Photovoltaic power station dedusting brush

A photovoltaic power station and dust removal brush technology, applied in the field of solar photovoltaic power generation, can solve the problem of high water cost, achieve the effects of uniform pressure, surface finish protection, convenient and cheap replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

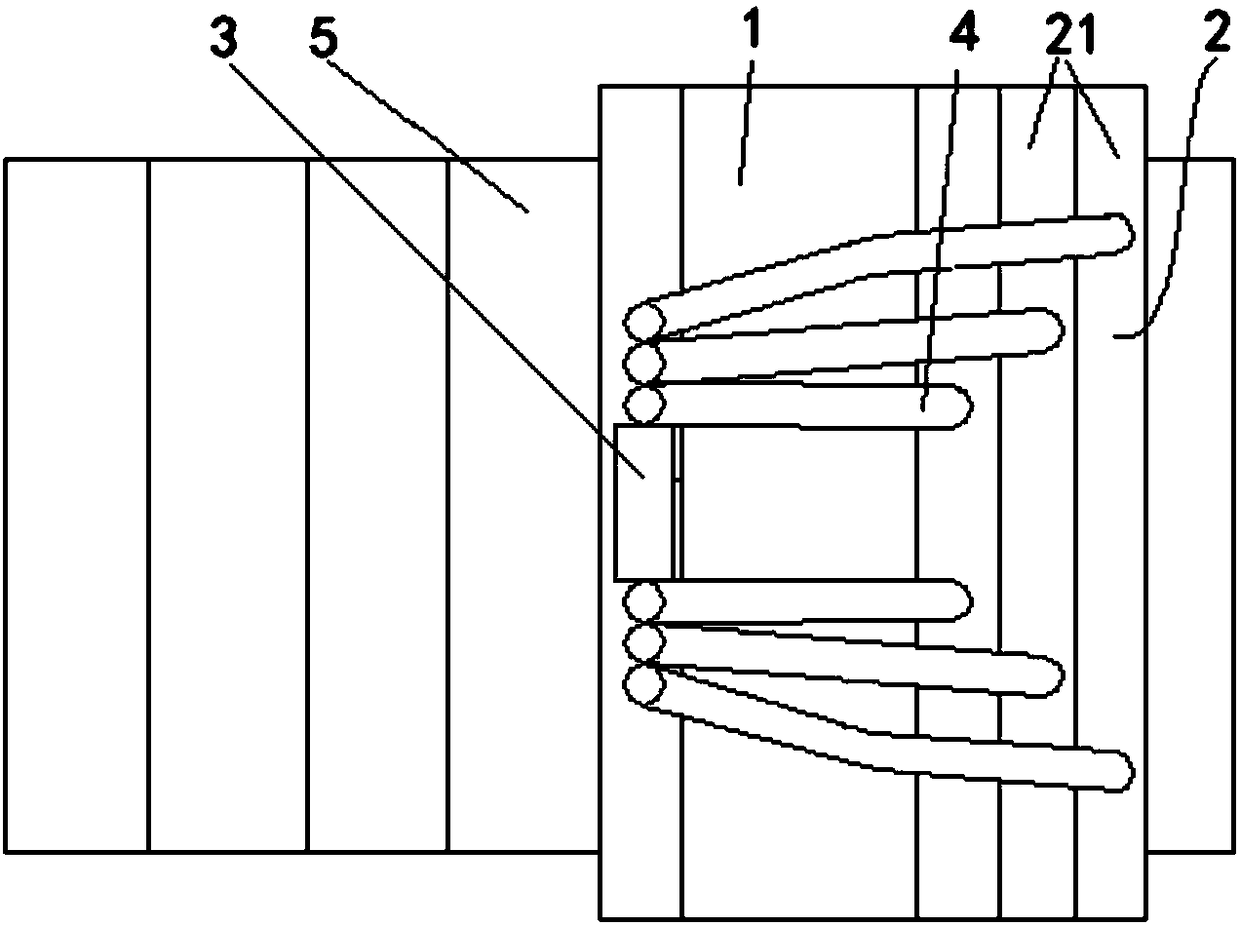

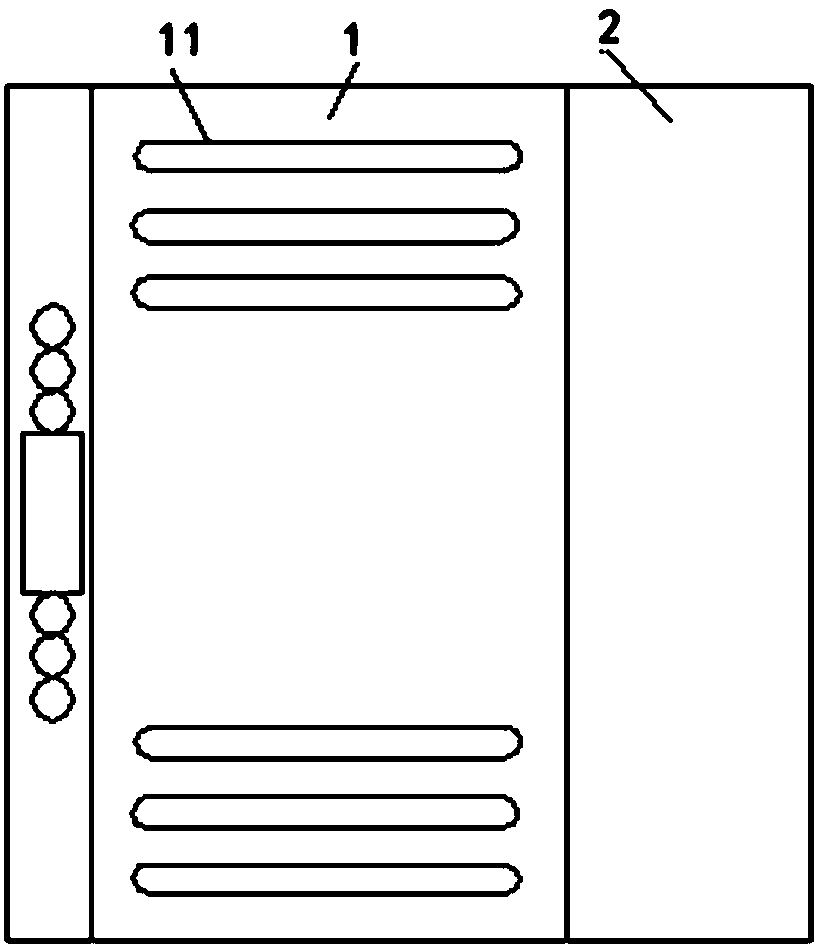

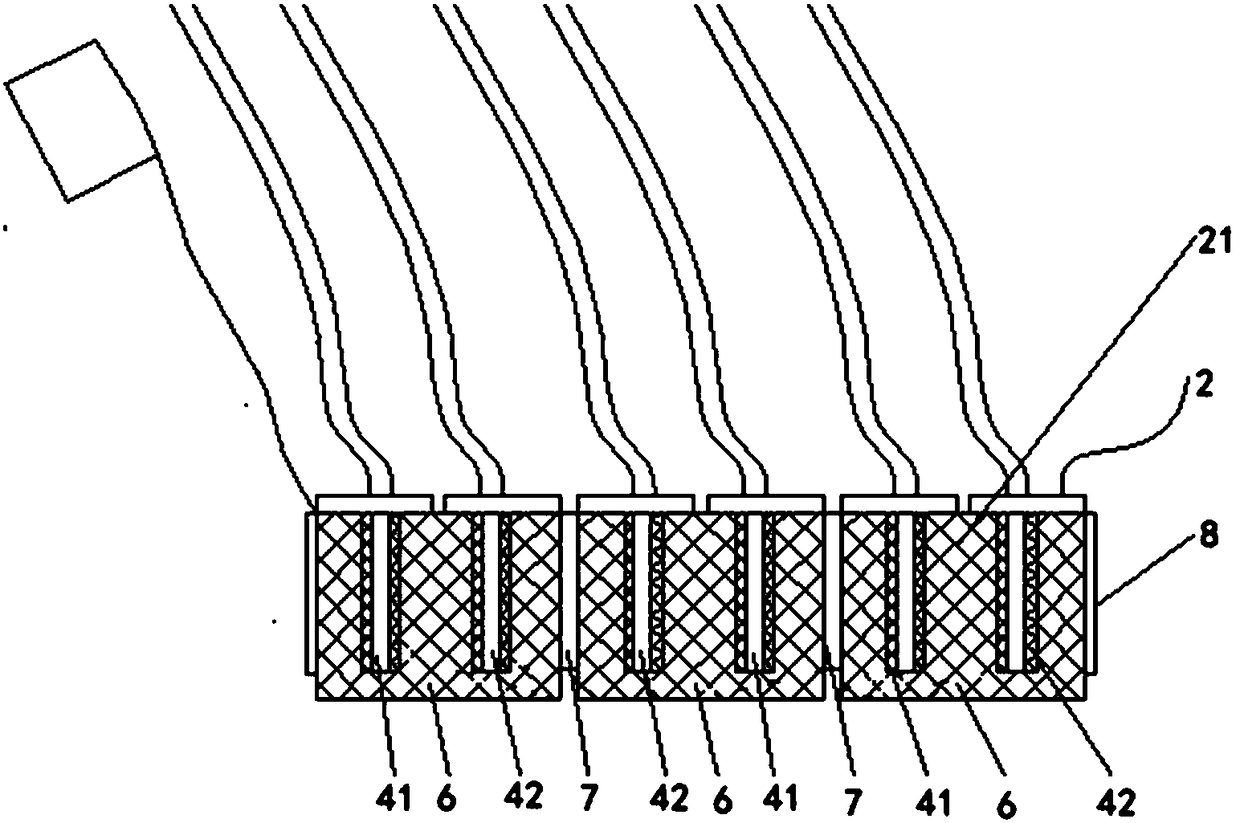

[0023] Such as Figure 1-4 As shown, the present invention discloses a dust removal brush for a photovoltaic power station, which includes a spring steel sheet 1, a dust removal panel 2 and a connecting rod. One end of the connecting rod 3 is fixed on a mobile device and is driven by the mobile device. The connecting rod The other end of 3 is fixedly connected