A method for large-scale cultivation of microalgae

A microalgae and flow channel technology, applied in the field of large-scale cultivation of microalgae, can solve the problems of low photosynthetic efficiency and light energy utilization rate of microalgae, and achieve the effect of improving light energy utilization rate and photosynthetic efficiency, and increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

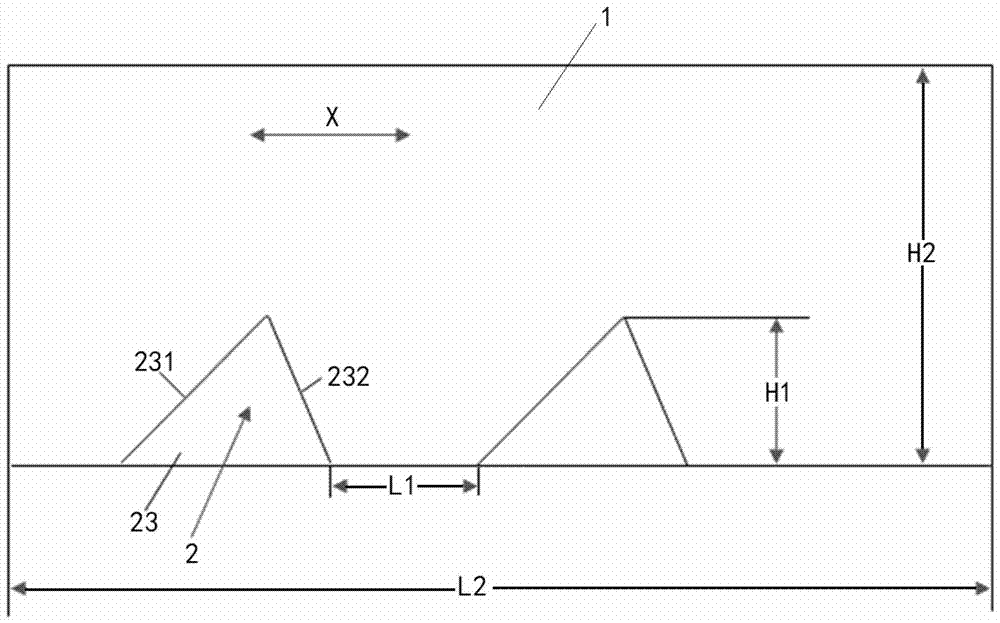

[0031]In the first preferred embodiment, the first side 231 and the second side 232 are straight sides, and the flow velocity of the liquid containing microalgae is 0.5-2.5 m / s.

[0032] In the second preferred embodiment, the first side 231 and the second side 232 are concave curved sides, and the flow velocity of the liquid containing microalgae is 0.3-2m / s; more preferably, the first side 231 has a first radius of curvature, The second side 232 has a second radius of curvature, the first radius of curvature is greater than or equal to the second radius of curvature; more preferably, the first radius of curvature is 2-10 times the height H1 of the spoiler 2, and the second radius of curvature is 1-5 times of the height H1 of the flow part 2 .

[0033] Those skilled in the art should understand that the concave curved side means that relative to the spoiler section 23, the curved side is concave to the inside of the spoiler section 23, such as Figure 4 In (b) shown.

[003...

Embodiment 1

[0057] This example is used to illustrate the method for the large-scale cultivation of microalgae of the present invention.

