A cam pre-installation error-proof tooling device

A technology for assembling tooling and error-proofing, applied in workpiece clamping devices, measuring devices, manufacturing tools, etc., can solve problems such as affecting mechanical properties, increasing labor strength, inconvenient disassembly and assembly, etc., which is conducive to industrialized automatic production, saving The effect of human and material investment and improving the quality of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

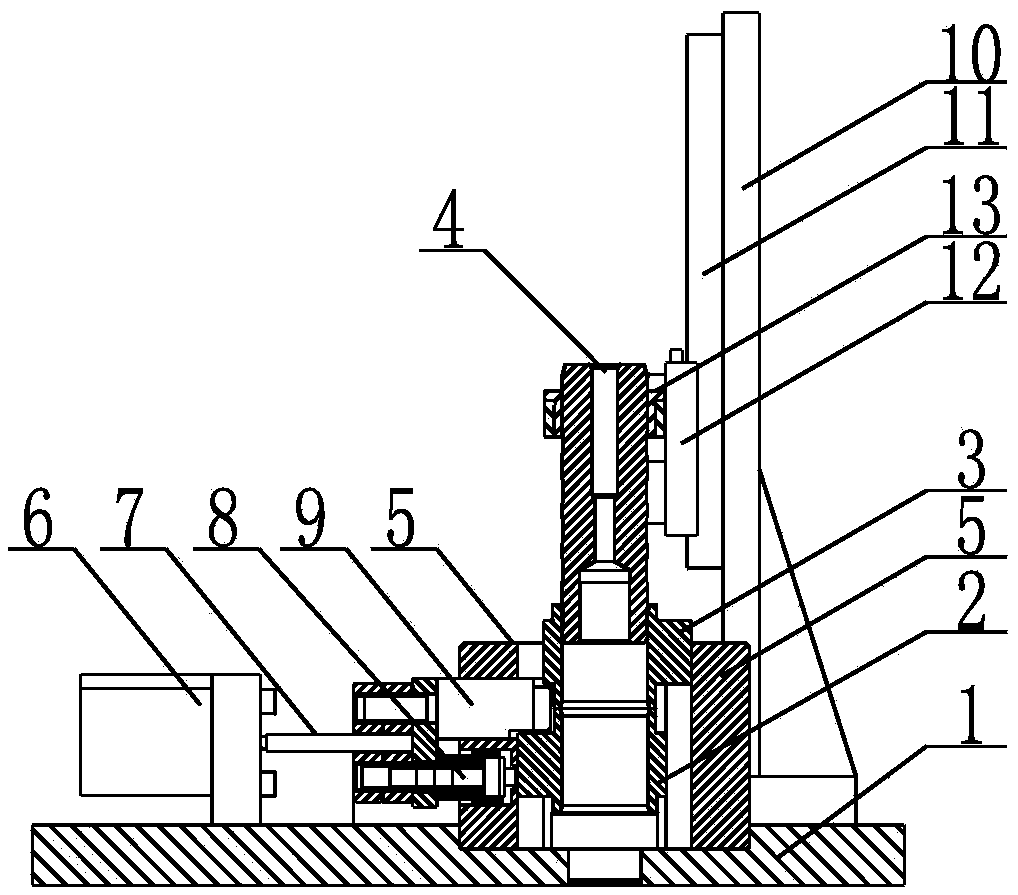

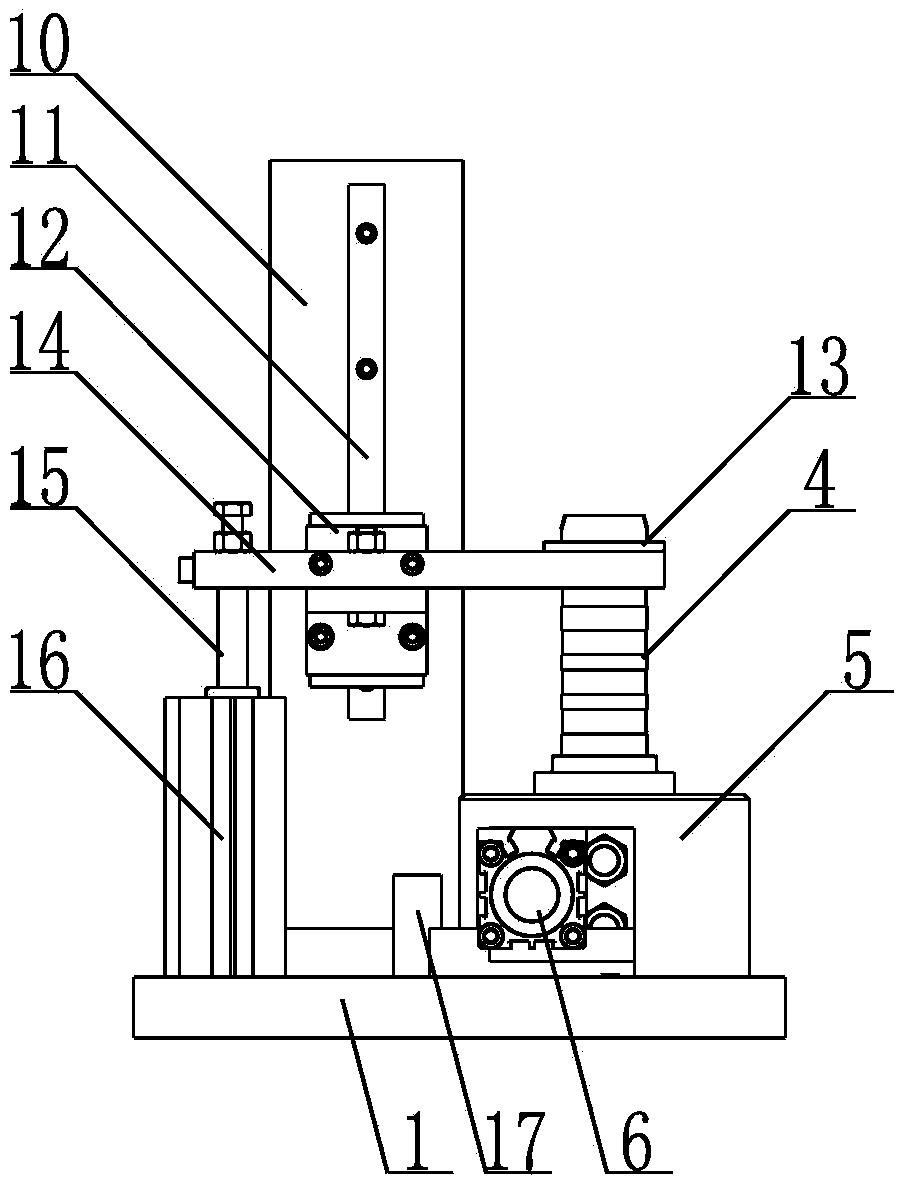

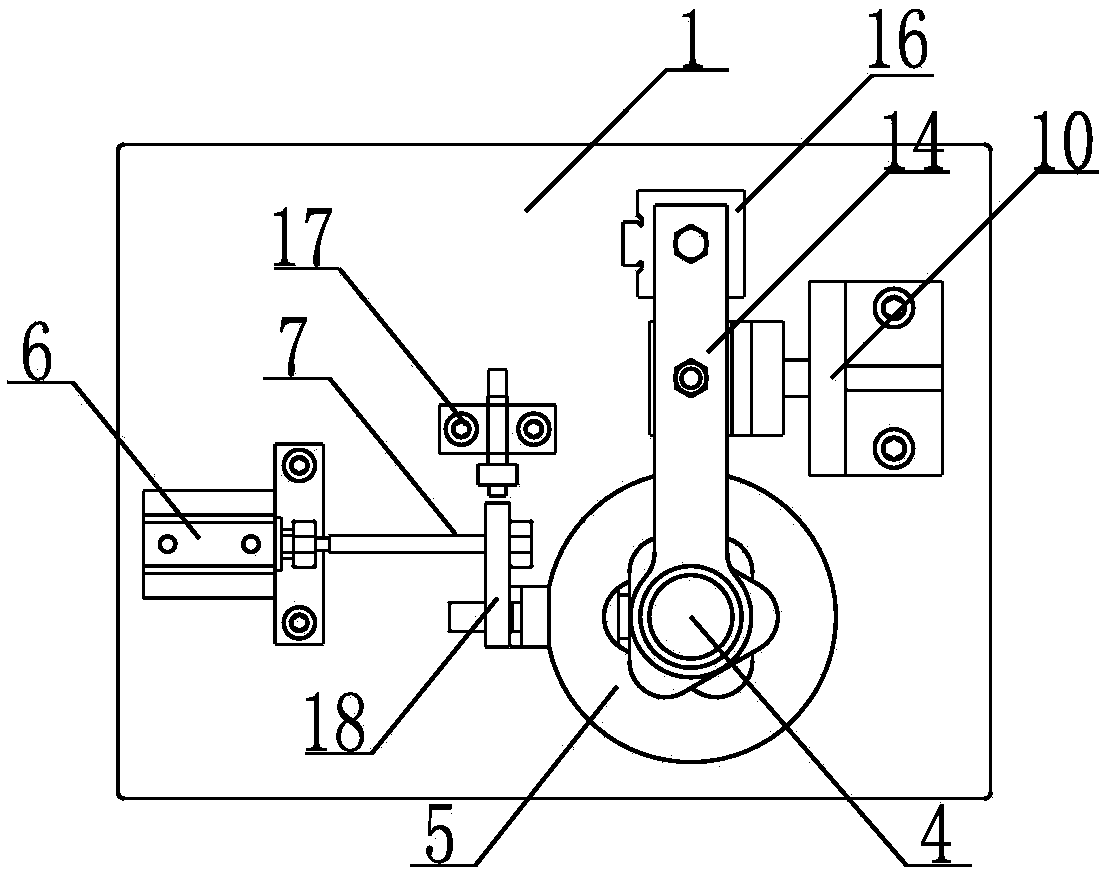

[0023] Embodiment 1: see figure 1 , figure 2 , image 3 , a cam pre-installation error-proof tooling device, including an assembly tooling base