Flexible hanging self-expanding operation platform

An operation platform and self-expanding technology, applied in the direction of building structure support, building structure support, building structure support scaffolding, etc., can solve the problems of many safety hazards, long construction period, and extended construction period, so as to shorten the construction period and reduce construction costs , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

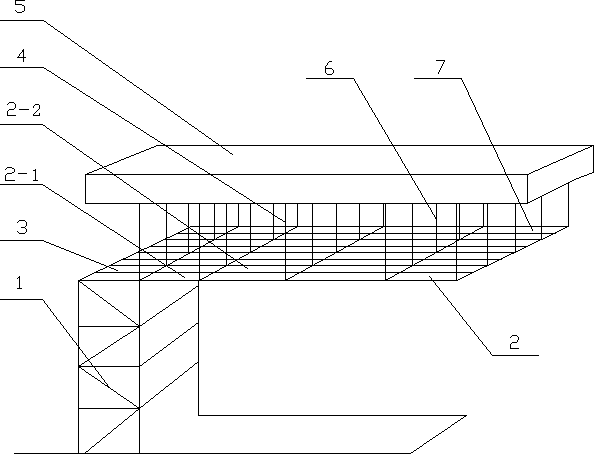

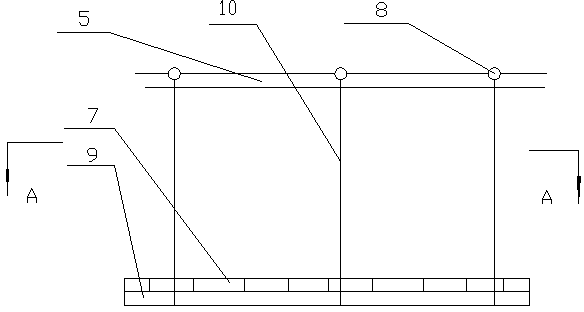

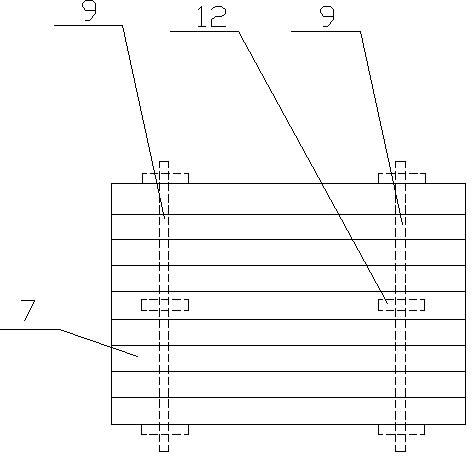

[0018] Such as figure 1 Shown in -4, the present invention comprises initial platform 1 and the expanded operation platform 2 that is positioned at initial platform 1 right side.

[0019] The initial platform 1 is a platform with a fastener type steel pipe scaffold structure, and a top plate 3 is arranged on the upper end of the initial platform.

[0020] There are multiple extended operating platforms 2, and the extended operating platforms 2 are units that expand outward from the initial platform 1 and have the same structure as each other. Adjacent extended operating platforms 2 are connected to each other; all extended operating platforms 2 Arranged in a row from left to right and from front to back, each row of extended operating platforms 2 includes a first extended operating platform 2-1, a second extended operating platform 2-1, and other extended operating platforms arranged in sequence from left to right. Operating platform 2; each extended operating platform 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com