Protecting cover structure for machining equipment

A technology of mechanical processing and protective cover, which is applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., which can solve the problems of reducing the size, increasing the area occupied by a single device, and increasing the working space of the protective device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific embodiment:

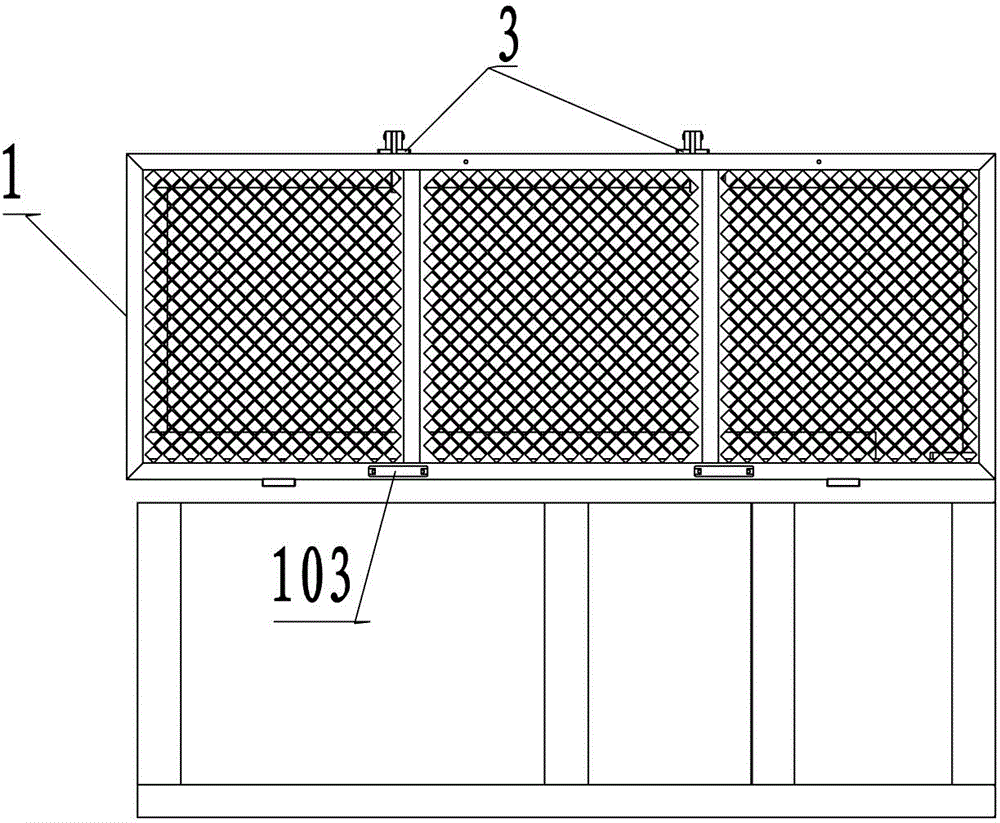

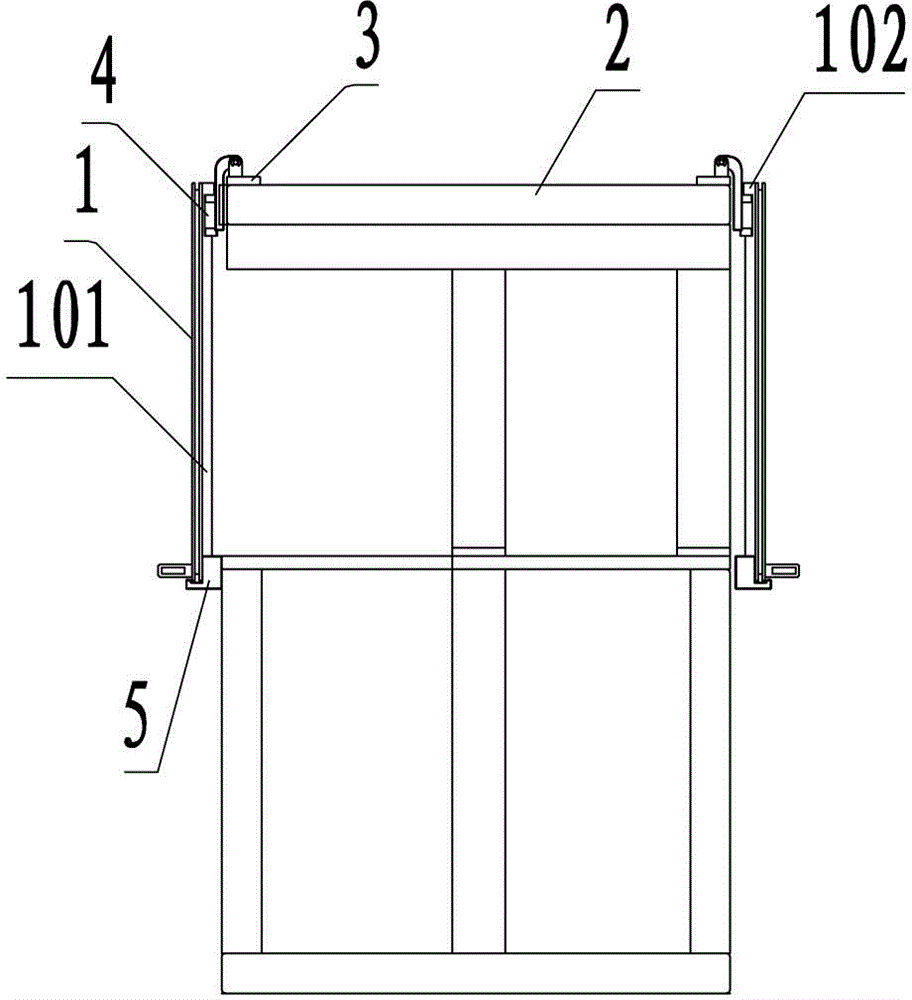

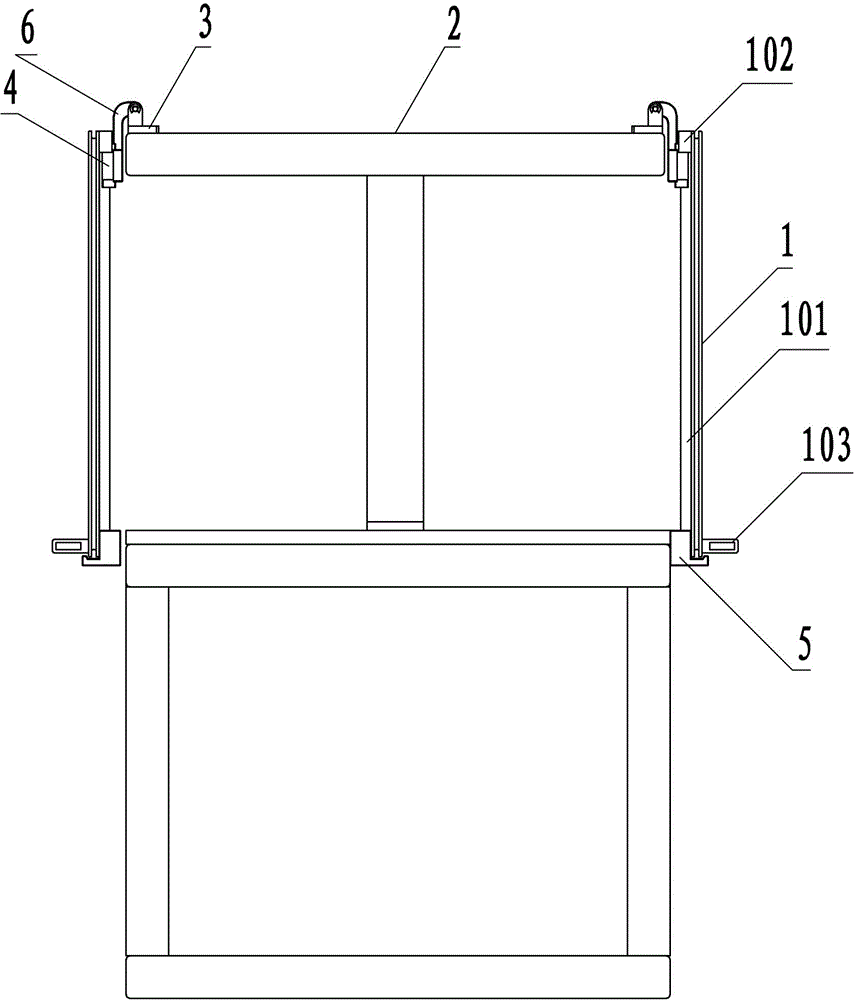

[0021] See attached figure 1 to attach image 3 As shown, what is described in this embodiment is a protective cover structure used on machining equipment. In this embodiment, the protective cover structure is installed on the front and rear sides of the mechanical processing equipment, wherein the protective cover structure includes as The protective part 1 of the main body, the fixed support 3 fixed on the top of the frame 2, the slider 4 and the protective part bracket 5. The protective part 1 can be made of tempered glass or a metal safety net, preferably a safety net. The inner side of the main body of the aluminum alloy frame of the safety protection net is vertically fixed with a guide rail 101, and the safety protection net forms a sliding connection with the slider 4 through the guide rail 101 on it, wherein the slider 4 is installed by a hinge slider The flange ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com