A cupping device that prevents falling off

A cupping device and anti-shedding technology, applied in the field of medical devices, can solve the problems of unsatisfactory use effect, shedding, discomfort of patients, etc., and achieve the effects of not easily falling off, stimulating acupoints, and promoting blood circulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

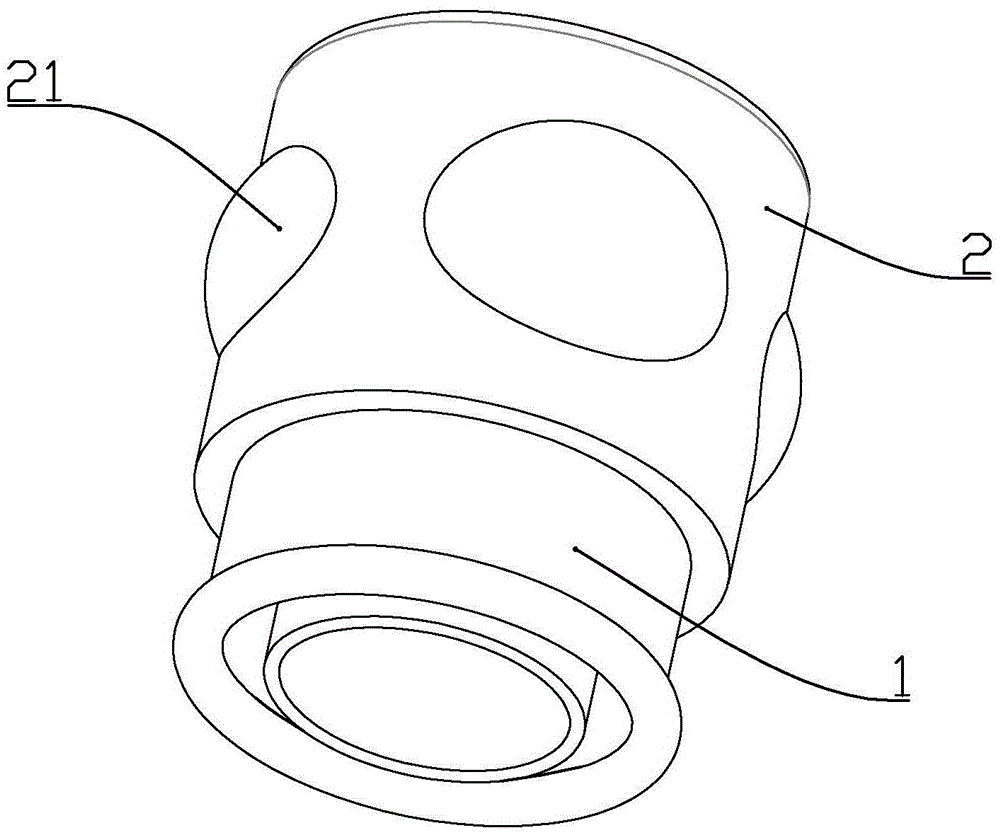

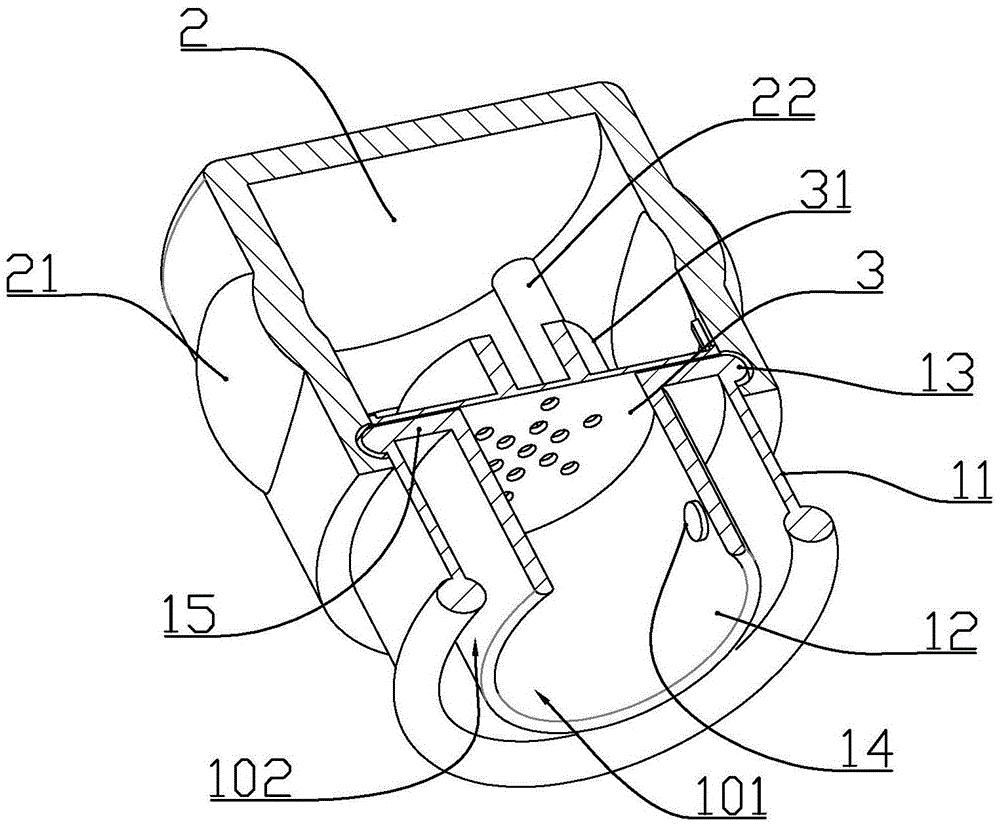

[0014] according to Figure 1 to Figure 3 As shown, the anti-falling cupping device described in this embodiment includes an integrally formed plexiglass tube body 1 and an elastic rubber bowl 2 sleeved at one end of the tube body to generate negative pressure; The plexiglass tube body comprises a circular outer tube body 11 and an inner tube body 12 coaxially arranged with the outer tube body, and one end of the inner tube body and the outer tube body is connected by an annular connecting wall 15 An annular outer cavity 102 is formed between the outer tube body and the inner tube body, and an inner cavity 101 is formed in the inner circumference of the inner tube body and the elastic rubber bowl; A one-way valve 14 that leads to the inner cavity in one direction; an outer flange 13 is formed on the outer side wall of the outer tube body adjacent to the end of the annular connecting wall, and the position of the elastic rubber bowl near the port is formed to cooperate with the...

