Dual-phase nanocrystalline high-frequency soft magnetic material and preparation method thereof

A technology of soft magnetic materials and nanocrystals, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of low resonance frequency, low saturation magnetization, and unsatisfactory, and achieve the effect of high resonance frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the dual-phase nanocrystalline high-frequency soft magnetic material of the present invention comprises the following steps:

[0035] a) Weigh the rare earth element R and pure Fe, Co, M according to the alloy ratio, melt the rare earth element R, pure Fe, Co, M under the protection of an inert gas to form a dual-phase master alloy, wherein the rare earth intermetallic compound R (Fe x co 1-x ) a m 12-a It accounts for 5%-95% by volume, and the rest is 3d metal alloy A;

[0036] b) A quenched alloy in an amorphous state, a nanocrystalline state or a mixed state of amorphous and nanocrystalline state is obtained by a melt rapid quenching method, and the linear speed of the melt rapid quenching is 10-80 m / s;

[0037] c) Pulverize the prepared quick-quenching alloy under the protection of antioxidants and coupling agents into alloy powders with a particle size of less than 5 microns, wherein the antioxidant is 5‰-10‰ of the alloy quality, and ...

Embodiment 1

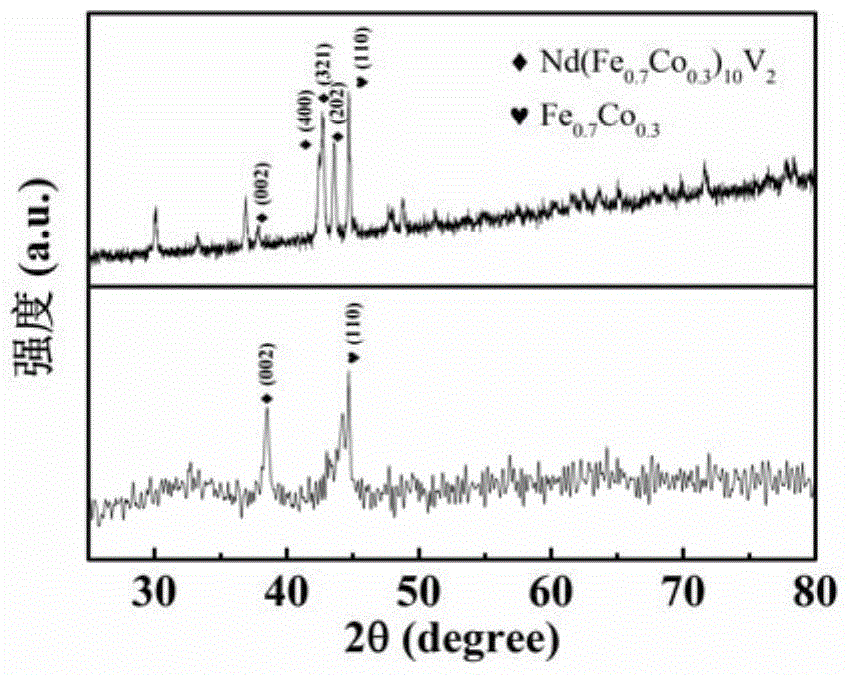

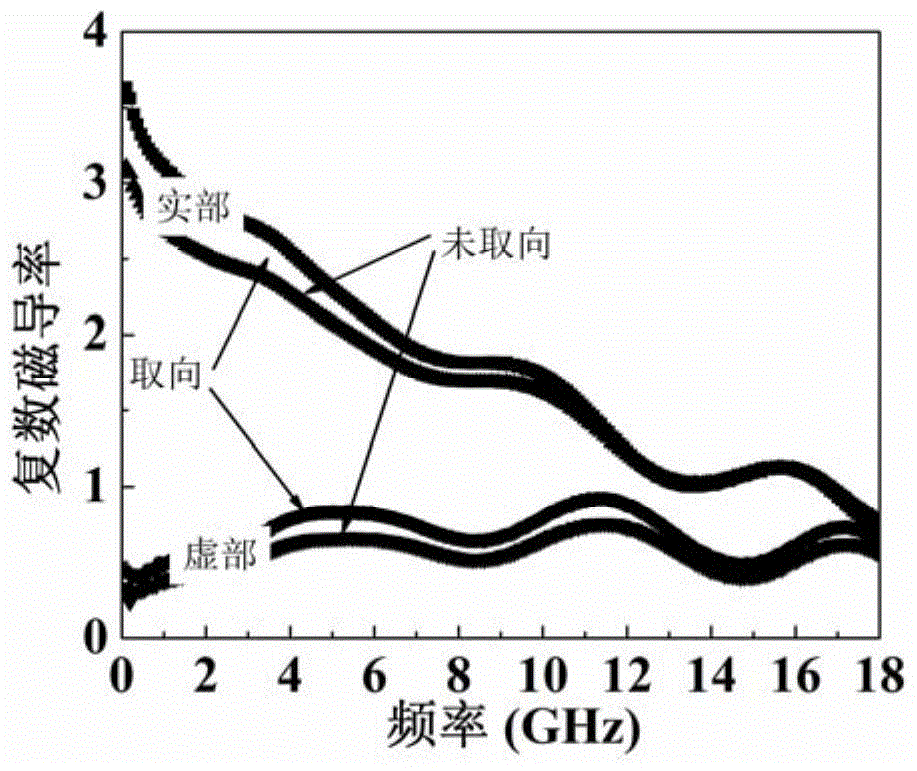

[0041] The dual-phase nanocrystalline high-frequency soft magnetic material of embodiment 1 is made of nanometer-sized ThMn 12 Rare earth intermetallic compound Nd(Fe 0.7 co 0.3 ) 10 V 2 and 3d metal alloy Fe 0.7 co 0.3 Composite composition, configure R(Fe x co 1-x ) a m 12-a : A is 50:50 (volume ratio).

