Stacked chicken cages for free-range laying hens

A technology for laying hens and chicken cages, applied in the field of chicken cages, can solve the problems of reducing egg production and egg production quality of laying hens, laying hens not being able to stand to eat, and harming the welfare of laying hens, etc. The effect of living welfare and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

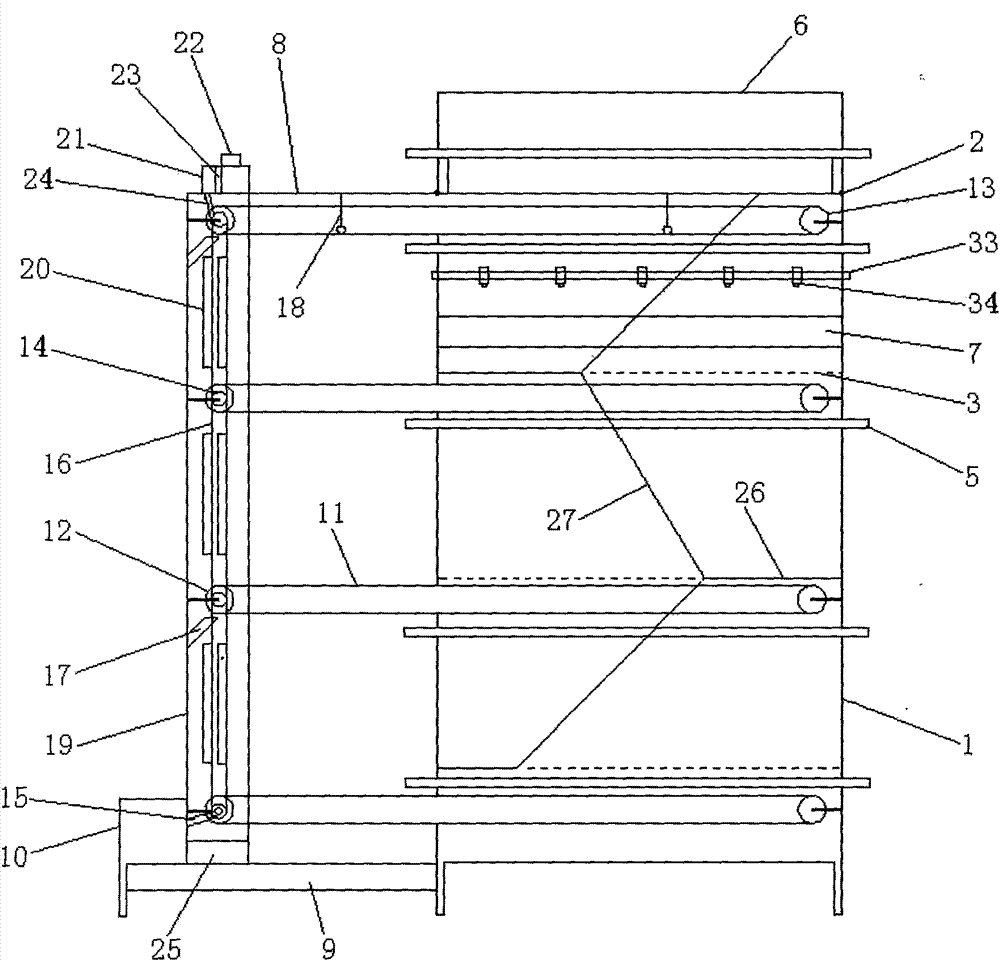

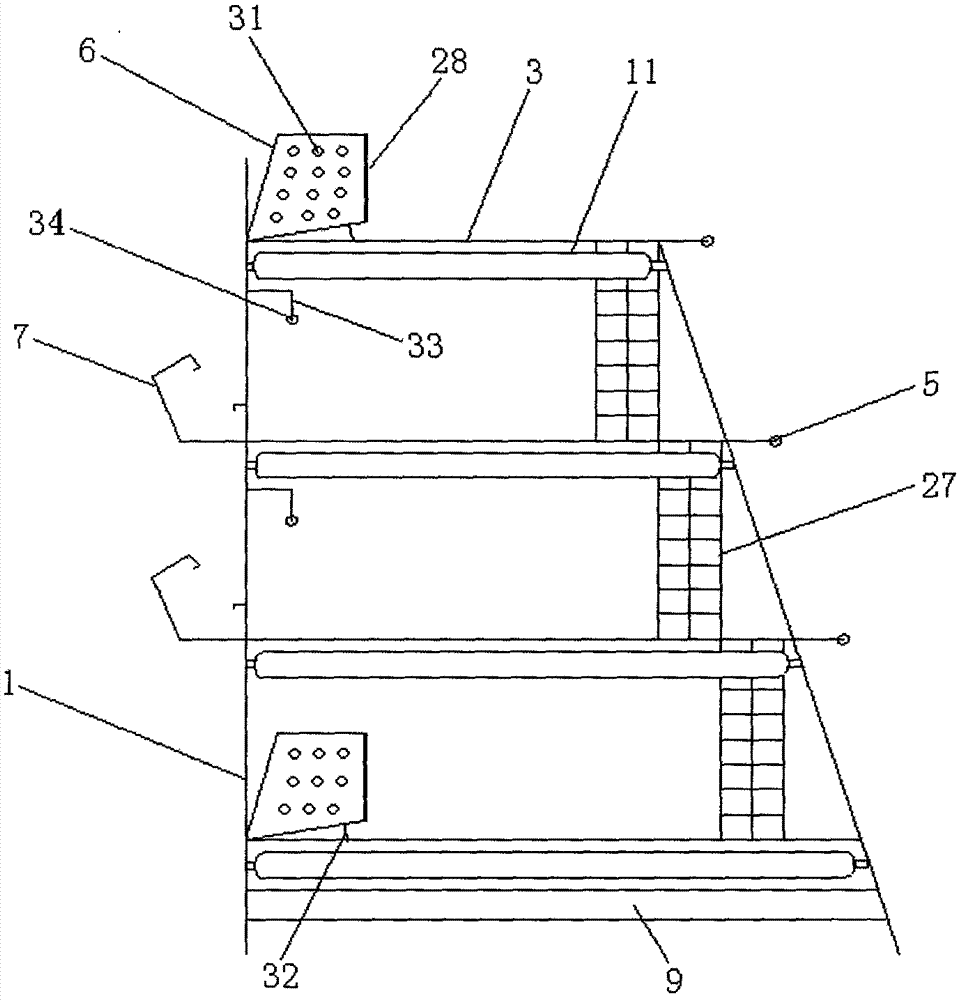

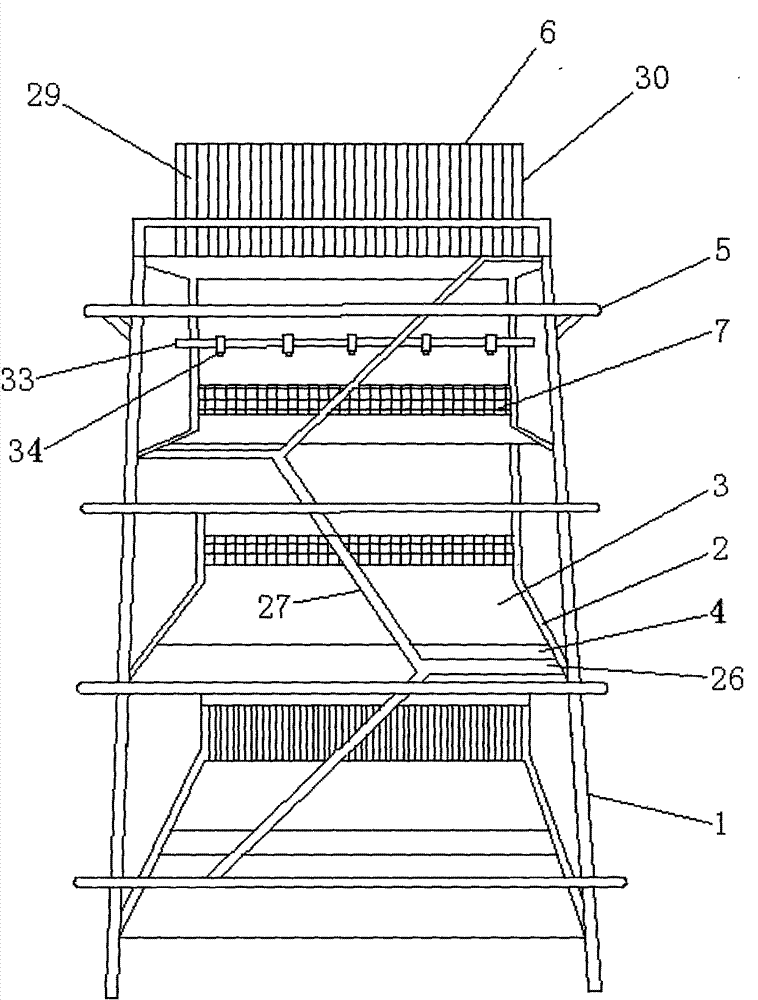

[0049] Example 1, such as figure 1 , figure 2 , image 3 As shown, a stacked chicken cage for feeding free-range laying hens includes a trapezoidal cage 1, an automatic manure cleaning mechanism is arranged on the side of the trapezoidal cage 1, and a cross brace 2 is arranged in the middle of the trapezoidal cage 1, and the cross brace 2 There is a bottom net 3 in the middle, and the bottom net 3 is distributed in parallel up and down. A mesh ladder is arranged in front of the adjacent two layers of bottom net 3, and a drain 4 is arranged between the mesh ladder and the bottom net 3. Both ends are connected with the cross brace 2, the front end of the cross brace 2 is provided with a perch 5, the rear end of the upper surface of the bottom net 3 is provided with an egg laying box 6, and the trapezoidal cage frame 1 below the bottom net 3 is provided with a drinking fountain. The rear is provided with a trough 7, and the automatic manure cleaning mechanism includes a frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com