Hollow slab bridge structure with end floor beams and construction method thereof

A technology of hollow slab bridge and construction method, which is applied to bridges, bridge parts, bridge construction, etc., can solve problems such as unfavorable stress states of bridge structures, and achieve the effects of avoiding diseases, reducing impact effects, and improving integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific examples are given in conjunction with the accompanying drawings to describe in detail as follows, but the present invention is not limited thereto.

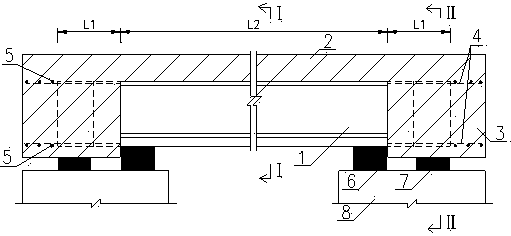

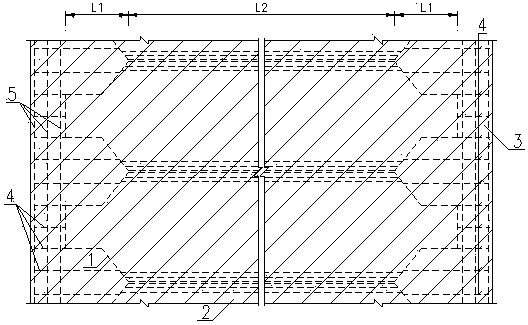

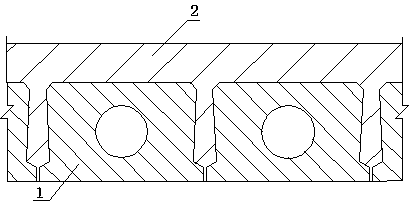

[0027] reference Figure 1 to Figure 4 , A hollow slab bridge structure with end cross beams, comprising prefabricated hollow slab 1, end cross beam 3 and cast-in-place structural layer 2. The prefabricated hollow slab is supported on temporary supports 6 on the tops of two adjacent abutments, or supports On the temporary support 6 on the top of two adjacent bridge piers, or supported on the temporary support 6 on the top of two adjacent bridge abutments and piers, the abutment or the top of the bridge pier is also provided with the temporary support 6 along the outer side of the longitudinal bridge The permanent support 7 of the prefabricated hollow slab 1 is poured with end cross beams 3 sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com