Parameter error accumulation based gear system performance reliability degree calculation method

A gear system and error accumulation technology, which is applied in calculation, electrical digital data processing, special data processing applications, etc., can solve the problem of not comprehensively considering the calculation method of gear center distance deviation performance reliability, so as to reduce the number of simulations and improve calculation Efficiency, the effect of ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

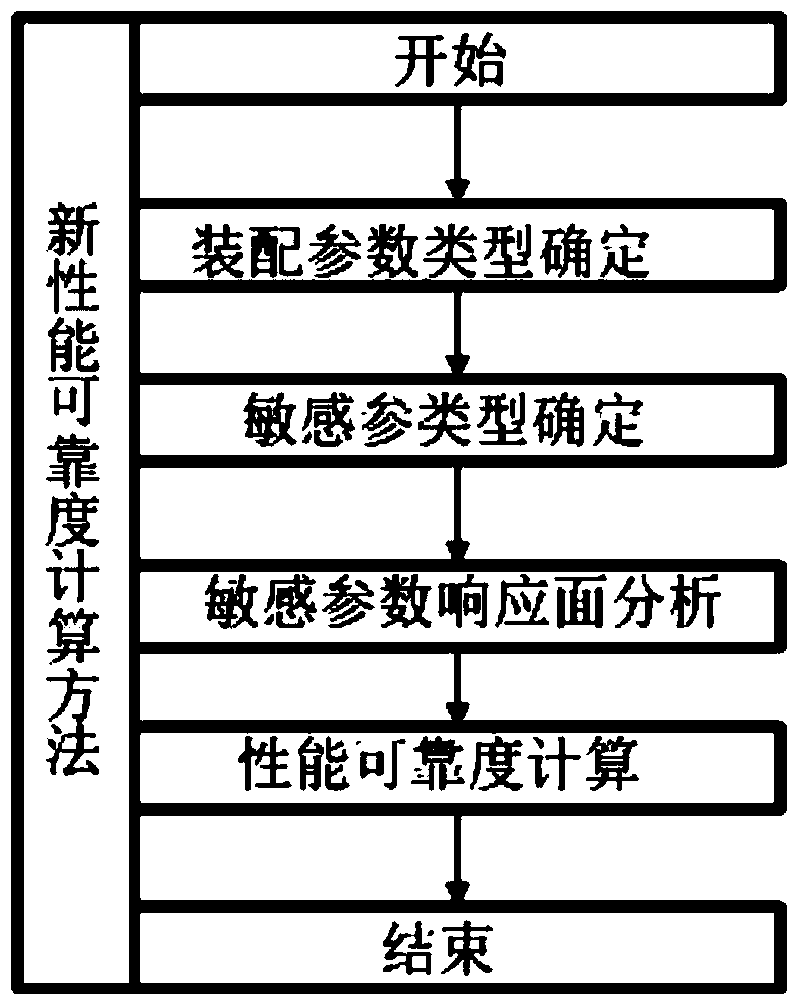

[0038] The present invention is a gear system performance reliability calculation method based on parameter error accumulation, see figure 1 As shown, the specific steps of the method are as follows:

[0039] Step 1: Determination of assembly parameter type

[0040] Analyze the gear system to obtain the specific structural size information of the gear system. According to the tolerance and coordination manual, determine the type of parameters that have deviations during gear assembly, and determine the tolerance range of the parameters.

