A kind of LED high-power lamp and its application in greenhouse

A high-power, greenhouse technology, applied in greenhouse cultivation, components of lighting devices, semiconductor devices of light-emitting elements, etc., to achieve good lighting functions, promote photosynthesis, and solve heat dissipation problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

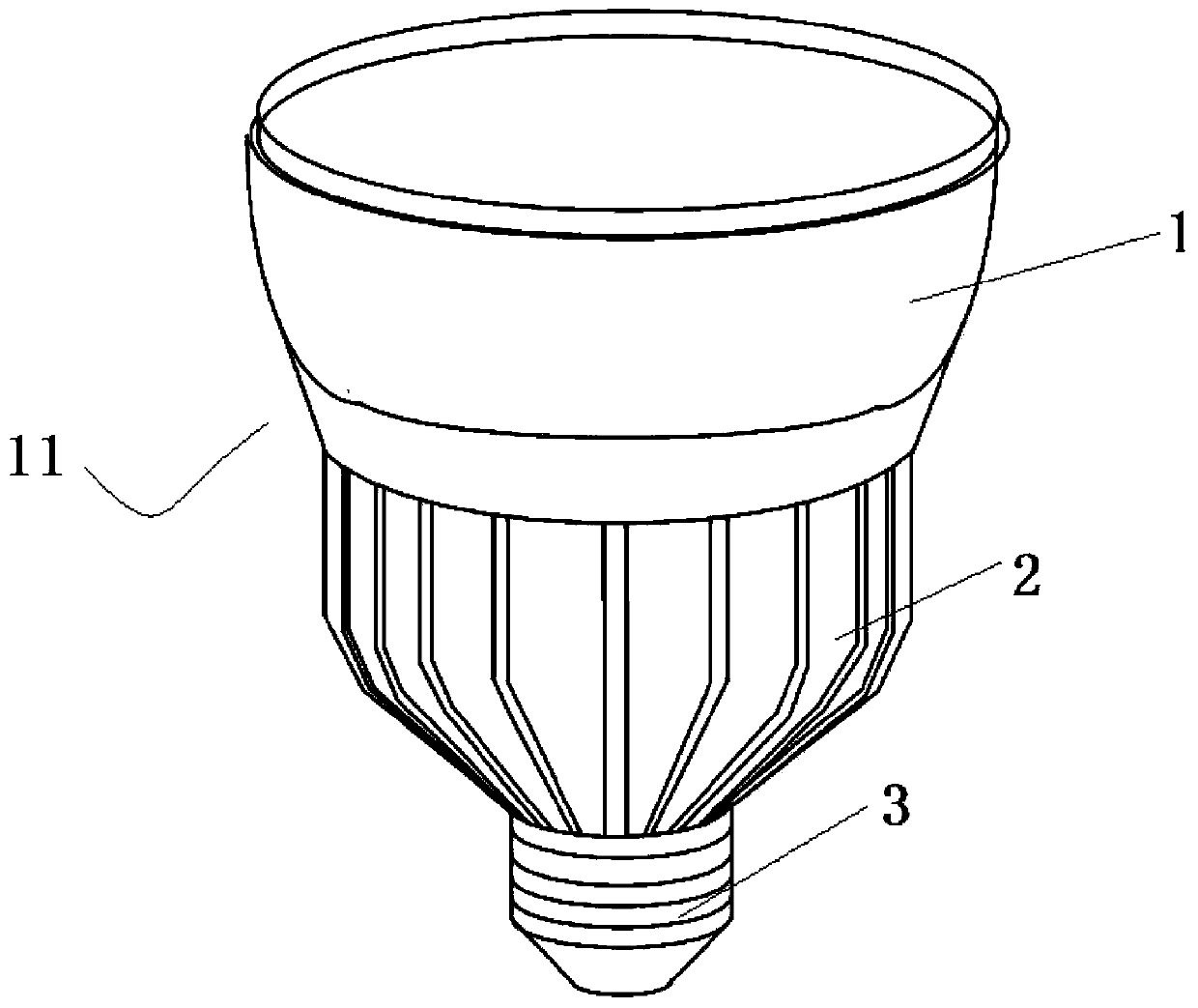

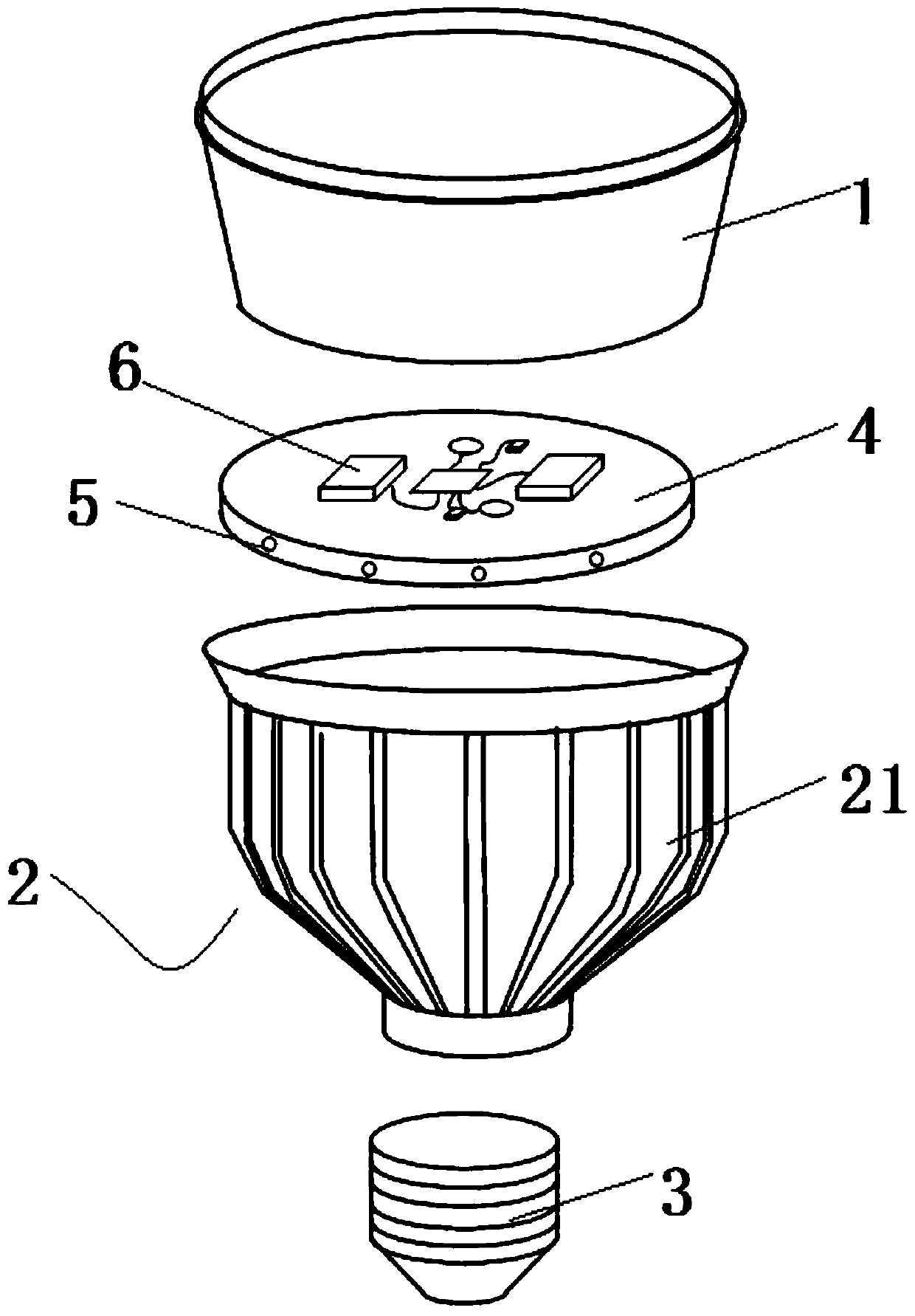

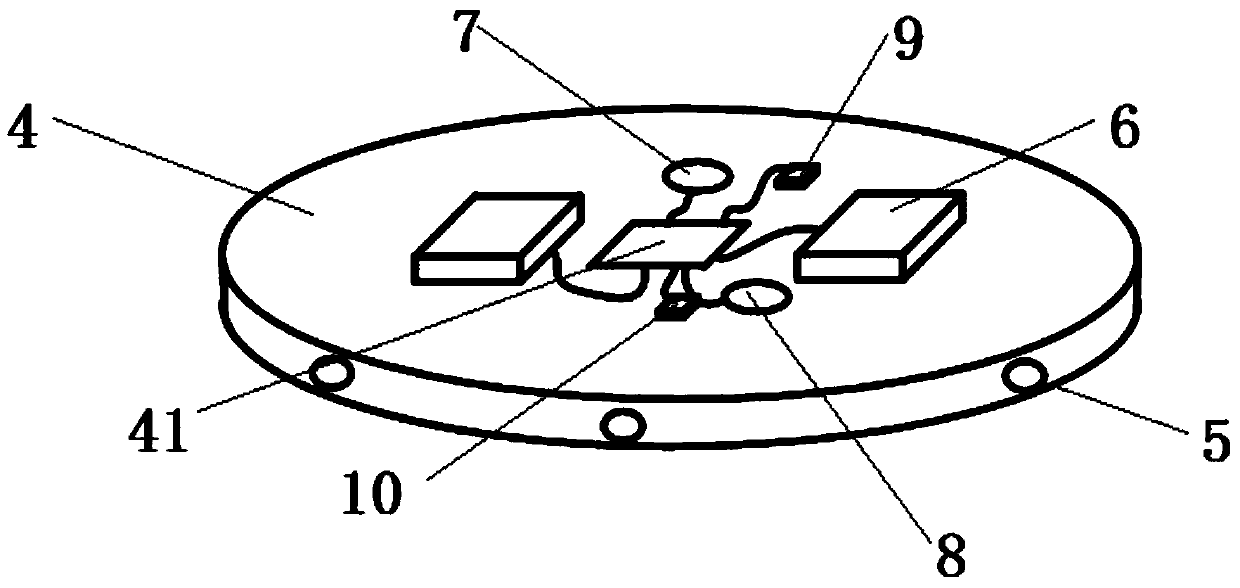

[0023] Embodiment 1: as Figures 1 to 3 As shown, the LED high-power lamp described in Embodiment 1 includes an installation part 3, a radiator 2 is arranged on the installation part 3, a lampshade 1 is arranged on the radiator 2, and the installation part 