[0042] The preparation method of the dual-phase nanocrystalline high-frequency soft magnetic material of embodiment 1 comprises the following steps:

[0043] a) Weigh 8.6980g Nd, 24.6957g Fe, 11.1692g Co and 5.8512g V, Nd(Fe 0.7 co 0.3 ) 10 V 2 with Fe 0.7 co 0.3 The volume ratio is 50:50, and it is smelted into a master alloy under the protection of argon;

[0044] b) A quenched alloy in an amorphous state, a nanocrystalline state or a mixed state of amorphous and nanocrystalline state is obtained by the melt rapid quenching method, and the rapid quenching line speed is 20 m / s;

[0045] c) Grind the prepared quick-quenching alloy into particles with a part...

Embodiment 2

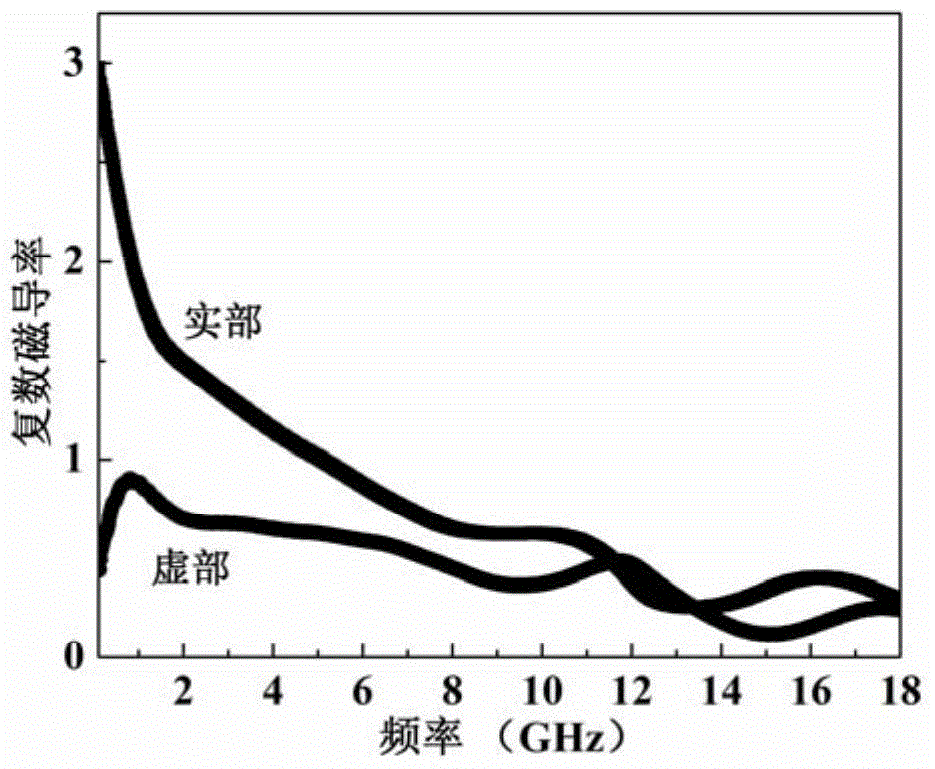

[0053] The dual-phase nanocrystalline high-frequency soft magnetic material of embodiment 2 is made of nanometer-sized ThMn 12 Rare earth intermetallic compound Nd(Fe 0.5 co 0.5 ) 10 V 2 and 3d metal alloy Fe 0.5 co 0.5 Composite composition, configure R(Fe x co 1-x ) a m 12-a : A is 5:95 (volume ratio).

[0054] The preparation method of the dual-phase nanocrystalline high-frequency soft magnetic material of embodiment 2 comprises the following steps:

[0055] a) Weigh 3.7751g Nd, 21.1932g Fe, 22.3652g Co and 2.6665g V, Nd(Fe 0.5 co 0.5 ) 10 V 2 with Fe 0.5 co 0.5 The volume ratio is 5:95, and it is smelted into a master alloy under the protection of argon;

[0056] b) A quenched alloy in an amorphous state, a nanocrystalline state, or a mixed state of an amorphous state and a nanocrystalline state is obtained by a melt rapid quenching method, and the rapid quenching line speed is 80 m / s;

[0057] c) Grind the prepared quick-quenching alloy into particles of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency | aaaaa | aaaaa |

| Resonant frequency | aaaaa | aaaaa |

| Resonant frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com