Double-core butterfly optical cable production technology

A butterfly optical cable and production process technology, applied in the field of optical cable production process, can solve the problems of optical fiber influence, optical fiber communication interruption, etc., achieve the effect of convenient and efficient production, and reduce the probability of abnormality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the purpose, technical solution and advantages of the present invention clearer, the technical solution of the present invention will be clearly and completely described below in conjunction with specific embodiments of the present invention and corresponding drawings.

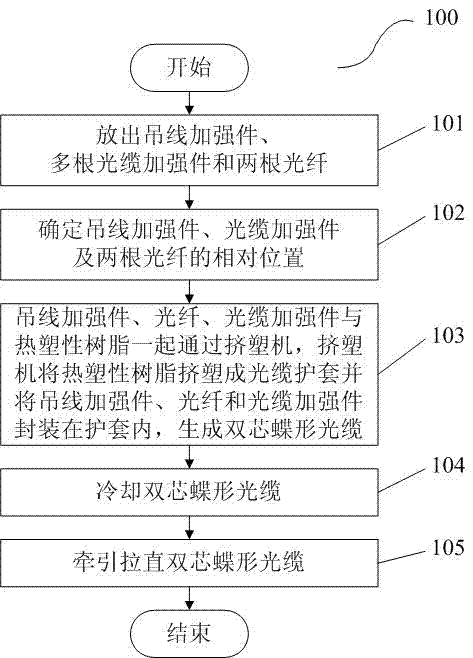

[0022] refer to figure 1 , figure 1 Shown is a process schematic diagram of an embodiment of a double-core butterfly cable production process of the present invention. In this embodiment, the production process of the double-core butterfly cable includes steps 101-105:

[0023] In step 101, a suspension wire strength member, a plurality of fiber optic cable strength members and two optical fibers are paid out.

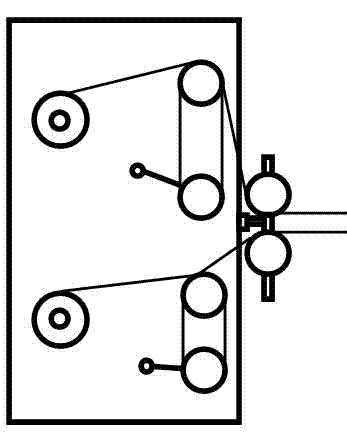

[0024] In one embodiment of the present invention, as figure 2 as shown, figure 2 It is a kind of active pay-off structure adopted for the hanging wire reinforcement or optical cable reinforcement of the present invention. The suspension wire reinforcement or optical cab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com