Polysilicon fuse monitoring structure and monitoring method

A polysilicon fuse, fusing technology, applied in the direction of fuse testing, instruments, electrical components, etc., can solve problems such as inability to obtain other devices, inability to monitor polysilicon fuses, devices or circuits that cannot work normally, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

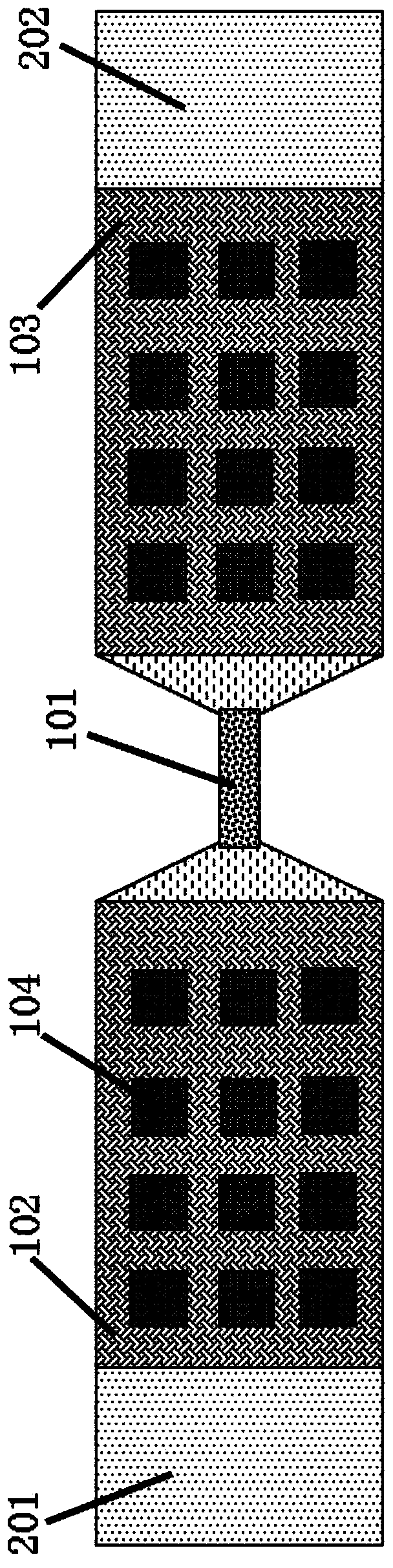

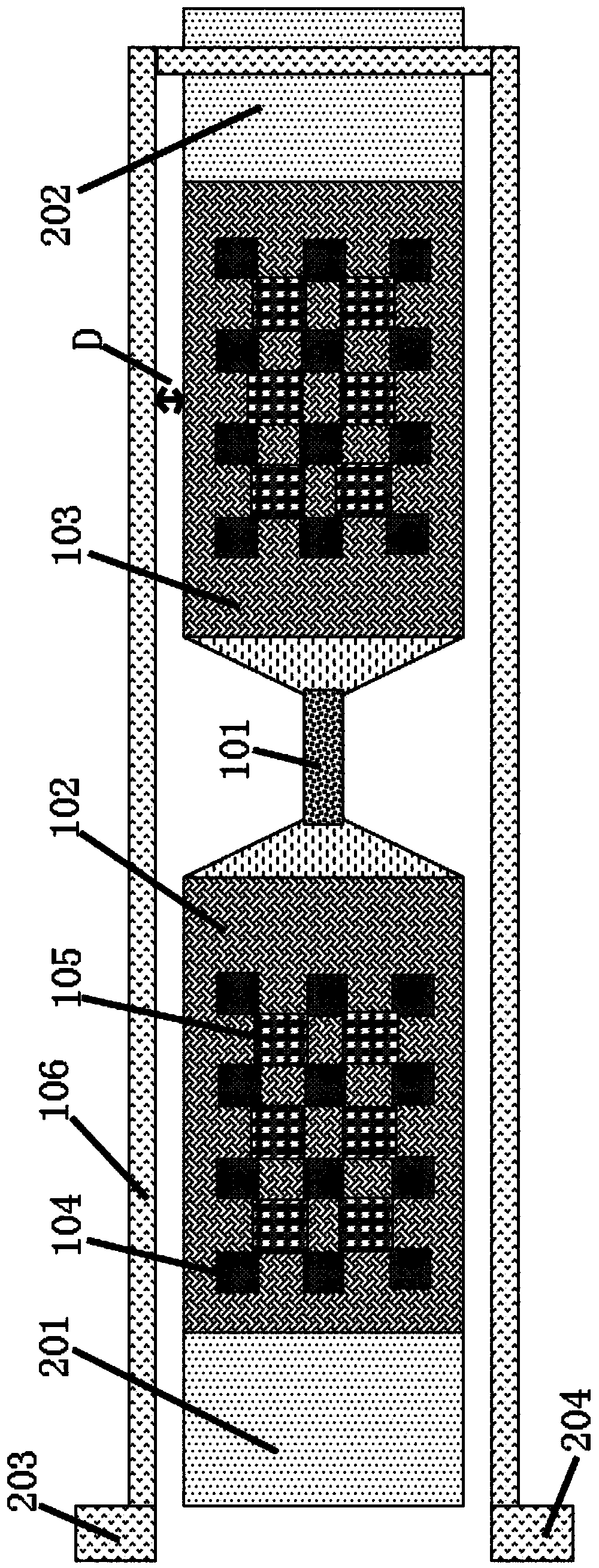

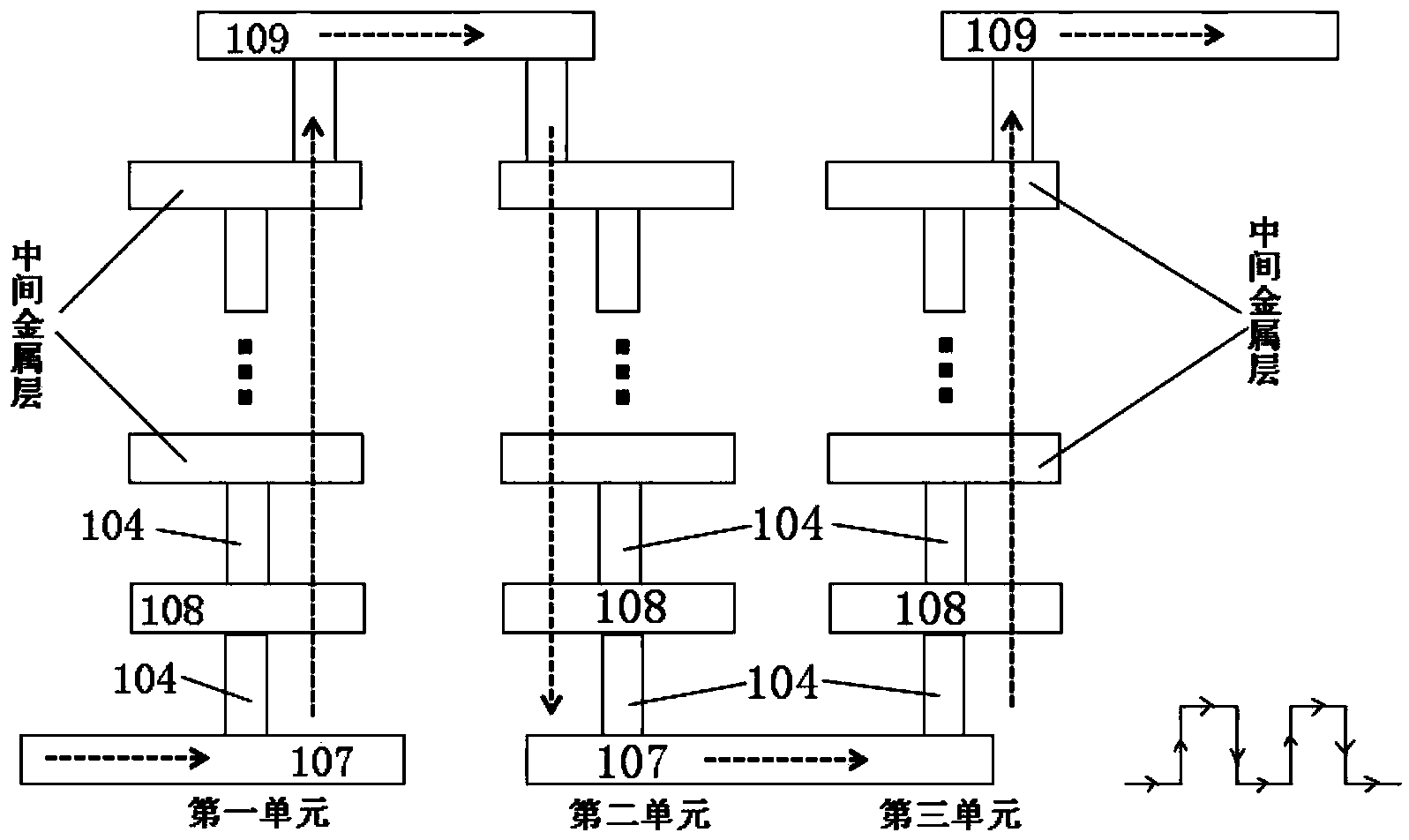

[0020] The polysilicon fuse monitoring structure described in the present invention is generally placed in the scribing groove area of the chip. like figure 2 As shown, it includes a polysilicon fuse 101 with a specific length and width (determined according to the actual demand of the product). The two ends of the polysilicon fuse 101 have a first lead-out area 102 and a second lead-out area 103. The first lead-out area 102 and the second lead-out area 103 The second lead-out area 103 is a multi-layer metal structure, and each layer of metal is connected by a through hole 104 and an interlayer connection hole 105; the first lead-out area 102 and the second lead-out area 103 also have a first test terminal 201 and a second Test terminal 202;

[0021] There is an unclosed conductive ring 106 around the polysilicon fuse 101 and the first and second lead-out areas at a certain distance D, and the two ports of the unclosed conductive ring 106 are the third test terminal 203 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com