plate 1, a first cam piece 2, a second cam piece 3, and a mandrel 4, and the first cam piece 2 and the second cam piece 3 are sequentially staggered on the On the mandrel 4, the assembly tool base 1 is provided with error-proof tooling parts, cam sheet detection parts, and mandrel centering parts,

[0024] The cam plate detection component includes a horizontally arranged cylinder a6, a cylinder connecting rod a7, a wrong-proof pin connecting plate 18, and connects the first wrong-proof pin 8 and the second wrong-proof pin 9. The cylinder a6 is fixedly connected to the bottom plate 1 of the assembly tool through the cylinder connection support, the pin head of the first anti-error pin 8 is in contact with the protruding part of the first cam plate 2, and the pin head of the first anti-error pin 8 The pin head is provided with a con...

Embodiment 2

[0028] Embodiment 2: the cam piece is triangular in shape, and the cross section of the groove formed by the through groove a19 and the through groove b20 of the positioning tool 5 is spline-shaped, as Figure 4 , Figure 5 As shown, other technical solutions and working principles are the same as those in Embodiment 1.

Embodiment 3

[0029] Embodiment 3: The number of cam pieces is N, and N is an integer number. The number of through slots and the number of error prevention pins on the positioning tool 5 are correspondingly set according to the specific number of cam pieces. Other technical solutions and working principles are related to the embodiment 1 is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com