A digital acoustic equipment compatibility test platform based on motion control

A technology for compatibility testing and acoustic equipment, applied in mechanical equipment, underwater operation equipment, measuring devices, etc., can solve the problems of increasing the development cycle of underwater submersibles, occupying large design resources, and mutual interference, etc., to reduce design Time cost, data synchronization, less manual intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

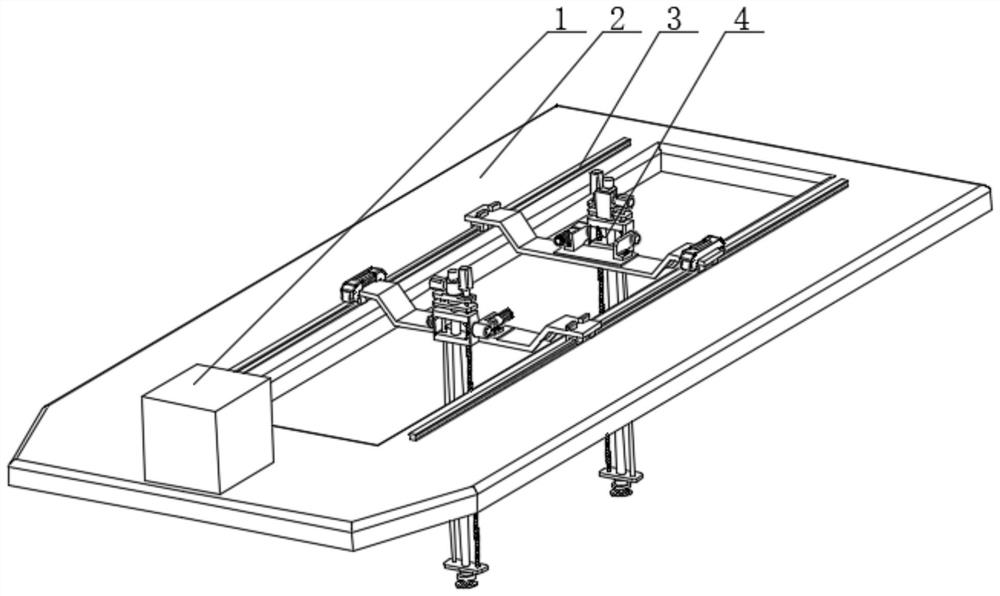

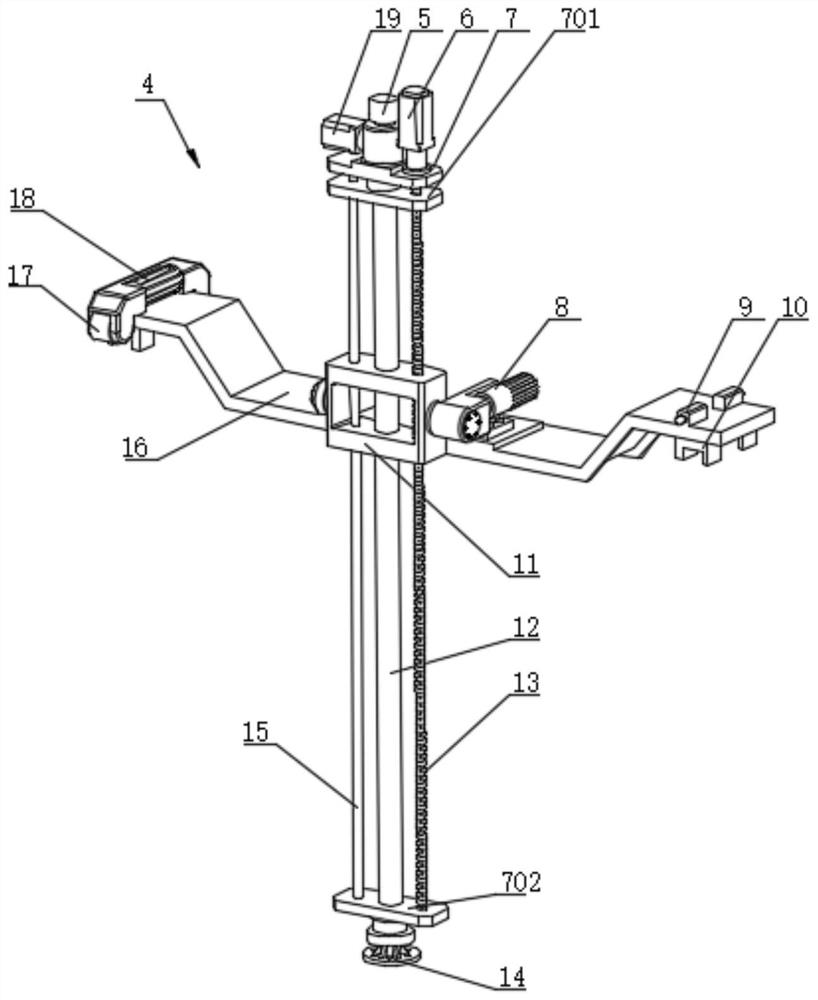

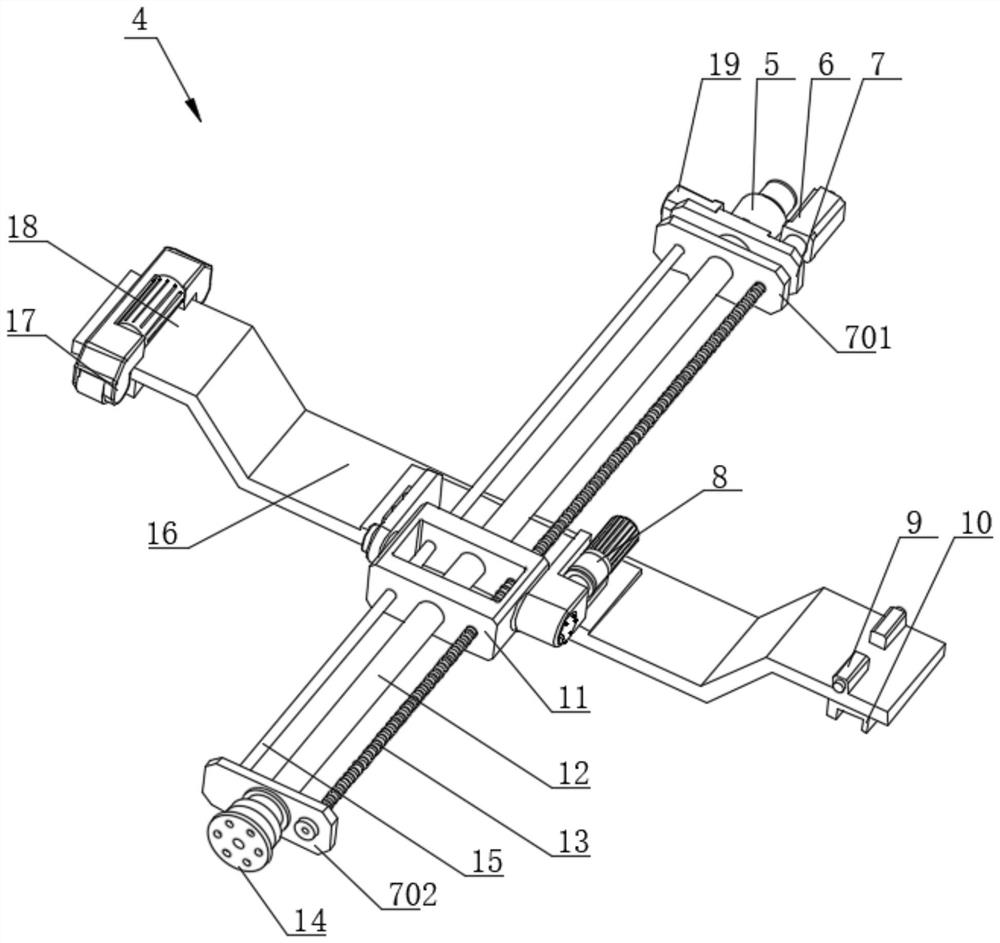

[0031] Such as figure 1 , figure 2 and image 3 As shown, the digital acoustic equipment compatibility test platform based on motion control of the present embodiment includes a platform deck 2, an electrical control box 1 is fixed on one end of the upper surface of the platform deck 2, and a hole is provided on the platform deck 2, and the two sides of the hole A guide rail 3 is provided, and a plurality of transducer hanging bracket assemblies 4 sliding along the guide rail 3 are installed inside the hole. The bottom of the fixed acoustic equipment.

[0032] The structure of the single transducer hanging bracket assembly 4 is as follows: comprising a bracket beam 16, the upper surface of the middle part of the bracket beam 16 is fixed with a bracket rotation drive motor 8, the output end of the bracket rotation drive motor 8 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com