A kind of unwinding device linked with host and its installation method

A technology of unwinding device and linkage, which is applied in the direction of needle punching machine, winding strip, transportation and packaging, etc. It can solve problems such as single product, inability to directly process non-woven fabrics, and inability to meet market demand, and achieve labor The effect of low strength, high flatness and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

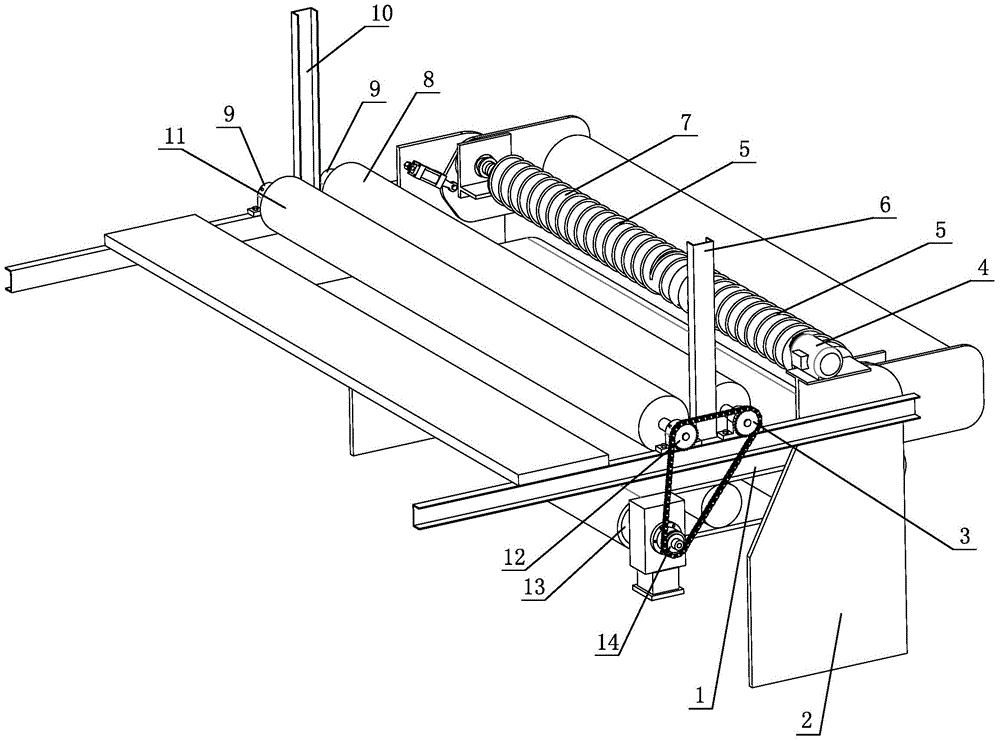

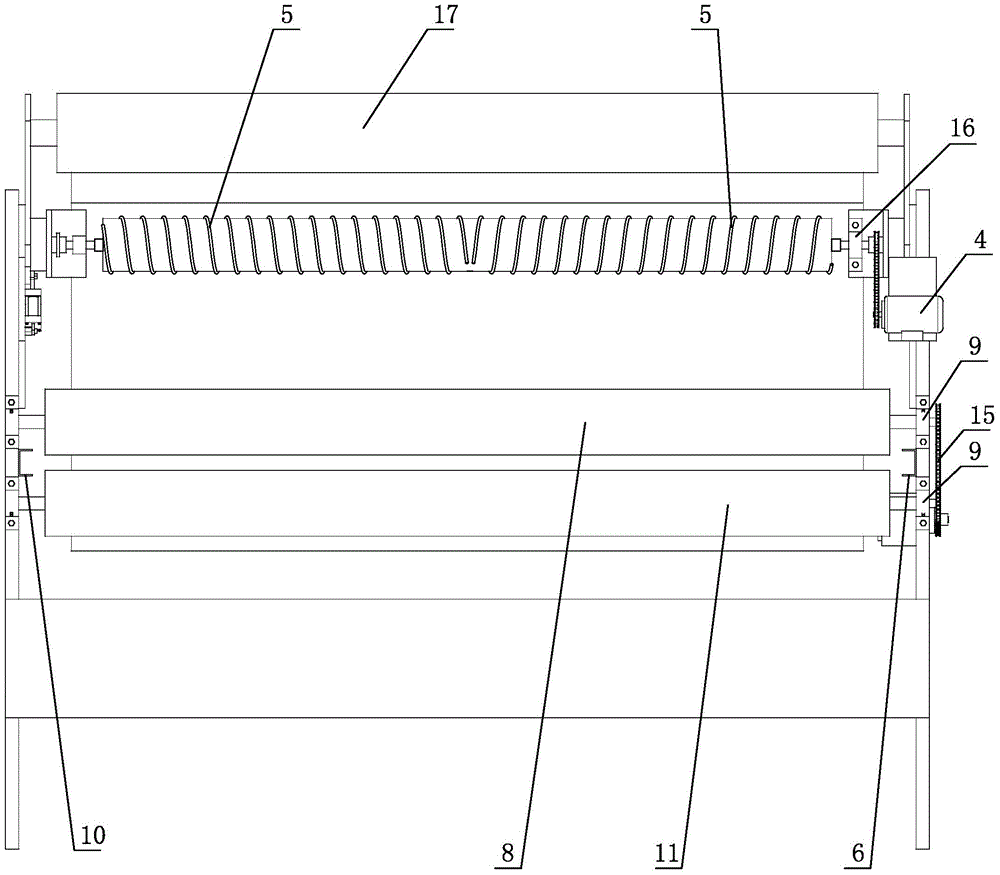

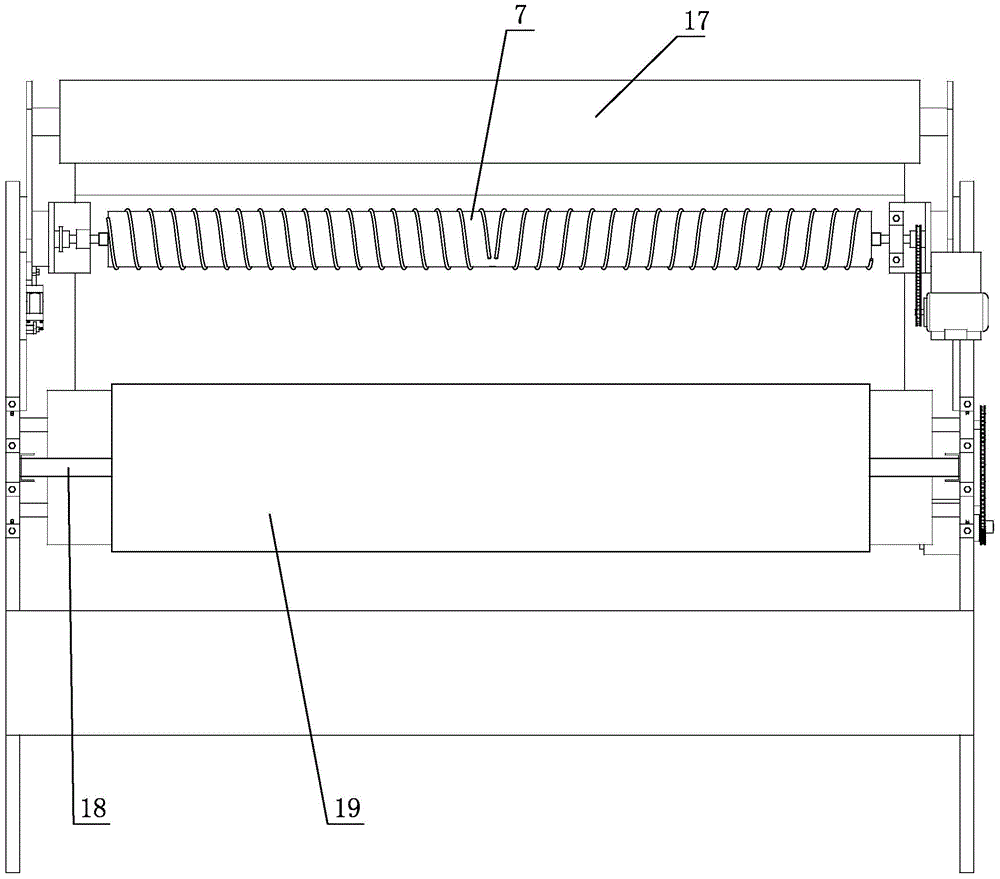

[0018] like figure 1 , figure 2 As shown, a kind of unwinding device of the present invention linked with the main engine is installed above the conveying bottom curtain 1 of the needle punching production line, and includes unwinding roller 11, unwinding roller 11, unwinding roller Two 8, fabric arrangement roller 7; unwinding roller one 11, unwinding roller two 8 are arranged in parallel on the same horizontal plane, the two ends of unwinding roller one 11, unwinding roller two 8 are all installed on the frame by support bearing one 9 2, and are jointly driven by the main rotating shaft 13 of conveying the bottom curtain 1; the two ends of the fabric roller 7 are installed on the frame 2 through the support bearing 2 16, and are driven by the motor 4; the frame 2 is also vertically fixed There are channel steel one 6 and channel steel two 10, channel steel one 6 is located between the end of the same side of unwinding roll one 11 and unwinding roll two 8, channel two 10 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com