Electric spindle for numerical control machines

一种数控机床、电主轴的技术,应用在铣床、铣床设备、金属加工机械零件等方向,能够解决电主轴重量降低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

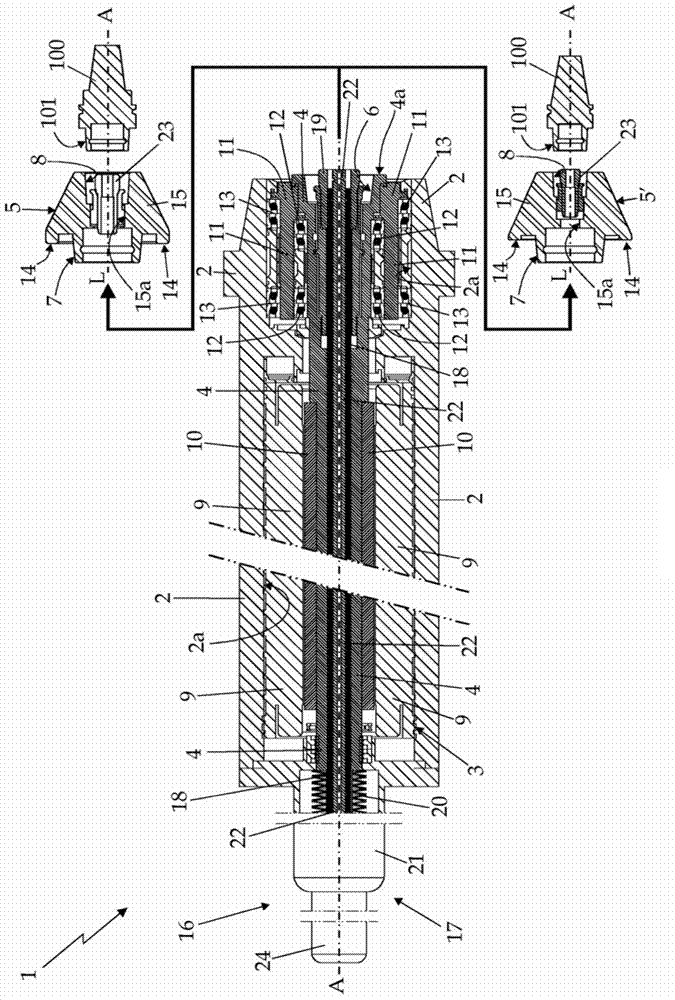

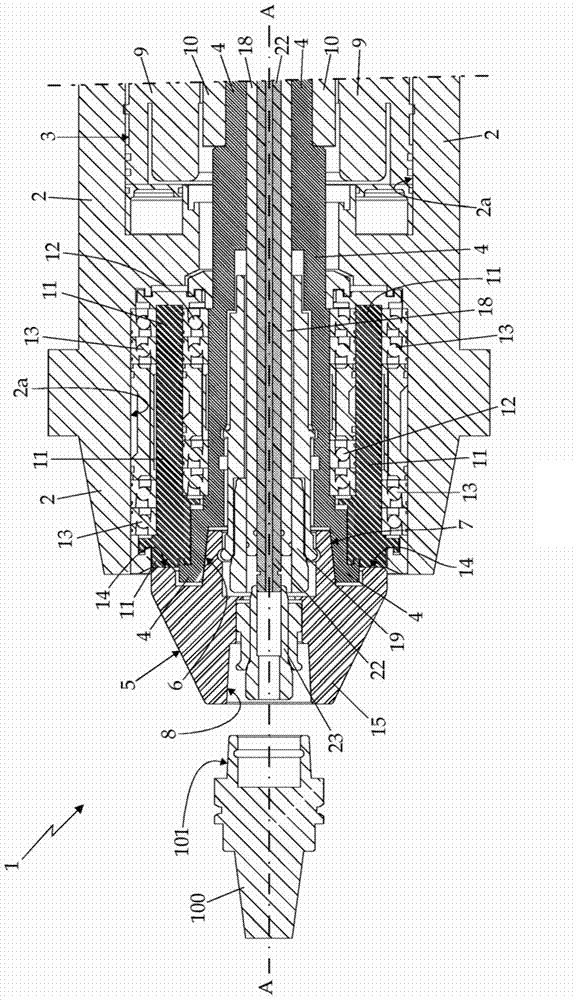

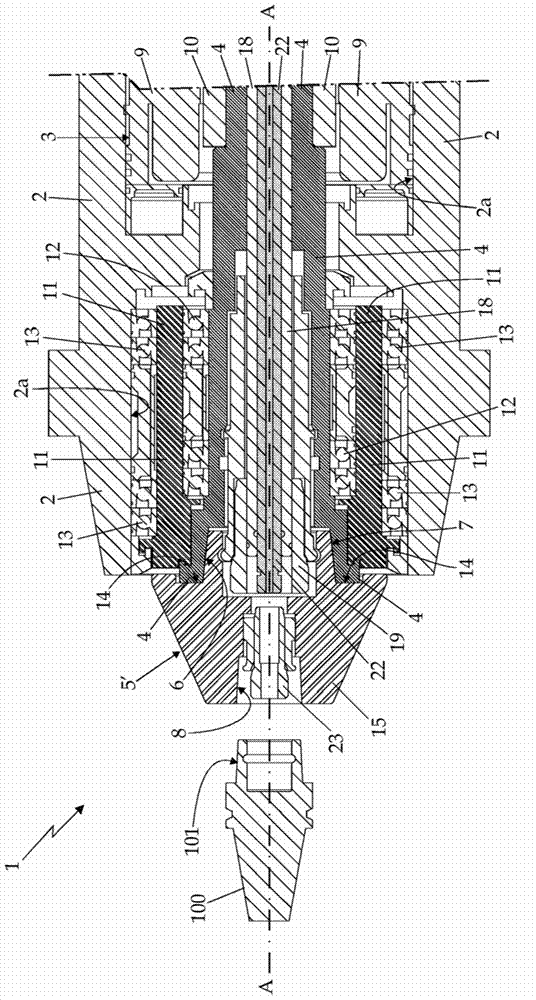

[0022] refer to figure 1 , figure 2 with image 3 , reference numeral 1 denotes an integral motorized spindle for numerically controlled machine tools, which has a longitudinal reference axis A and is configured to selectively lock the universal tool 100 and drive the universal The tool 100 rotates. The electro-spindle 1 has also been found to be particularly advantageous for use in numerically controlled grinding machines.

[0023] The electro-spindle 1 basically comprises: an outer structural housing 2 configured to be rigidly attachable to the spindle bracket or slide (not shown) of any CNC grinding or similar machine tool; an electric motor 3 , the electric motor 3 is stably housed in the structural housing 2 and is provided with a drive shaft 4 which protrudes / exposes with its front end 4a to the structural housing while remaining partially coaxial with the electric spindle axis A the exterior of the body 2; and at least one tool holder head 5 configured to be attach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com