A Method of Mounting and Adjusting Reflector Using a Center Deviation Measuring Instrument

A mirror and partial measurement technology, which is applied in installation, instrumentation, optics, etc., can solve problems such as low pass rate, long lens assembly and adjustment cycle, and real-time monitoring of the center position, so as to improve the efficiency of assembly and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

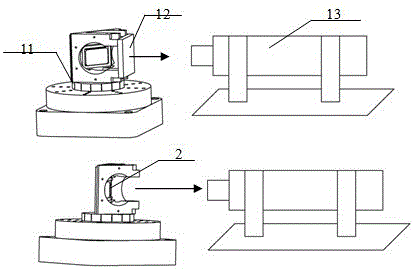

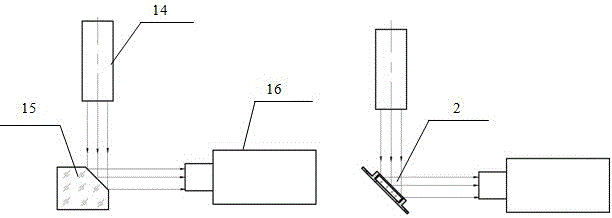

Embodiment 1

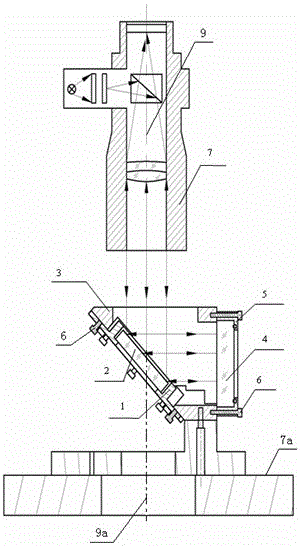

[0029] A method of using a center deviation measuring instrument to adjust the reflector group, such as image 3 , Image 6 As shown, the mirror group includes a mirror position adjustment block 1, a mirror 2, a mirror seat 3, a flat crystal 4, a flat crystal fixing seat 5, and an inner hexagon screw 6, and the center deviation measuring instrument 7 also includes a gas The floating turntable 7a is characterized in that the installation and adjustment includes the following steps:

[0030] step one: Mirror group installation

[0031] The reflector 2 is bonded in the reflector position adjustment block 1 by glue; the reflector position adjustment block 1 is installed on the reflector seat 3, and the mirror position adjustment block 1 and the reflector seat 3 are adjusted by the hexagon socket screws. The flat crystal 4 is installed on the flat crystal fixed seat 5, and then the flat crystal fixed seat 5 is installed on the reflector seat 3; the reflector seat 3 is fixed on ...

Embodiment 2

[0039] A method of using a center deviation measuring instrument to adjust the reflector group, such as Figure 4 , Figure 5 , Figure 7 As shown, the mirror group includes two mirror position adjustment blocks 1, two mirrors 2, mirror holders 3, two flat crystals 4, and hexagon socket screws 6 arranged symmetrically, and the center deviation measuring instrument 7 also includes The air-floating rotary table 7a is characterized in that the installation and adjustment includes the following steps:

[0040] step one: Mirror group installation

[0041] Glue the left and right reflectors 2 to the corresponding left and right reflector position adjustment blocks 1 respectively; install the left and right reflector position adjustment blocks 1 on the corresponding positions of the reflector base 3, Hexagonal screws respectively adjust the position between the left and right mirror position adjustment block 1 and the mirror base 3; install the flat crystal 4 on the mirror base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com