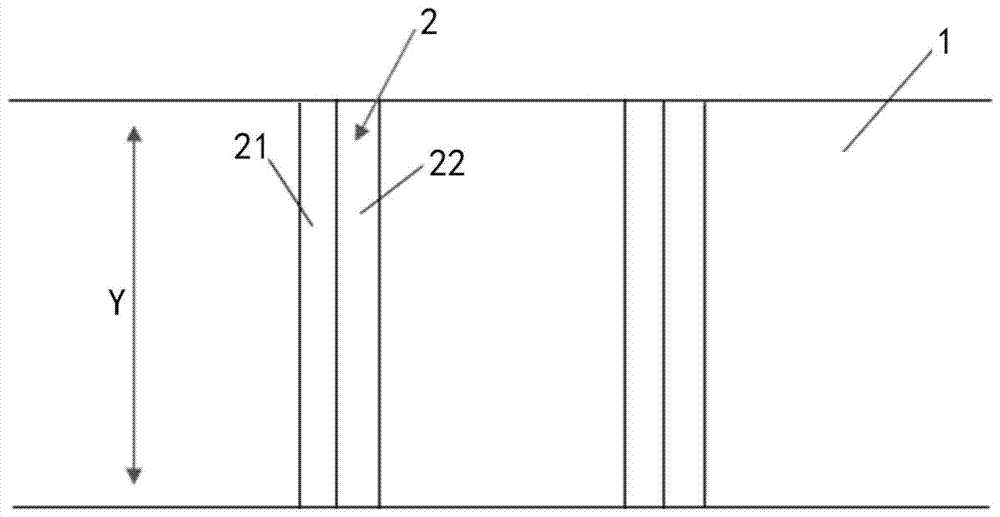

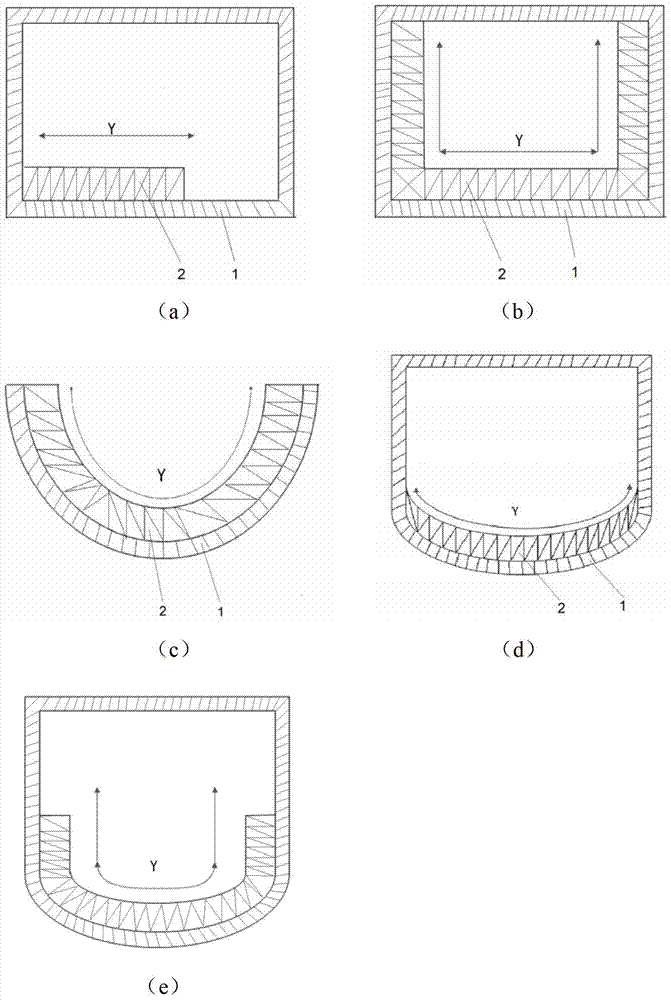

[0058] Grow chlorella under natural light. The photobioreactor consists of upper and lower flow channels 1, a liquid storage tank and a circulation pump. The flow channels 1 are all effective light surface areas. Each flow channel 1 is 150 cm long, 10 cm wide, and 5 cm thick. There is no inclination angle, and the flow The bottom surface of the channel 1 is a non-light-proof surface, and 10 spoilers 2 are arranged on the non-light-proof surface of each channel 1. The spoiler 2 is formed by extending the spoiler section 23 along the first direction Y. The spoiler section 23 It is a triangle, including a first side 231, a second side 232 and a third side 233. The first side 231, the second side 232 and the third side 233 extend along the first direction Y to form the first spoiler surface 21 and the second side respectively. The spoiler surface 22 and t...

Embodiment 2

[0060] This example is used to illustrate the method for the large-scale cultivation of microalgae of the present invention.

[0061]Grow Chlorella under natural light. The photobioreactor consists of upper and lower flow channels 1, a liquid storage tank and a circulation pump. The flow channels 1 are all effective light surface areas. Each flow channel 1 is 150 cm long, 10 cm wide, and 15 cm thick. The inclination angle of the flow channel is 1 degree, the bottom surface of the flow channel 1 is a non-light-proof surface, and 10 spoilers 2 are arranged on the non-light-proof surface of each flow channel 1, and the spoiler 2 is formed by extending the spoiler section 23 along the first direction Y, The spoiler section 23 is triangular, including a first side 231, a second side 232 and a third side 233, and the first side 231, the second side 232 and the third side 233 extend along the first direction Y to form a first spoiler surface respectively 21. The second turbulent sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com