] The primary power take-off unit 2 and the transmission are integrated in the first housing (not shown in the figure).

[0072] The primary power take-off unit 2 includes a primary driving cylindrical gear 12 set on the housing of the differential 1 and linked with the differential ring gear 4, and also includes an intermediate shaft 5 and a primary driven cylindrical gear arranged on the intermediate shaft 5. gear 6.

[0073] The intermediate shaft 5 is arranged parallel to the central axis of the diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com