Correcting system and correcting method of leather cutter

A calibration system and cutting machine technology, which is applied in the field of calibration systems for leather cutting machines, can solve problems such as large errors, and achieve the effects of avoiding waste, accurate leather size, and fast calibration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

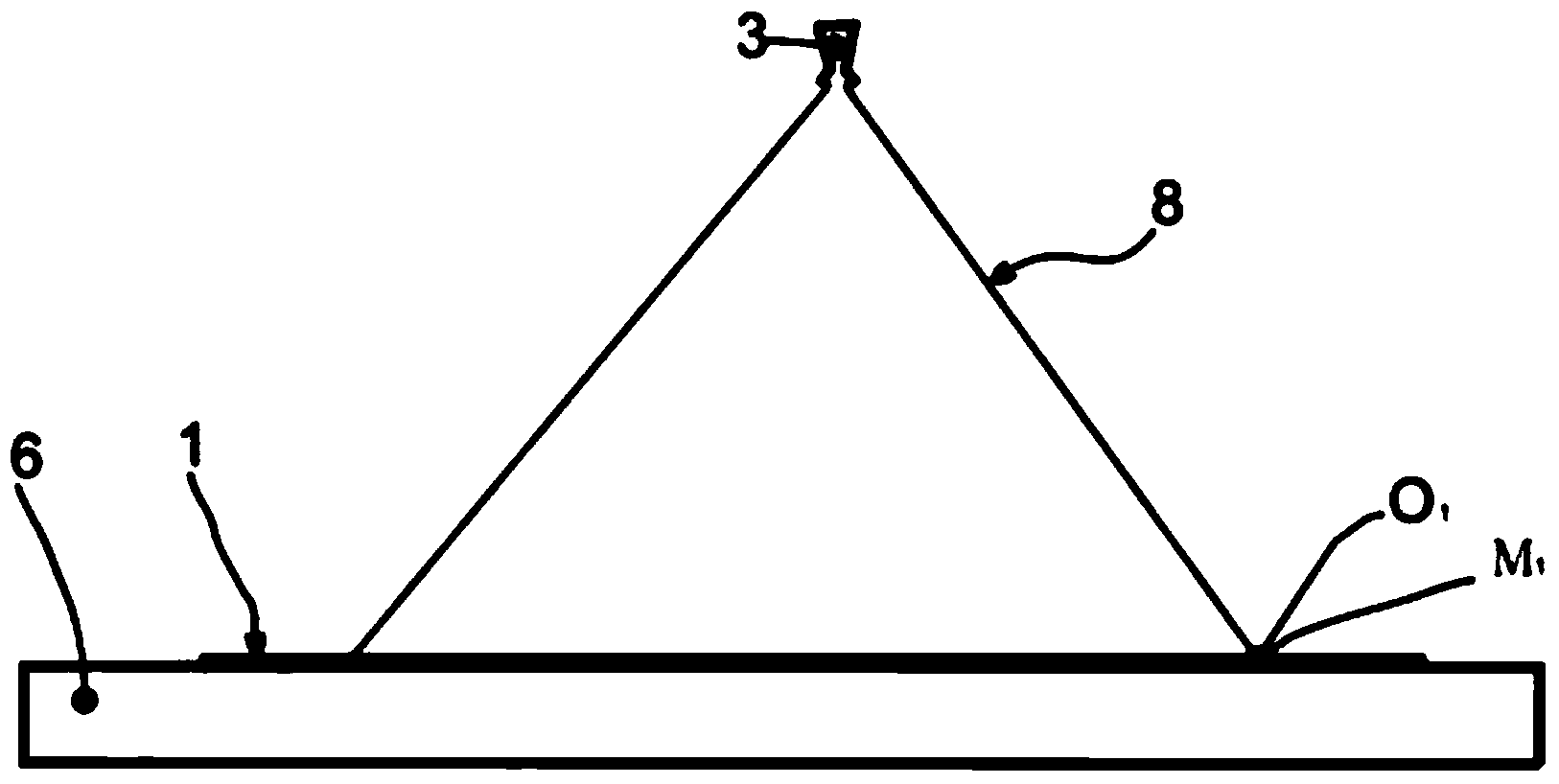

[0032] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0033] like Figure 1-6 As shown, a calibration system for a leather cutting machine includes a calibration board 1, a calibration module 2, a projector 3 and a computer,