to one end of the spring steel sheet 1, and the other end of the spring steel sheet 1 is connected to the dust removal panel 2. The bottom periphery of the dust removal panel 2 is provided with a soft frame 8. A plurality of cleaning areas 21, each cleaning area 21 is detachably provided with a cleaning brush 6, and each cleaning area 21 is fixedly inserted with a group of elongated tube groups 4, and the elongated tube groups 4 are used for cleaning brushes. water or air supply.

[0024] Such as figure 2 As shown, the spring steel sheet 1 is provided with a plurality of long windows 11, so as to adapt to the deformat...

Embodiment 2

[0032] Such as figure 1 , 2 , 5 and 6, the difference between this embodiment 2 and embodiment 1 is:

[0033] The cleaning brush 6 is a wiping brush made of fine velvet cloth. The wiping brush comprises a hard foam layer 62 and a fine velvet cloth layer 64 arranged up and down. Fine velvet layer 64 can be stuck on the hard foam layer 62 below, every period of time with the car in water to clean, dry, and then to the next work area, if necessary, can make the velvet strip non-stick water easier to clean and dry.

[0034] The strip tube group 4 includes at least one negative pressure suction tube 43 and at least one high pressure air injection tube 44 .

[0035] The dust removal panel 2 is provided with a pre-blowing hole 22 facing the photovoltaic panel 5 corresponding to the traveling direction, and the pre-blowing hole 22 removes large particles in front of the dust removal panel 2 to prevent loss of the optical surface.

[0036] This embodiment 2 adopts the above technic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com