Propylene compressor start-up dry sealing gas intake system

A technology of dry gas sealing and air intake system, which is applied in pipeline system, mechanical equipment, gas/liquid distribution and storage, etc. It can solve the problems of loss of propylene gas, high pressure, and nitrogen gas ingress, so as to reduce waste and avoid emptying , cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

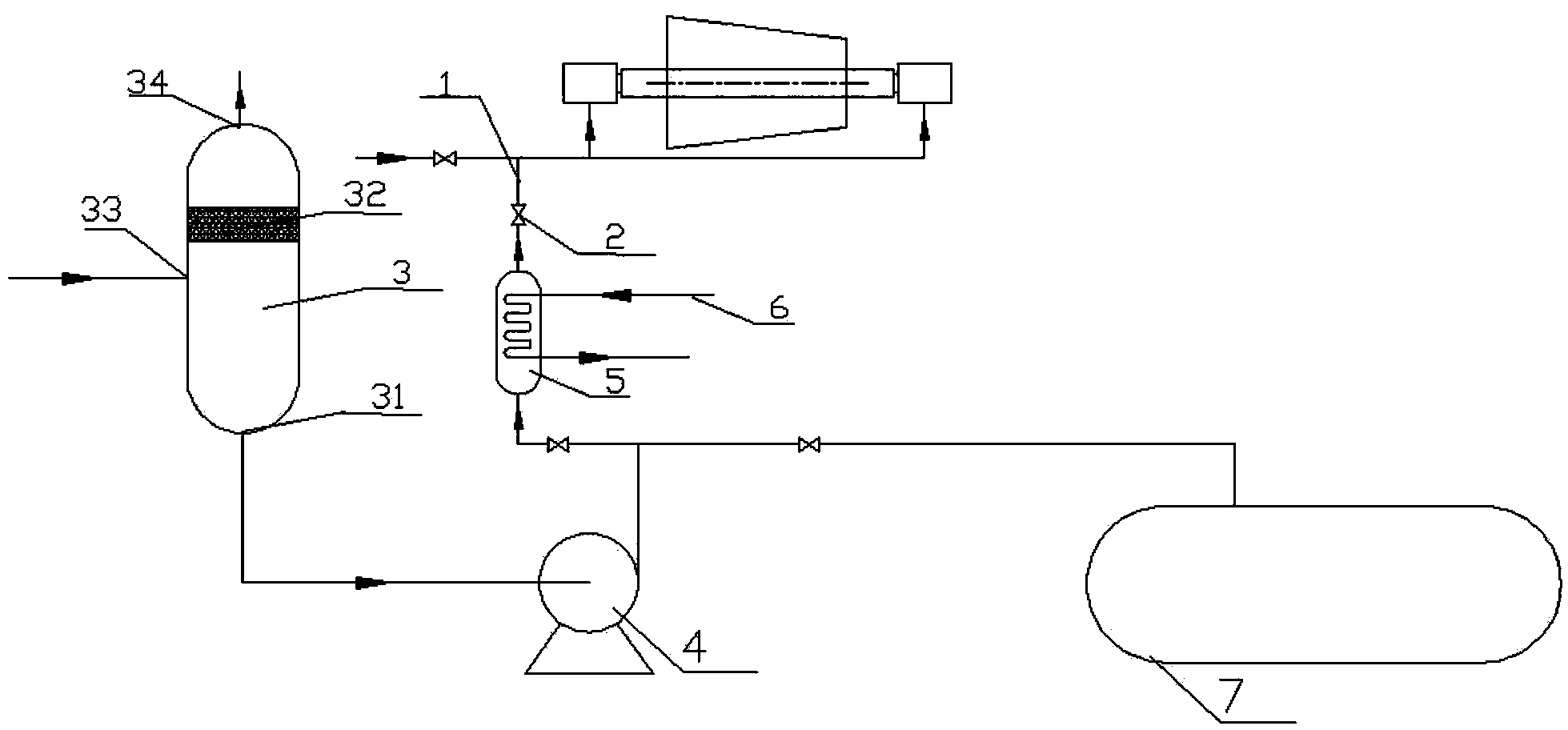

[0012] Such as figure 1 As shown, the propylene compressor start-up dry gas sealing gas intake system of the present invention consists of a propylene compressor start-up dry gas seal gas intake pipe 1, a propylene compressor start-up dry gas seal intake valve 2, a propylene separator 3, and a propylene liquid pump 4. It is composed of propylene vaporizer 5, propylene storage tank 7 and other components.

[0013] The structure of the propylene compressor is prior art, and its dry gas sealing system is also prior art, and will not be repeated here. Propylene compressor start-up dry gas sealing inlet valve 2 is set on the propylene compressor start-up dry gas sealing gas inlet pipe 1. When the propylene compressor starts up, it uses external propylene gas for sealing. After starting up, it is switched to unit outlet gas for sealing. .

[0014] The propylene separator 3 is provided with wire mesh packing 32, the bottom of the wire mesh packing 32 of the propylene separator 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com