Railway vehicle bogie axle end sealing structure

A technology for bogie shafts and rail vehicles, applied in the field of rail vehicle bogie shaft end structures and shaft end sealing structures, can solve problems such as axle shaft end sealing problems, and achieve the advantages of overcoming installation problems, convenient installation and disassembly, and ingenious and reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

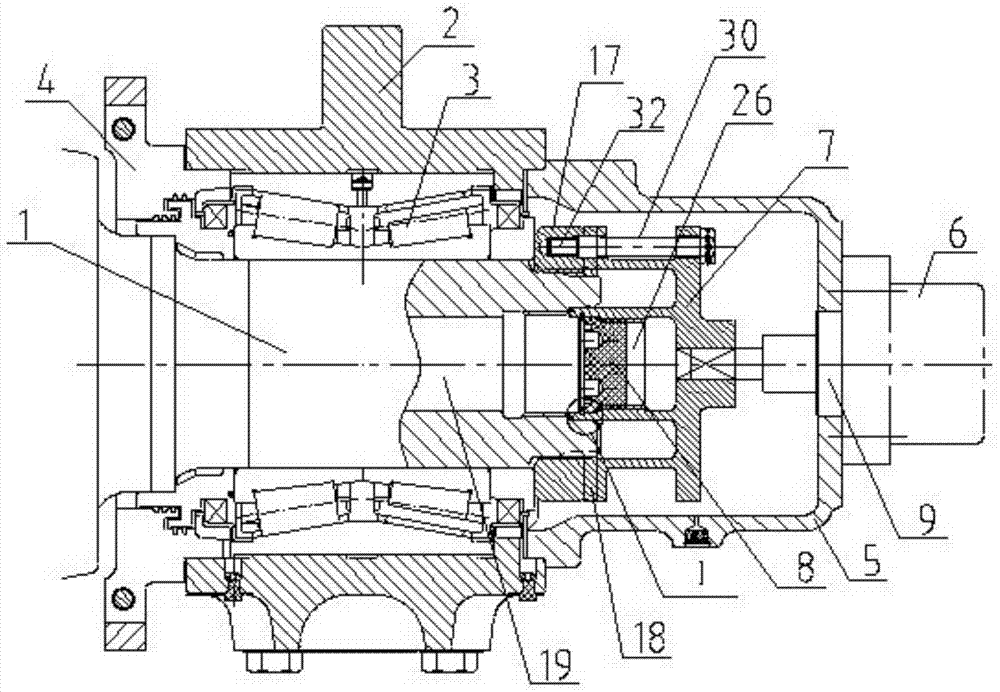

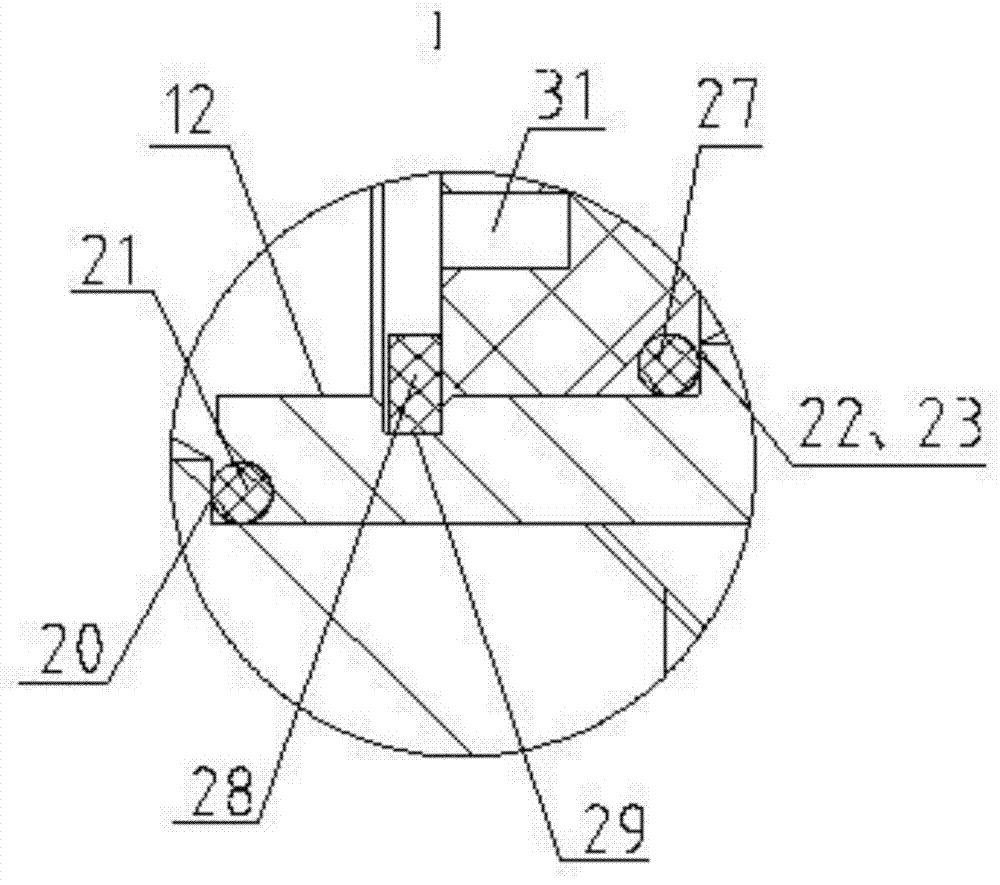

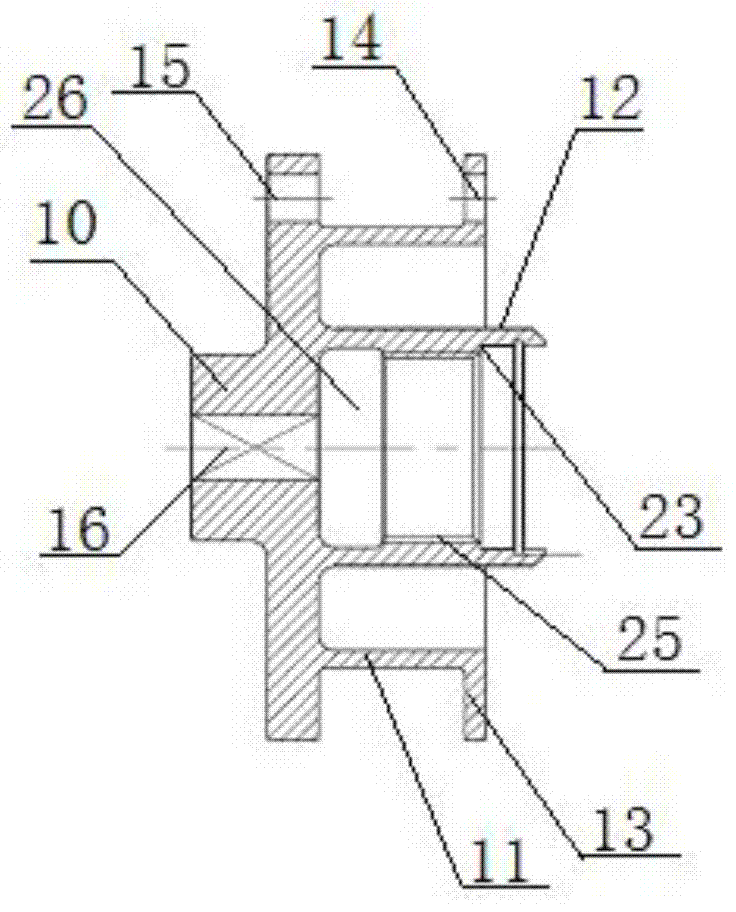

[0024] like figure 1 As shown, the present invention provides a rail vehicle bogie shaft end sealing structure, which is mainly used in the comprehensive detection EMU, and the corresponding sensor 6 can be installed on the shaft end of the hollow axle 1 according to the needs of the detection function.

[0025] The shaft end sealing structure includes a hollow axle 1, a pair of wheels (not shown in the figure) are arranged at the two ends of the hollow axle 1, and an axle box 2 is installed at the end of the hollow axle 1. The neck is connected with the axle box body 2 through the bearing 3, and the axle box rear cover 4 and the axle box front cover 5 are connected on both sides of the axle box body 2, and the sensor 6 for detection is fixedly installed on the axle box front cover 5, A transition gland 7 and a dust cover 8 are also installed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com