Shape and particle size measuring method for tar residue

A measuring method and technology of tar residue, which are applied in the directions of measuring device, particle size analysis, particle and sedimentation analysis, etc., can solve the problems of tar residue shape and particle size measurement difficulties, etc., and achieve the effect of avoiding the entry of inferior raw materials and ensuring stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

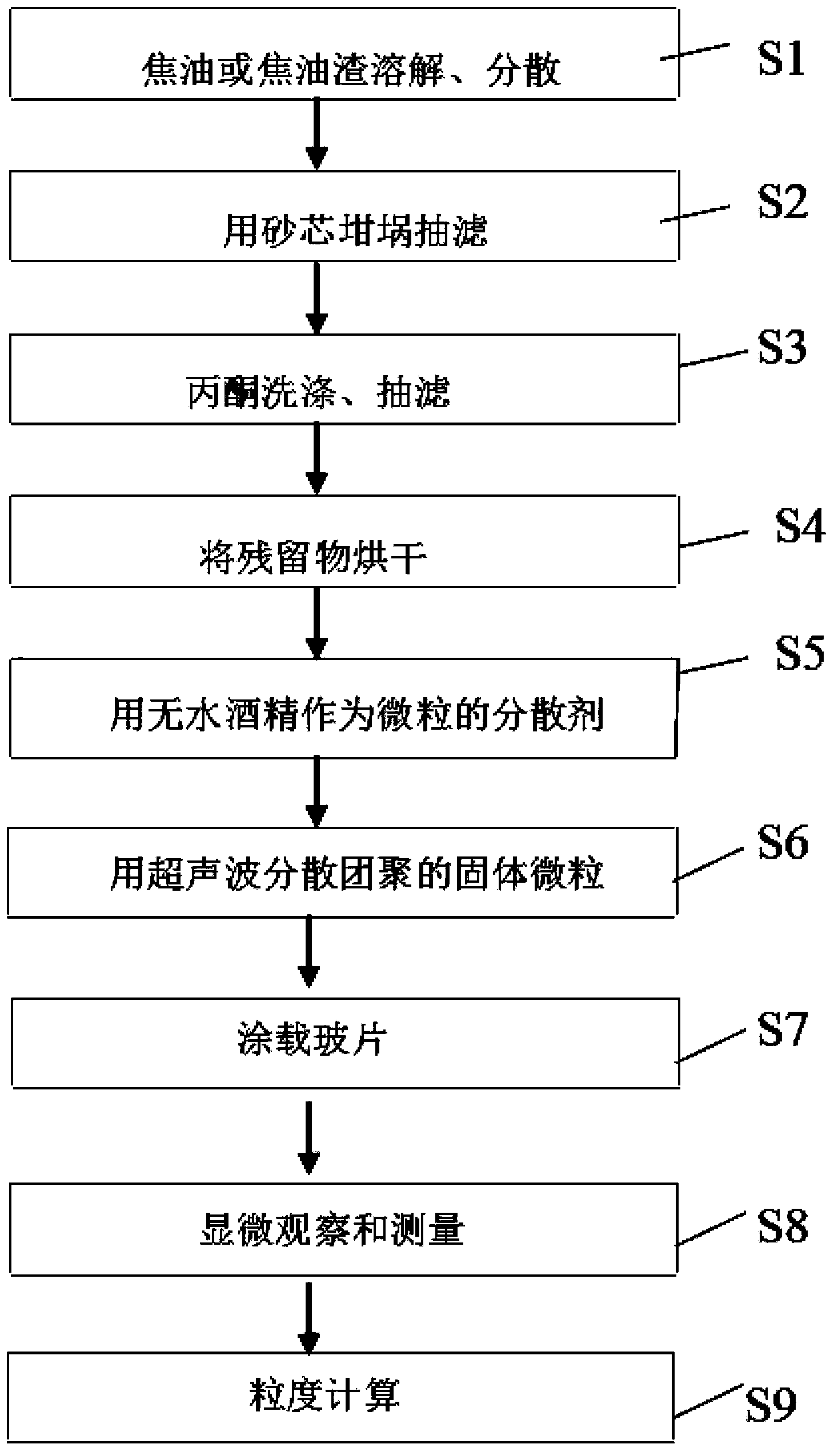

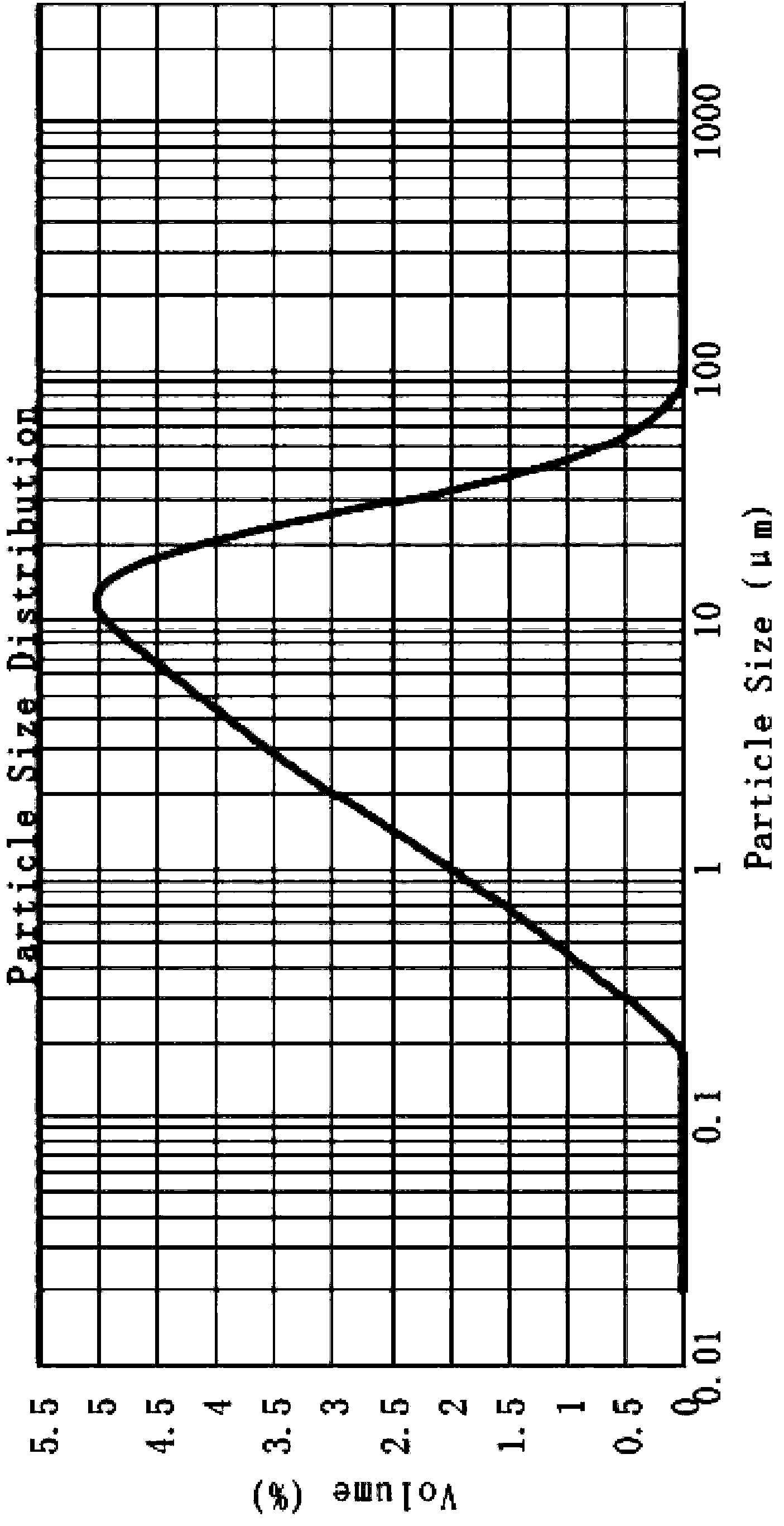

[0034] Take some tar, dissolve it in hot quinoline at 80°C, stir and disperse it with 40KHz ultrasonic waves for 3 minutes; use a 4# sand core crucible while it is hot, filter it under vacuum, and then filter it three times with hot quinoline; Wash and filter 5 times; dry the sand core crucible with residue in an oven at 105°C to obtain solid particles (QI) in tar; take a small amount of dry powder obtained by suction filtration and place it in a clean container , add 2mL of absolute alcohol as a dispersant; disperse the agglomerated solid particles with 40KHz ultrasonic waves for 2 minutes, until the particles are invisible to the naked eye, and appear black and turbid; evenly apply the suspension containing solid particles on a glass slide, and wait for the alcohol to naturally Volatile; observe and measure under a reflection microscope, and take pictures at a certain magnification (200×). The particle size distribution was calculated using analytical software.