3 is provided externally. A threaded hollow cylinder, the radiator 2 is composed of a plurality of cooling fins 21, the large ends of the cooling fins 21 are connected with the substrate 4, and the smaller ends are connected with the mounting part 3, and the radiator 2 is also provided with The substrate 4 is provided with at least one heat dissipation channel 5 penetrating the substrate 4. The substrate 4 is also provided with at least two LED chips 6. The LED crystal grains in the LED chips 6 are mounted on the substrate with a temperature sensor and a control panel. LED on-off control circuit, the substrate 4 is provided with a control mainboard 41 connected to the temperature sensor and the LED chip internal control circ...

Embodiment 2

[0025] Embodiment 2: as Figures 1 to 4 As shown, an application device equipped with LED high-power lamps described in Embodiment 2 includes at least one LED lamp 11 described in Embodiment 1. The LED lamp 11 is arranged on a rotating wheel 12, and the rotating wheel 12 It is connected to the support frame 16 through the rotating shaft 13 , and the rotating shaft 13 is connected with the motor 15 through the transmission device 14 . In the greenhouse, the LED lights 11 are installed on the rotating wheel 12 rotated by the motor 15, so that the plants in the greenhouse can be illuminated in all directions and from multiple angles, thereby better promoting the photosynthesis of the plants.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com