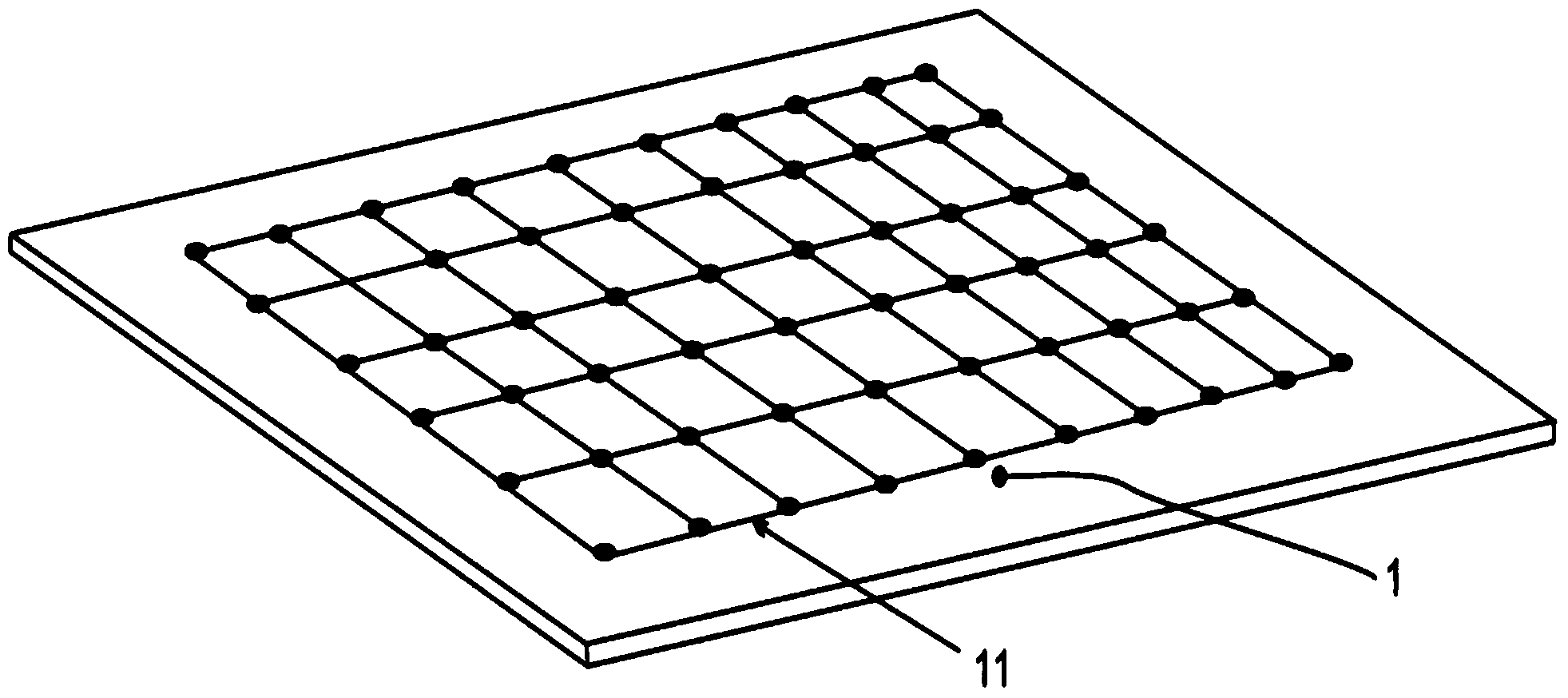

[0034] Described correction plate 1 is the equal thickness thin plate that is tiled on workbench 6, and upper surface is provided with correction point (such as figure 1 shown);