Embodiment 2

[0036] Take some tar residue, dissolve it in hot pyridine at 70°C, stir and disperse it with 40KHz ultrasonic wave for 5 minutes; use a G4 sand core crucible while it is hot, filter it under vacuum, and then filter it with hot quinoline for 5 times; wash it with acetone Suction filtration 3 times; dry the sand core crucible with residue in an oven at 150°C to obtain solid particles in tar; take a small amount of dry powder obtained by suction filtration, put it in a clean container, add 1 mL of Water alcohol as a dispersant; use 40KHz ultrasonic waves to disperse the agglomerated solid particles for 4 minutes until the particles are invisible to the naked eye and appear black and turbid; apply the suspension containing solid particles evenly on a glass slide, and dry the alcohol; Observe and measure under a microscope, and take photos at a certain magnification (500×). The particle size distribution was calculated using analytical software.

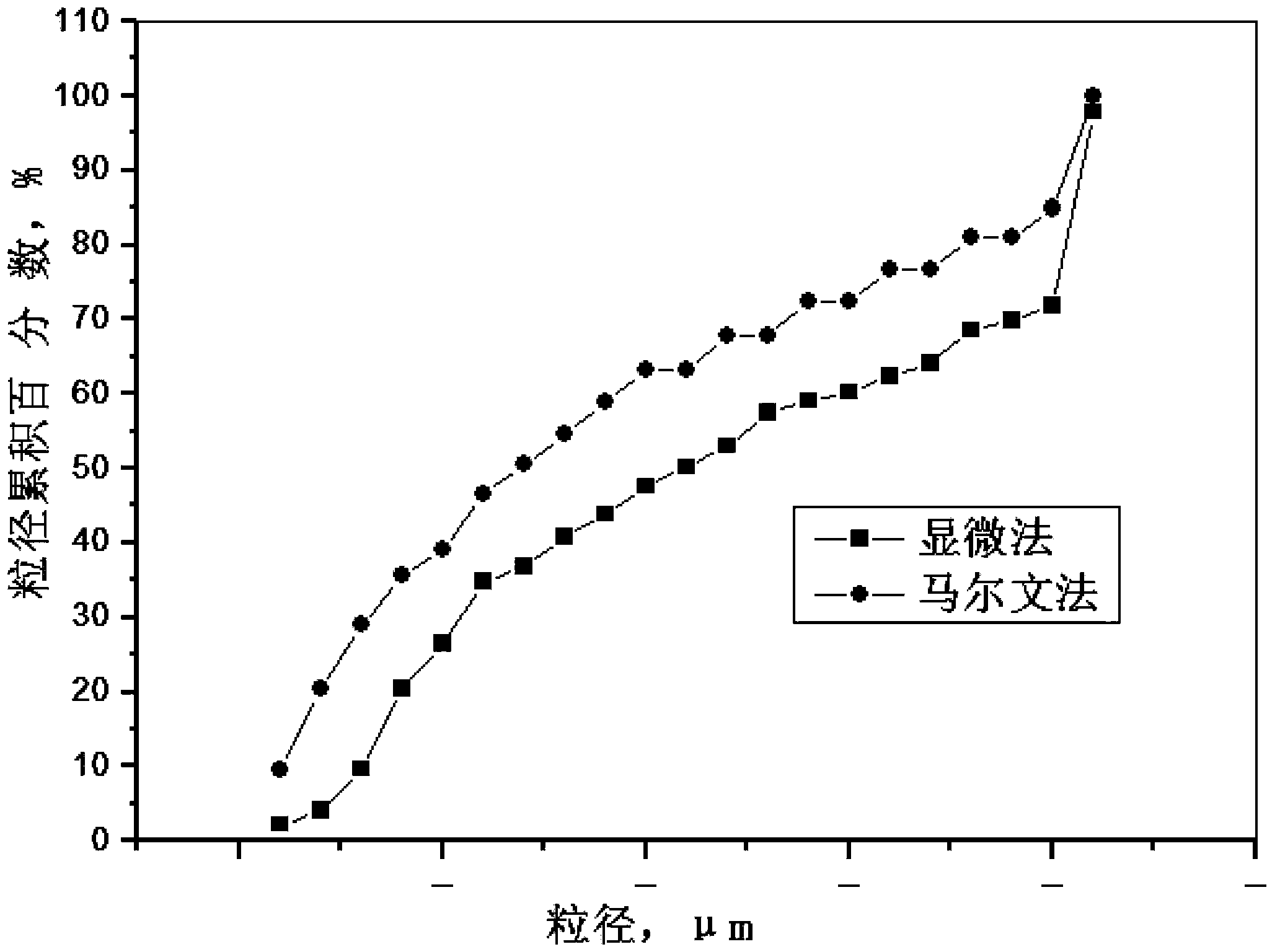

[0037] The particle aggregate str...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap