Odor evaluation method for automotive interior parts

A technology for car interiors and evaluation methods, applied in the field of air quality control in automobiles, can solve the problems of complex material composition of parts, difficulty in checking the source of vehicle odor, and poor material uniformity of car interior parts, etc. The effect of preventing missed detection problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further explain the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings.

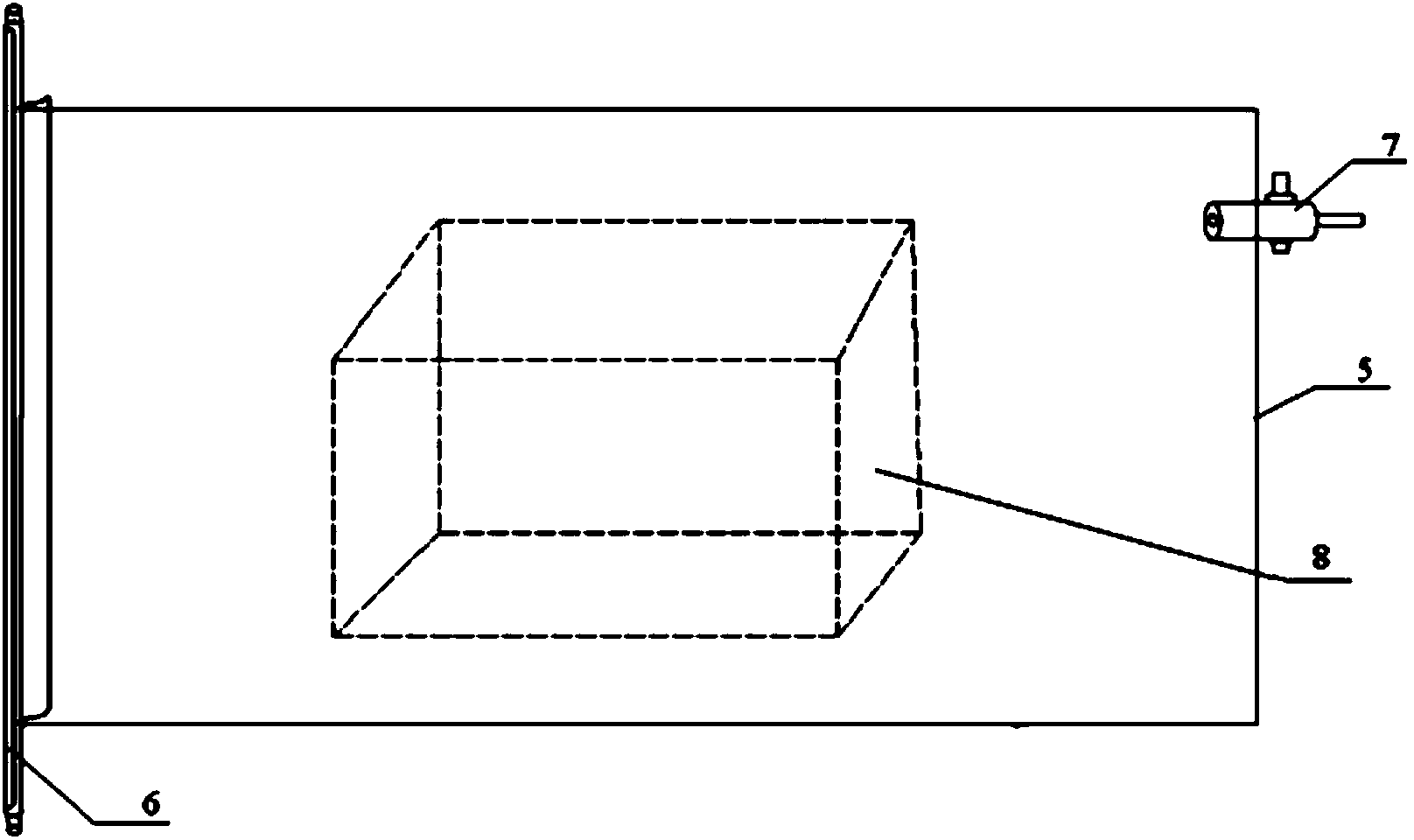

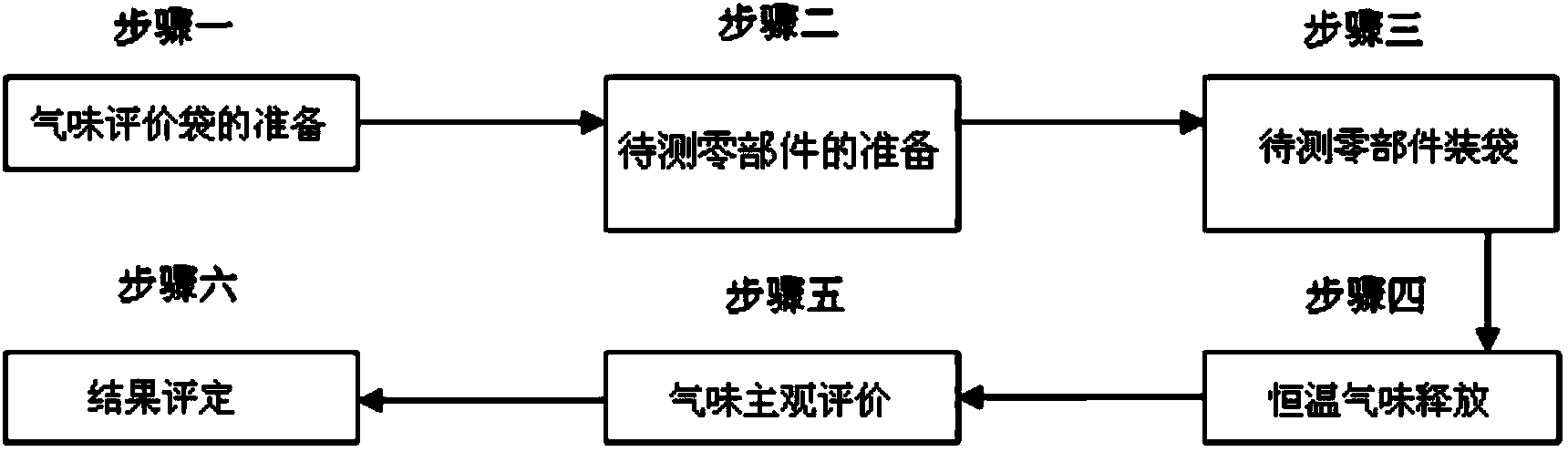

[0036] see figure 1 and figure 2 As shown, the odor evaluation method of automotive interior parts includes the following steps:

