Air blowing type limiting gauge

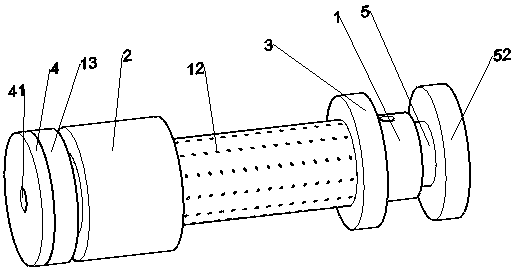

A limit gauge and pneumatic technology, which is applied in the field of manufacturing auxiliary tools, can solve problems such as limit gauge wear, and achieve the effects of reducing friction, improving production quality and reducing wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

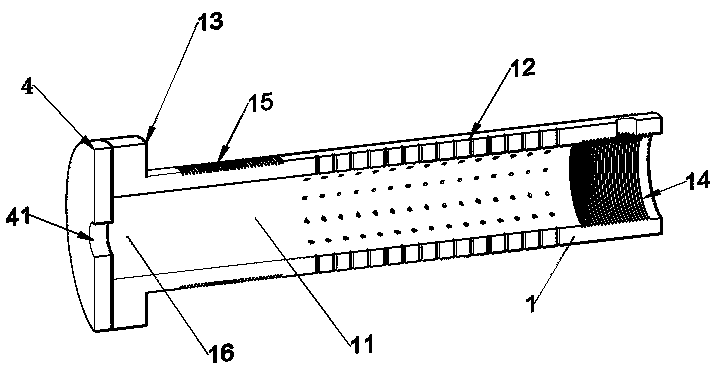

[0038] As a preferred embodiment, the sealing cover plate is a circular cover plate with a diameter equal to that of the flange 13 . The sealing cover plate is set to protect the gas leakage on the left side.

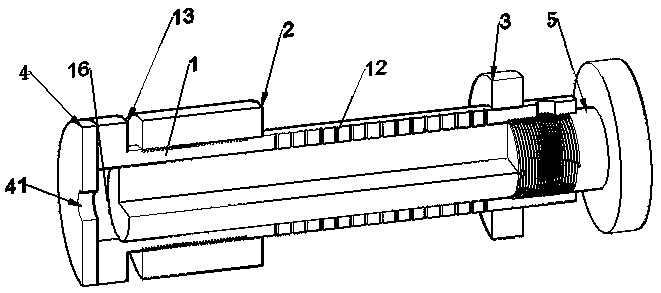

[0039] The air-blowing limit gauge of this embodiment enters the inside of the limit gauge by introducing gas, and sprays the gas onto the upper surface of the limit gauge through the air outlet, that is, the lower surface of the conveying material. To achieve the purpose of reducing the friction between the coil and the limit gauge. At the same time, the blown air can reduce the dust and ink on the limit gauge and improve the production quality. The inner core 5 of the limit gauge is installed on the material assembly line transmission equipment. When the outer gauge needs to be adjusted, the outer limit ring 2 is rotated, and when the inner gauge needs to be adjusted, the limit flange 13 on the shaft 1 is rotated. Therefore, when in use, since the inner core 5 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com