Method and device for manufacturing pipeline crack defects

A manufacturing method and pipeline technology, applied in the preparation of test samples, etc., can solve the problems of inaccurate manufacturing of pipeline crack defects, achieve the effect of accurate position and size, meet technical requirements, and ensure position and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Embodiments of the present invention provide a method and device for manufacturing pipeline crack defects to solve the technical problem of inaccurate manufacturing of pipeline crack defects in the prior art.

[0043] The technical solution in the embodiment of the present application is to solve the above-mentioned technical problems, and the general idea is as follows:

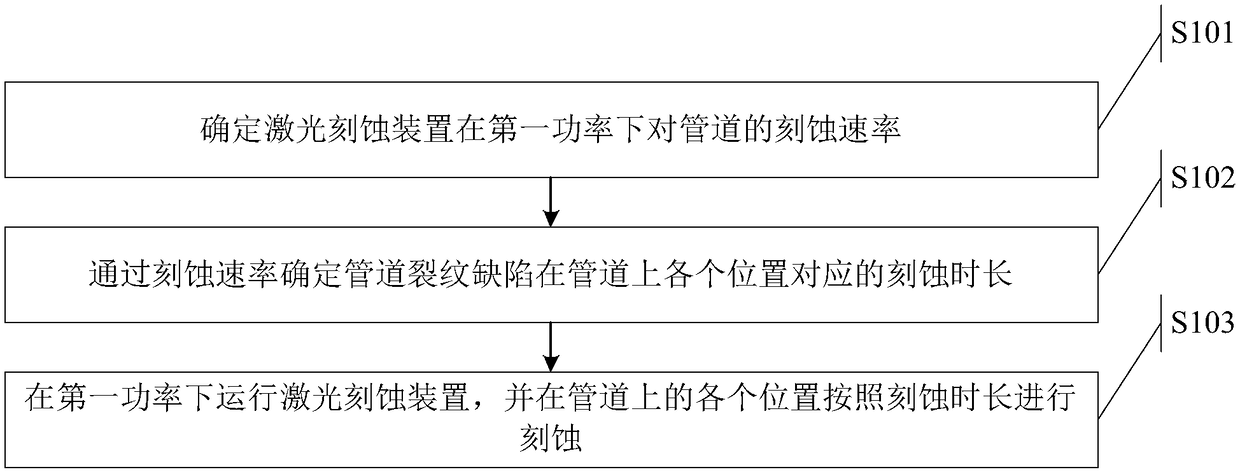

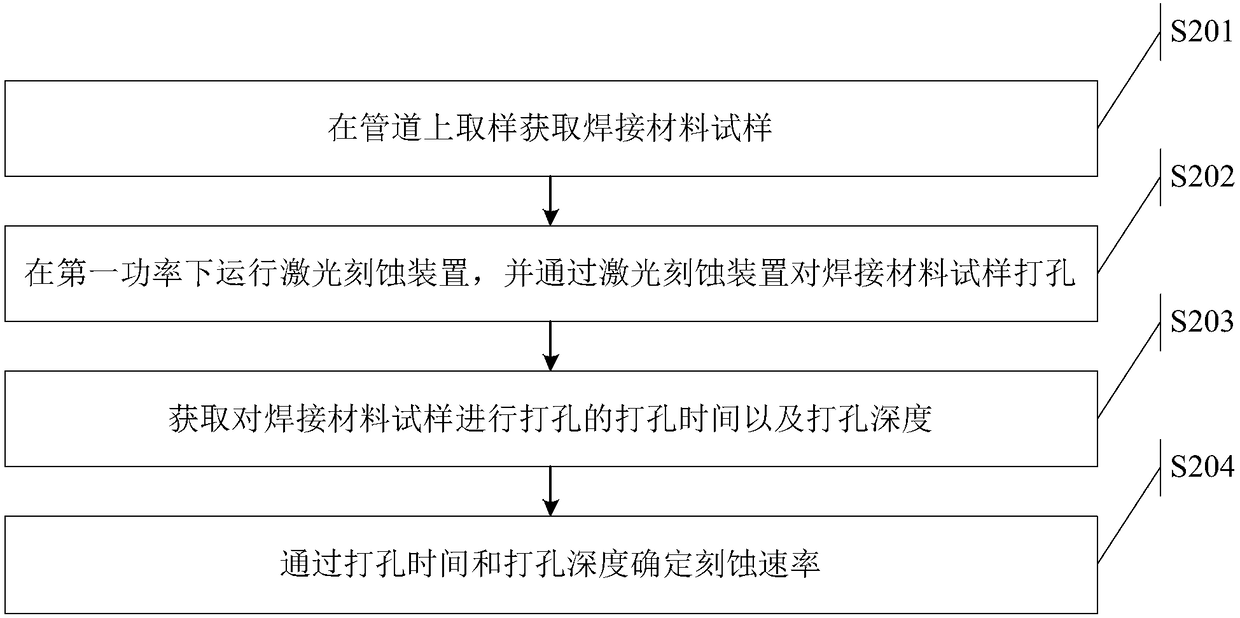

[0044] A method for manufacturing pipeline crack defects is provided, including: determining the etching rate of the pipeline by a laser etching device under the first power; determining the etching time corresponding to each position of the pipeline crack defect on the pipeline through the etching rate; Operate the laser etching device at a certain power, and etch at various positions on the pipeline according to the etching time. That is to say, a reasonable position of the crack defect in the welding material is designed, and the size is also controlled more precisely. In addition, the laser etchin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com