Wind turbine blade with trailing edge flat plate

A technology of wind turbine blades and flat plates, which is applied to wind engines, wind turbine components, engines, etc., can solve the problems of increased manufacturing costs, and achieve the effect of simple and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

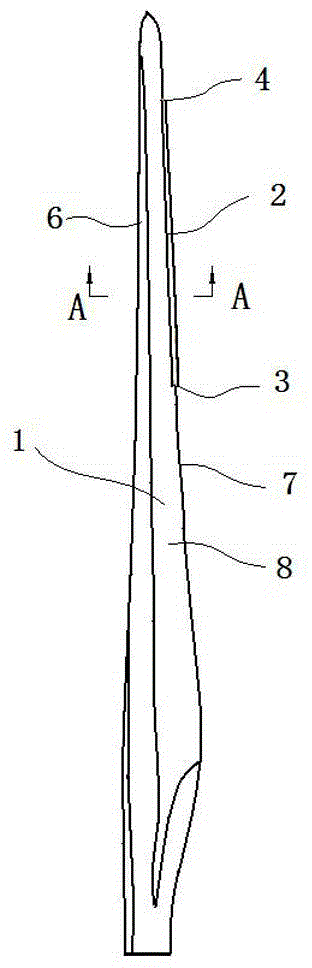

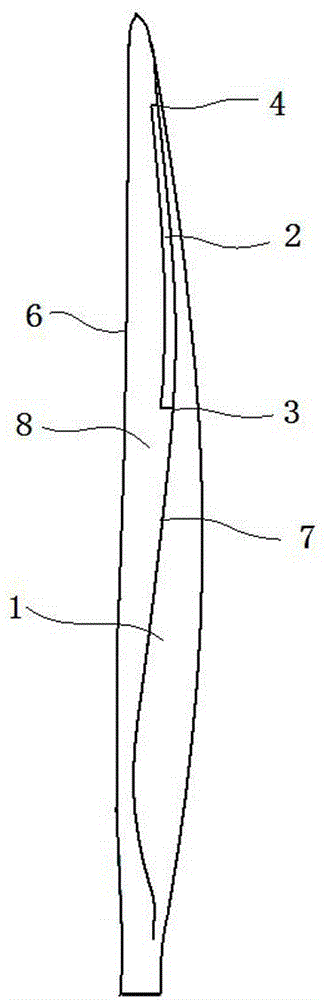

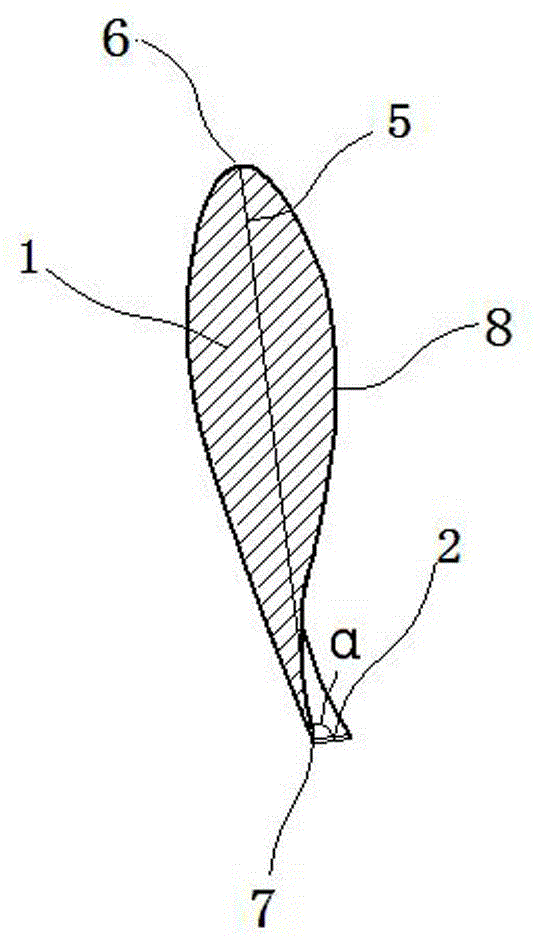

[0019] Embodiment 1: as Figure 1 to Figure 3 As shown, a wind turbine blade with a trailing edge plate structure includes a blade 1, a trailing edge plate 2 is installed on the trailing edge of the blade 1, and the trailing edge plate 2 is installed close to the trailing edge 7 of the blade. One side of the trailing edge plate 2 is close to the trailing edge 7 of the blade, and the other side is higher than the windward surface 8 of the blade. The blade section airfoil chord 5 is between the blade leading edge 6 and the blade trailing edge 7; The included angle α is 0°~90°. The trailing edge plate 2 is divided into multiple sections, and each section of the trailing edge plate 2 has a smooth transition. The trailing edge plate structure is positioned between the 60% span position and the 90% span position of the blade. The width of the trailing edge plate is 5% times the chord length of the blade section airfoil.

[0020] For wind turbines with variable speed and pitch co...

Embodiment 2

[0023] Embodiment 2: The difference from Embodiment 1 is that the width of the trailing edge plate is 1% times the chord length of the blade section airfoil; the rest is the same as Embodiment 1.

Embodiment 3

[0024] Embodiment 3: The difference from Embodiment 1 is that the width of the trailing edge plate is 2% times the chord length of the blade section airfoil; the rest is the same as Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com