A solenoid valve for ebs braking system

A braking system and solenoid valve technology, applied in the field of solenoid valves, can solve problems such as poor braking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

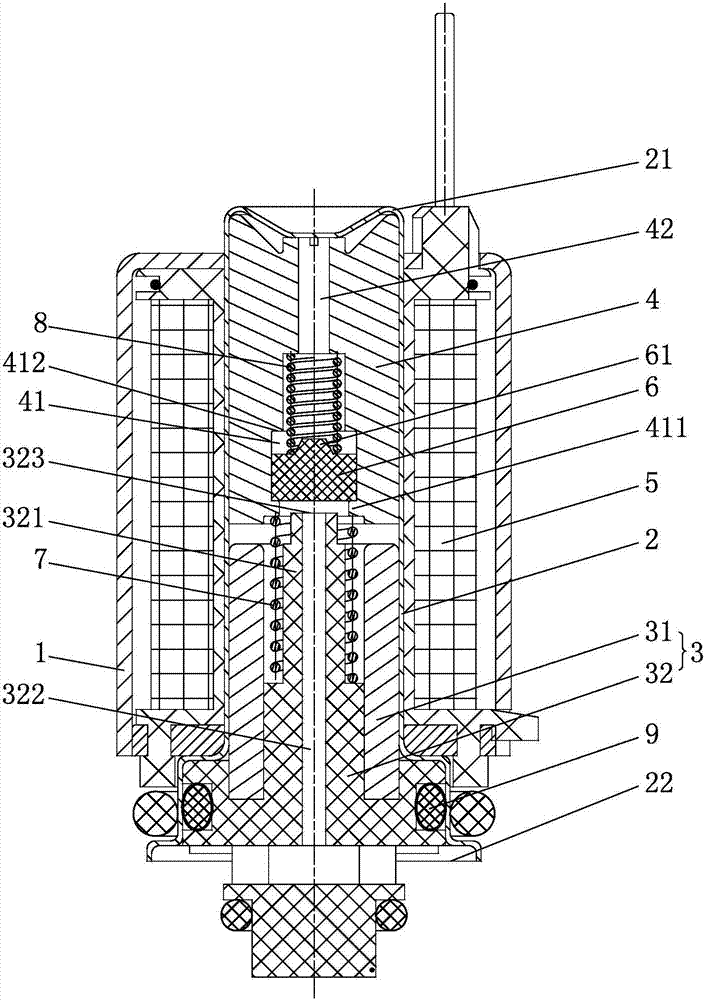

[0021] refer to figure 1 , a solenoid valve for EBS braking system, including a valve body 1, a sleeve 2 and an electromagnetic coil 5 wound on the sleeve 2 are arranged inside the valve body 1, and the top end of the sleeve 2 is provided with a direction to the sleeve 2 The positioning flange 21 extending in the axial direction, the bottom end of the sleeve 2 is provided with an assembly port 22, the sleeve 2 is provided with a static iron core assembly 3 and a moving iron core assembly, and the static iron core assembly 3 includes a fixed block 32 and a sleeve On the static iron core 31 on the fixed block 32, the fixed block 32 is provided with an air inlet passage and an air outlet passage 322, and the air inlet passage and the air outlet passage 322 are staggered mutually, and the moving iron core assembly includes the moving iron core 4 and the gasket 6, and the moving iron core assembly The iron core 4 is inserted into the sleeve 2 through the assembly opening 22 , and t...

Embodiment 2

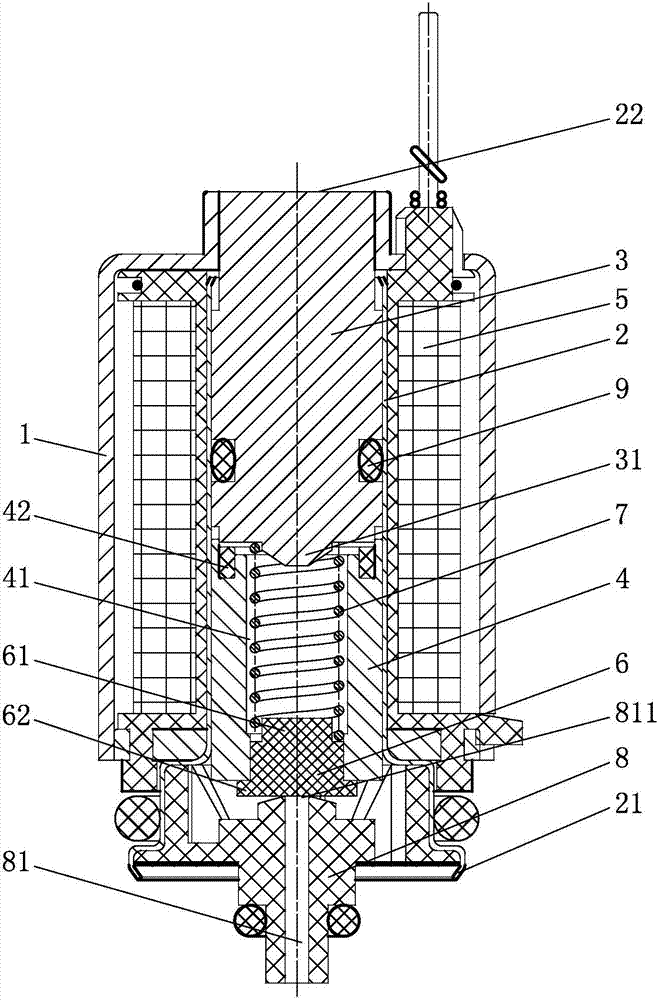

[0029] refer to figure 2 , a solenoid valve for EBS braking system, including a valve body 1, a sleeve 2 and an electromagnetic coil 5 wound on the sleeve 2 are arranged inside the valve body 1, and an assembly port 22 is arranged at the top of the sleeve 2, The bottom end of the sleeve 2 is provided with a positioning flange 21 extending toward the axial direction of the sleeve 2, and the sleeve 2 is provided with a static iron core assembly, a moving iron core assembly and a limit block 8, and the limit block 8 is provided with The air outlet channel and the air inlet channel 81, the gas outlet of the air inlet channel 81 located on the top surface of the limit block 8 is the valve port 811, the air outlet channel and the air inlet channel 81 are mutually staggered, the static iron core assembly includes the static iron core 3, the moving iron The core assembly includes a moving iron core 4 and a gasket 6 arranged at the bottom of the moving iron core 4 . The limit block 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com