Packing sealing structure of needle-shaped cutoff valve

A technology of packing seal and globe valve, which is applied in the direction of shaft seal, valve detail, valve device, etc., can solve the problems of packing leakage and shortening service life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

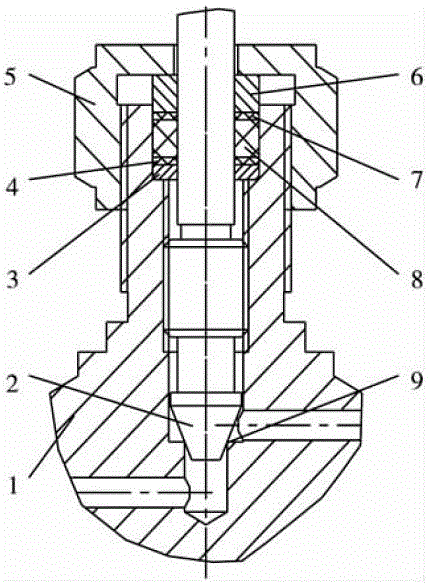

[0013] Such as figure 1 As shown, the packing sealing structure of the needle stop valve of the present invention includes a valve body 1, and a medium channel with a height difference is opened transversely on the valve body 1, so that the medium channel forms a vertical sealing section. There is a vertical valve core inside the valve body 1, the end of the valve core is a conical disc 2, and the conical surface of the conical disc 2 is the main sealing surface 9 of the vertical sealing section in the sealing medium channel; the valve The upper part of the body 1 is also provided with a packing chamber, and the upper packing pressure pad 6, the upper packing retaining pad 7, the packing 8, the lower packing retaining pad 4 and the lower packing pressing pad 3 are sequentially placed in the packing chamber. There is also a packing pressure cap 5 on the top of the valve body 1, which is used to compress the above-mentioned packing structure. The spool runs through the lower pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com