device for securing a workpiece to be processed by means of a processing machine

A technology for processing machines and workpieces, applied in the field of workpiece devices, can solve the problems of cumbersome workpiece clamping, not ensuring that the workpiece position is fixed, etc., and achieves the effects of clamping the workpiece well, improving stable positioning, and reducing the weight of the device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

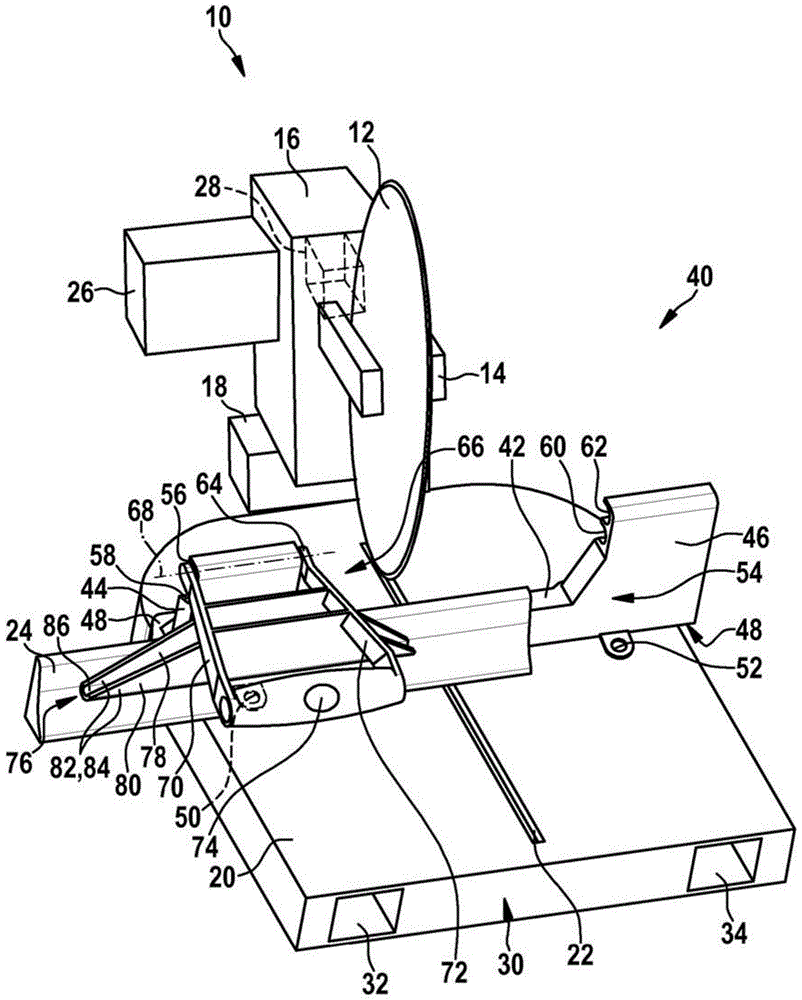

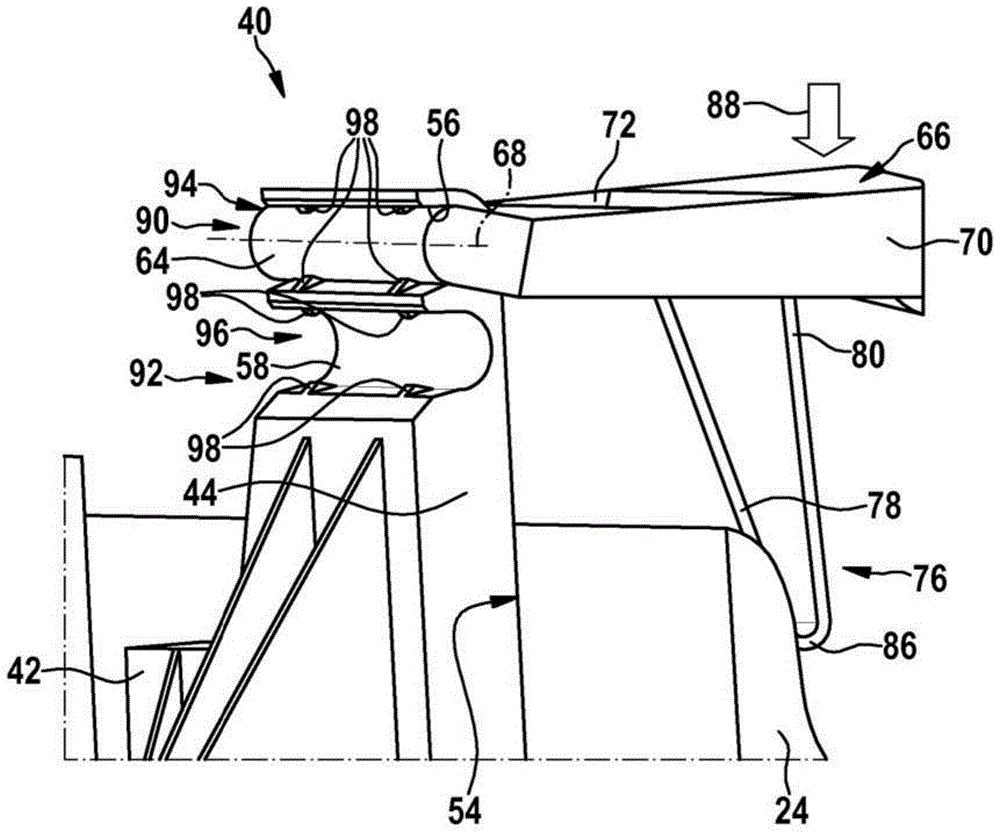

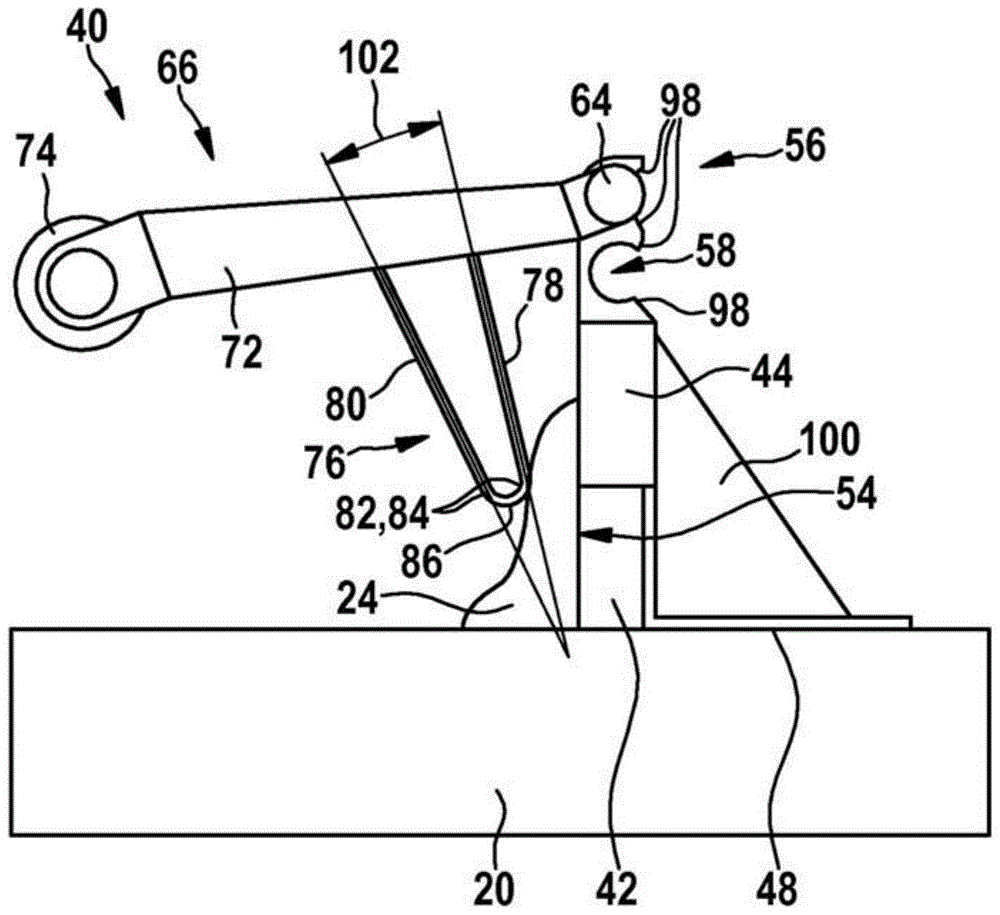

[0037] figure 1 A processing machine 10 , which is configured as an exemplary stationary saw device, is shown, which has, for example, a disc-shaped saw blade 12 , which is rotatably mounted in a fork 14 . In contrast thereto, the processing machine 10 can also be designed, for example, in the manner of a drilling and / or milling device.

[0038] The fork 14 is arranged on the illustrated square cylinder 16 , which is connected via a base 18 to a plate-shaped base 20 or workpiece support of the processing machine 10 . The base 18 enables the column 16 to tilt relative to the vertical so that the saw blade 12 can be lowered towards the base plate 20 for sawing. Furthermore, the fork 14 can be displaceable on the cylinder 16 in an axial direction parallel to its longitudinal center axis.

[0039] In the base plate 20 , below the saw blade 12 is provided an elongated slot 22 which at least partially receives said saw blade 12 when the column 16 is tilted or the fork 14 is lowere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com