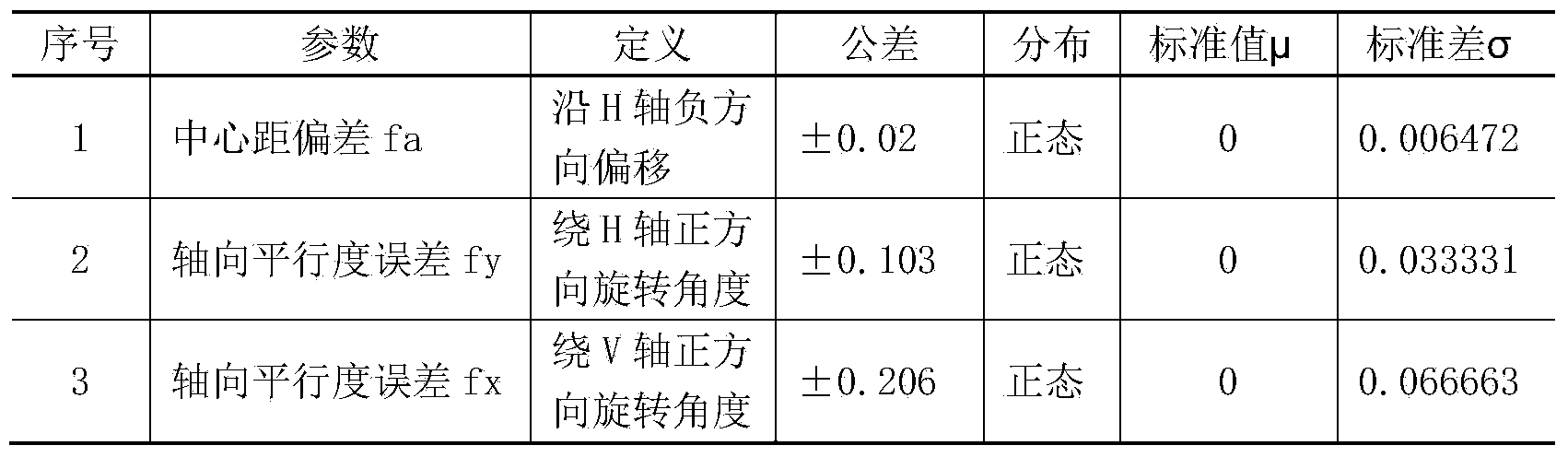

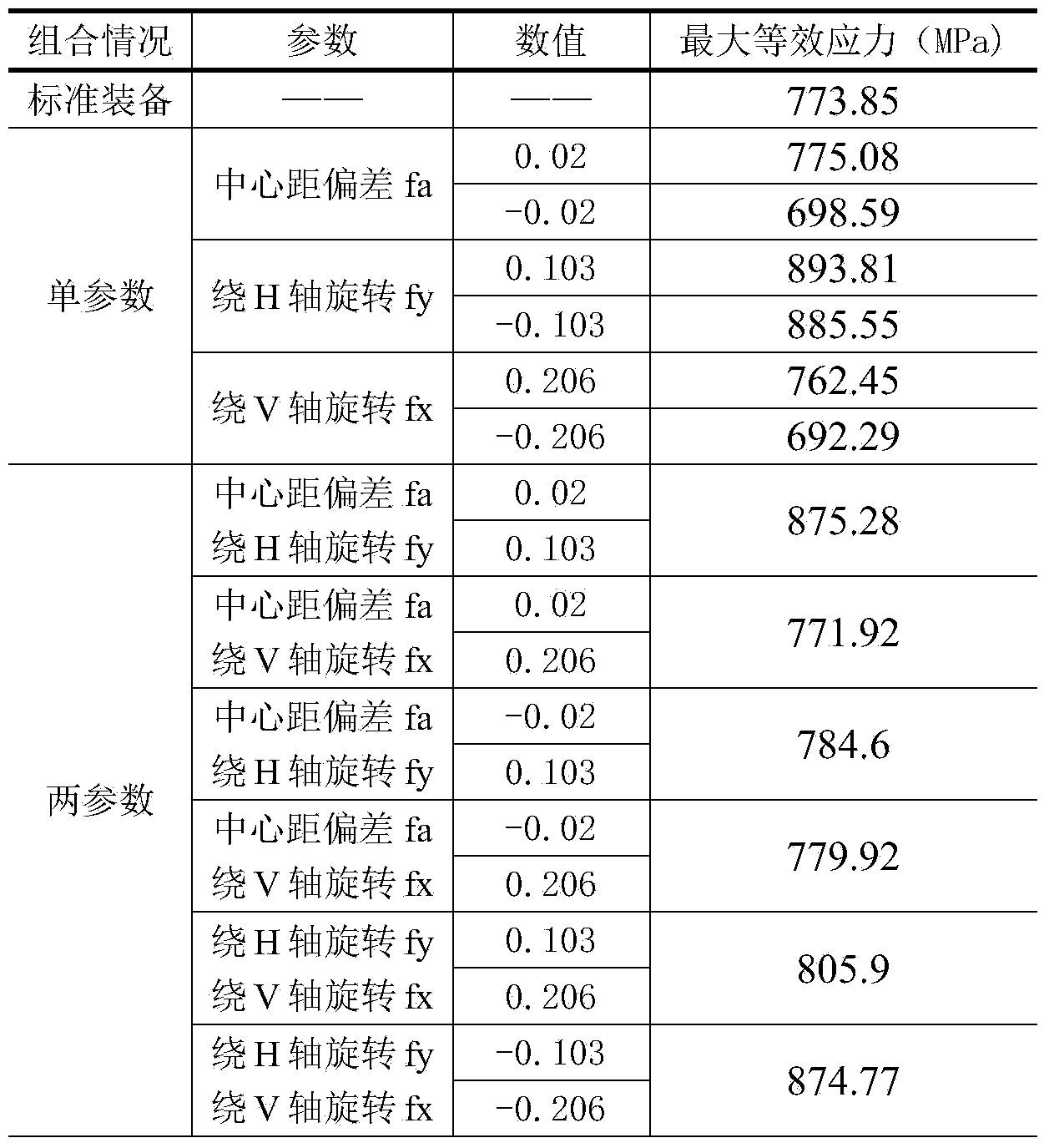

[0041] According to the physical and interchangeability analysis of the gear pair, the assembly deviation parameters of a pair of gears include gear center distance deviation and gear axis parallelism error. Combining the structural dimensions and assembly dimensions of the gear system, it is easy to find a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com