Method and tool for drilling and marking of common machine tool

A machine tool and marking technology, applied in the field of signal plate processing, can solve problems such as processing difficulties, and achieve the effects of stable quality, high efficiency, fast and reliable clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with embodiment, the present invention is further described, but does not constitute any restriction to the present invention, anyone makes the limited number of amendments in the scope of claims of the present invention, still within the scope of claims of the present invention.

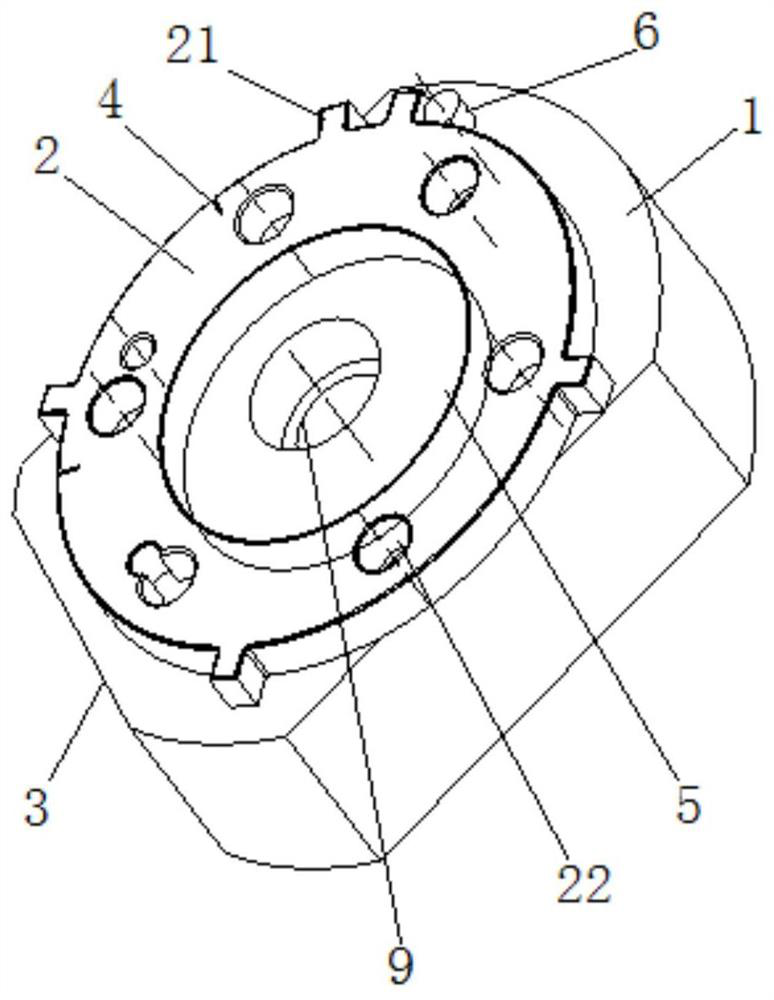

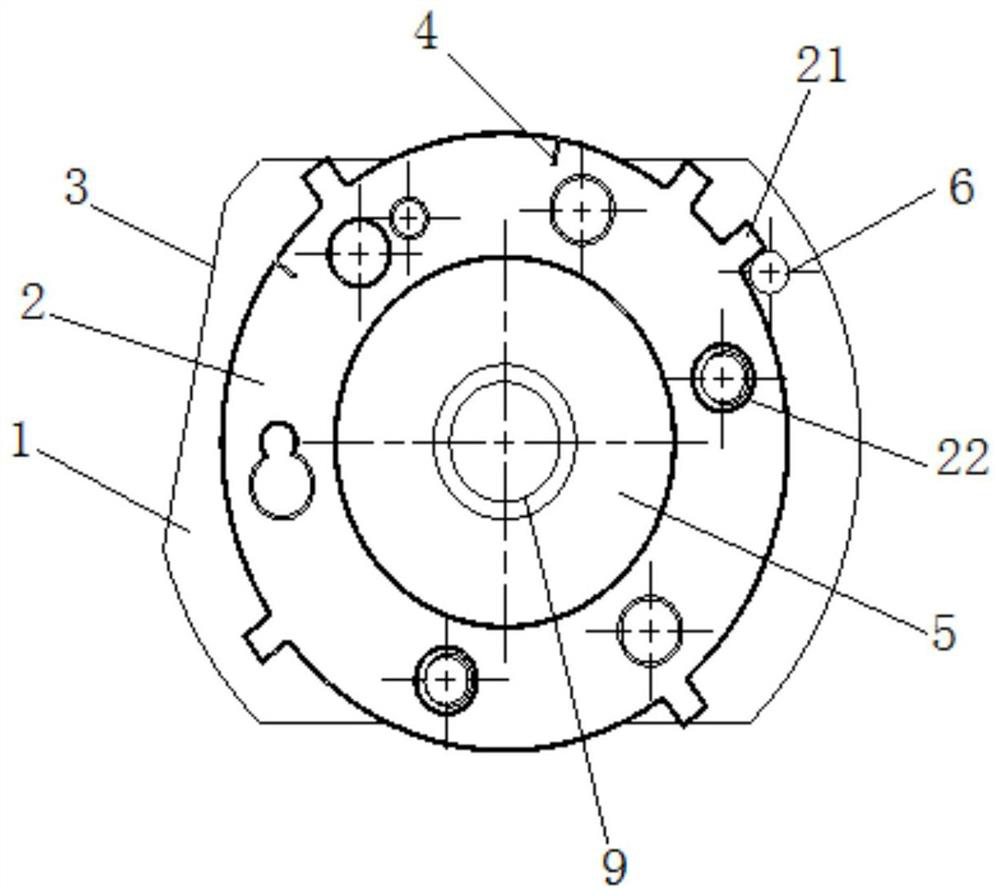

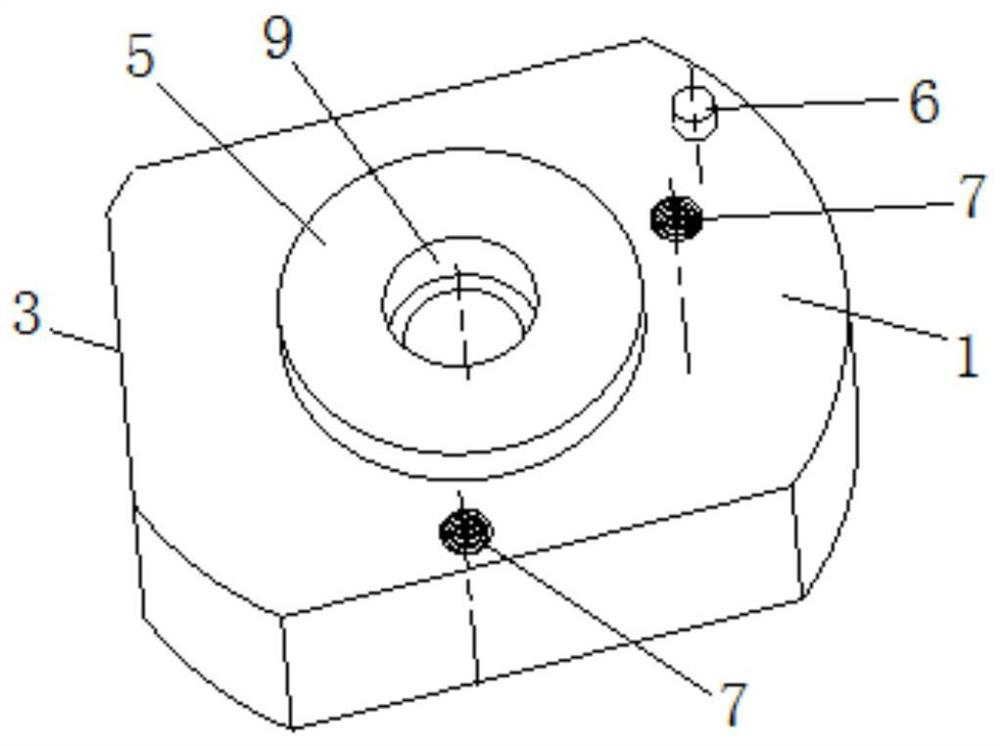

[0025] The specific embodiment of the present invention is like this: with reference to Figure 1-4 As shown, a method for drilling and marking markings on ordinary machine tools includes the following steps: setting a support base 1 on the machine tool table to support the signal plate 2, and setting a positioning structure on the support base 1 to support the signal plate 2. Position the disk 2; set the marking line tool alignment surface 3 at one end of the support base 1 and adjust the position of the support base 1 so that the marking line tool alignment surface 3 is parallel to the X-axis direction of the worktable, and the milling cutter is aligned with the marking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com