[0037] Step 1. Preparation of odor evaluation bag

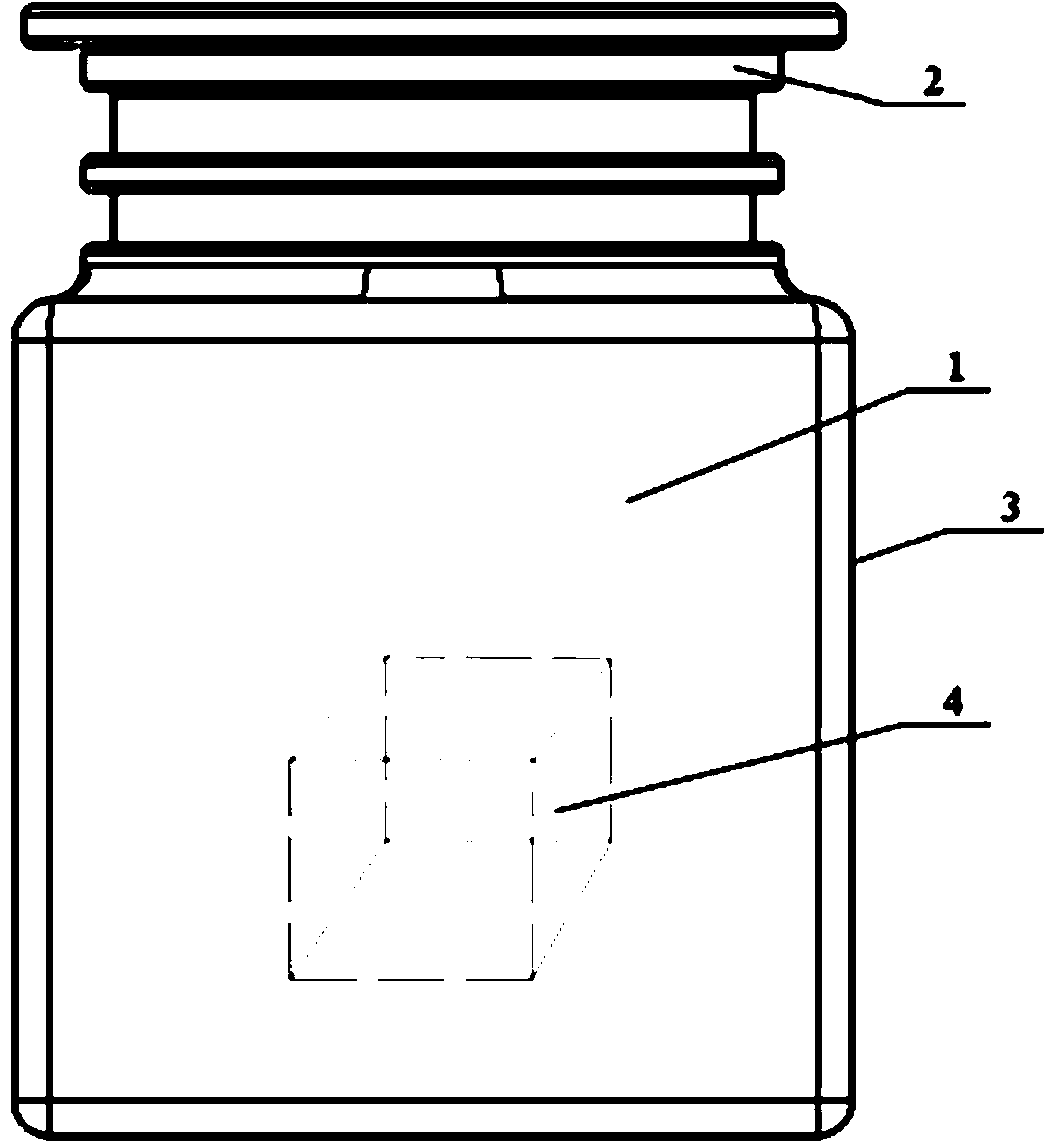

[0038] 1. The odor evaluation bag 5 has only one end opening, and the opening is sealed by a sealing strip 6, and an inflatable switch 7 is arranged on the odor evaluation bag, and the odor evaluation bag 5, the sealing strip 6 and the inflatable switch 7 are all made of polytetrafluoroethylene Made to meet the requirements of the material having no peculiar smell and being able to withstand temperatures above 150°C.

[0039] ② Check the airtightness of the odor evaluation bag 5 by vacuuming to ensure that the airtightness of the odor evaluation bag 5 is good.

[0040] ③Before use, the odor evaluation bag ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com