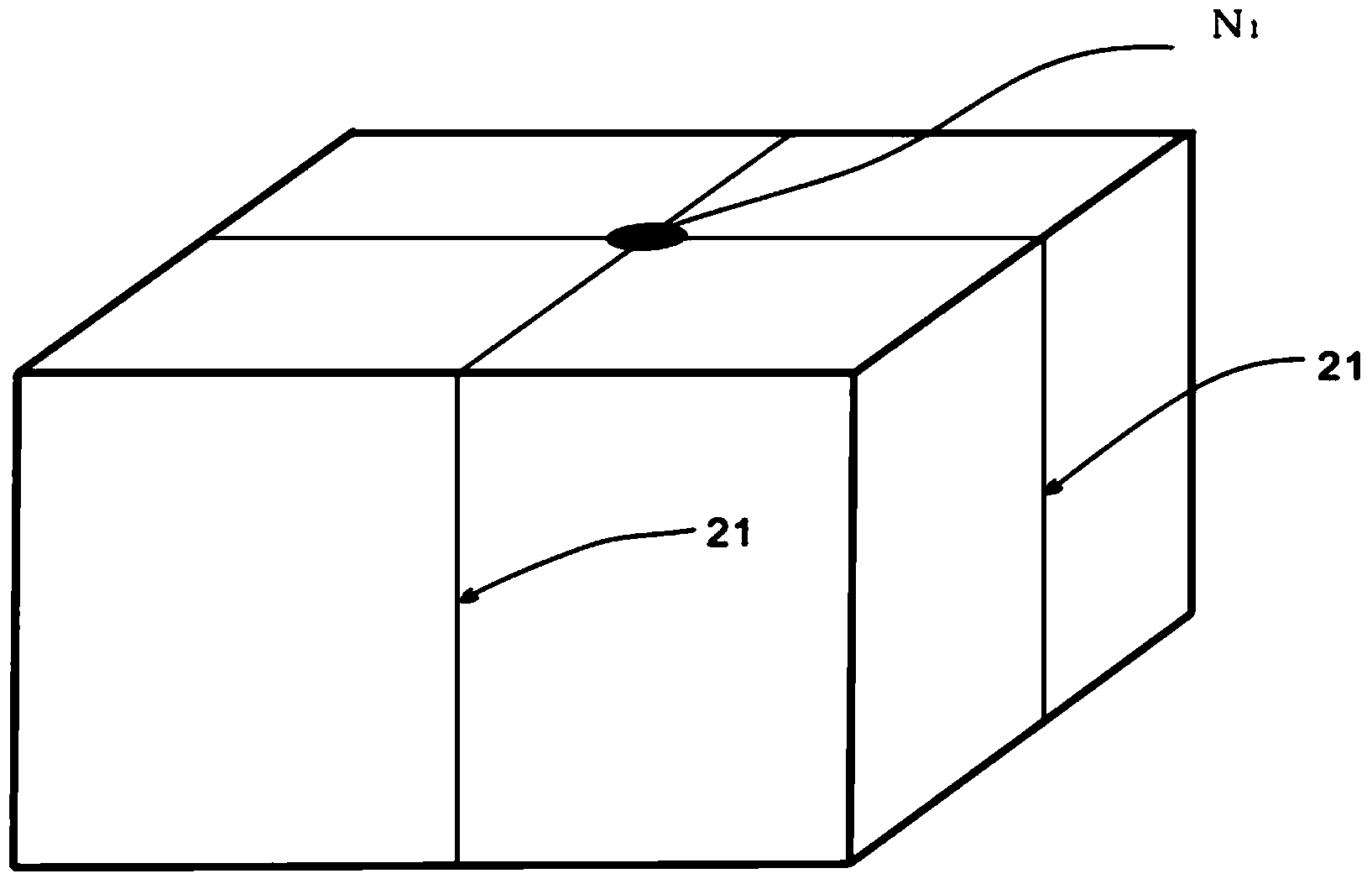

[0035] The correction module 2 is a rigid body parallel to the upper and lower sides, with a thickness of H 1 , for placing on the correction board 1 for correction, and the upper surface of the correction module 2 is provided with module points for correction (such as figure 2 shown), the calibration module 2 is placed on the upper surface of the calibration board 1 so that the module points are aligned with the calibration points;

[0036] The pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com