A processing tool for the zinc shell of the microphone connector

The technology of a microphone and a zinc shell is applied in the field of processing tooling of the zinc shell of the microphone joint, which can solve problems such as product surface damage, and achieve the effects of convenient operation, convenient processing and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

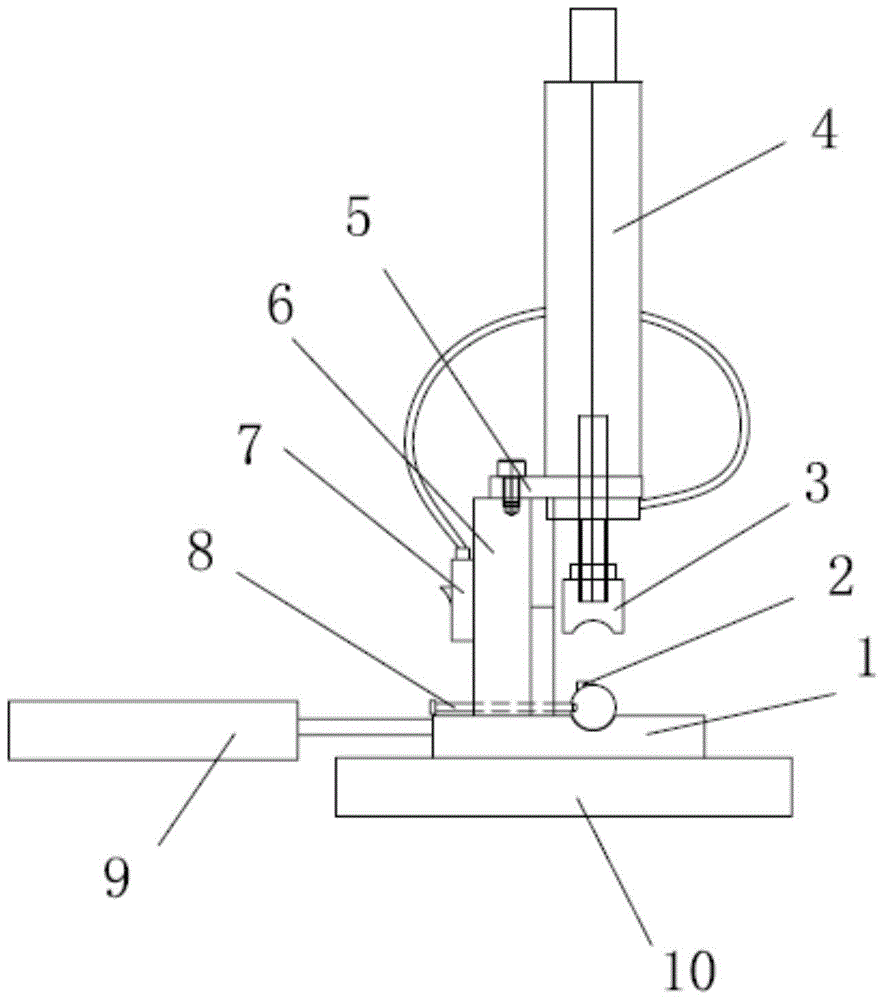

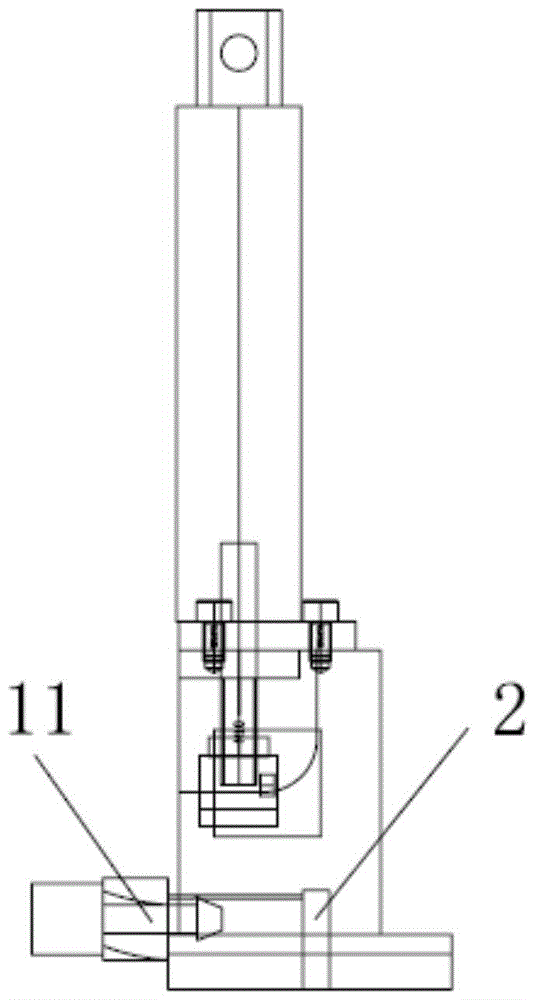

[0020] First place the product in the positioning groove 21 on the upper end surface of the positioning seat 1, and make one end of the product close to the fixed insert 2 of the zinc shell, and at the same time insert the product through the positioning insert 8 to prevent the product from rotating, and then control the switch 7 to make Press down the cylinder 4 to lock the product through the groove at the lower end of the fixed block 3 and the positioning groove 21, then insert the lathe tool 11 into the product and rotate it, and then control the push cylinder 9 through the control switch 7 , so that the positioning seat 1 slides, so that the lathe tool 11 processes the inside of the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com