Embodiment 2

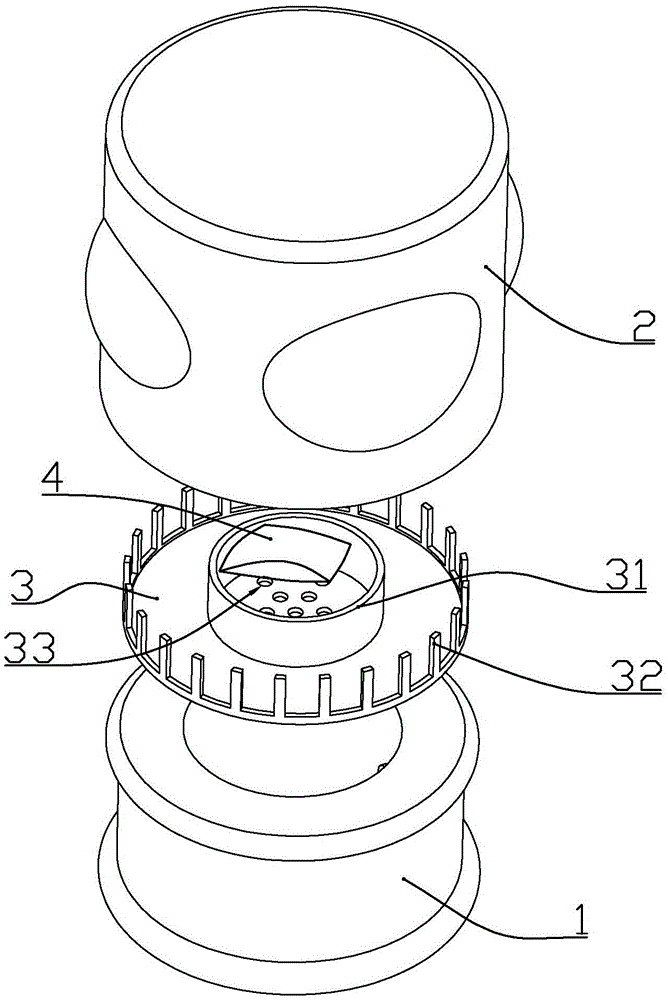

[0019] according to figure 1 , Figure 4 As shown, the anti-falling cupping device described in this embodiment includes an integrally formed plexiglass tube body 1 and an elastic rubber bowl 2 sleeved at one end of the tube body to generate negative pressure; The plexiglass tube body comprises a circular outer tube body 11 and an inner tube body 12 coaxially arranged with the outer tube body, and one end of the inner tube body and the outer tube body is connected by an annular connecting wall 15 An annular outer cavity 102 is formed between the outer tube body and the inner tube body, and an inner cavity 101 is formed in the inner circumference of the inner tube body and the elastic rubber bowl; A one-way valve 14 that leads to the inner cavity in one direction; an outer flange 13 is formed on the outer side wall of the outer tube body adjacent to the end of the annular connecting wall, and the position of the elastic rubber bowl near the port is formed to cooperate with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com