Temperature control dry heating prevention electronic cigarette and temperature control method thereof

An electronic cigarette, anti-dry burning technology, applied in the field of electronic cigarettes, can solve the problems of burning electronic cigarettes, harmful gas and burnt smell inhaling human body, harmful to human health, etc., to prevent dry burning, avoid burning or scalding the human body. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings:

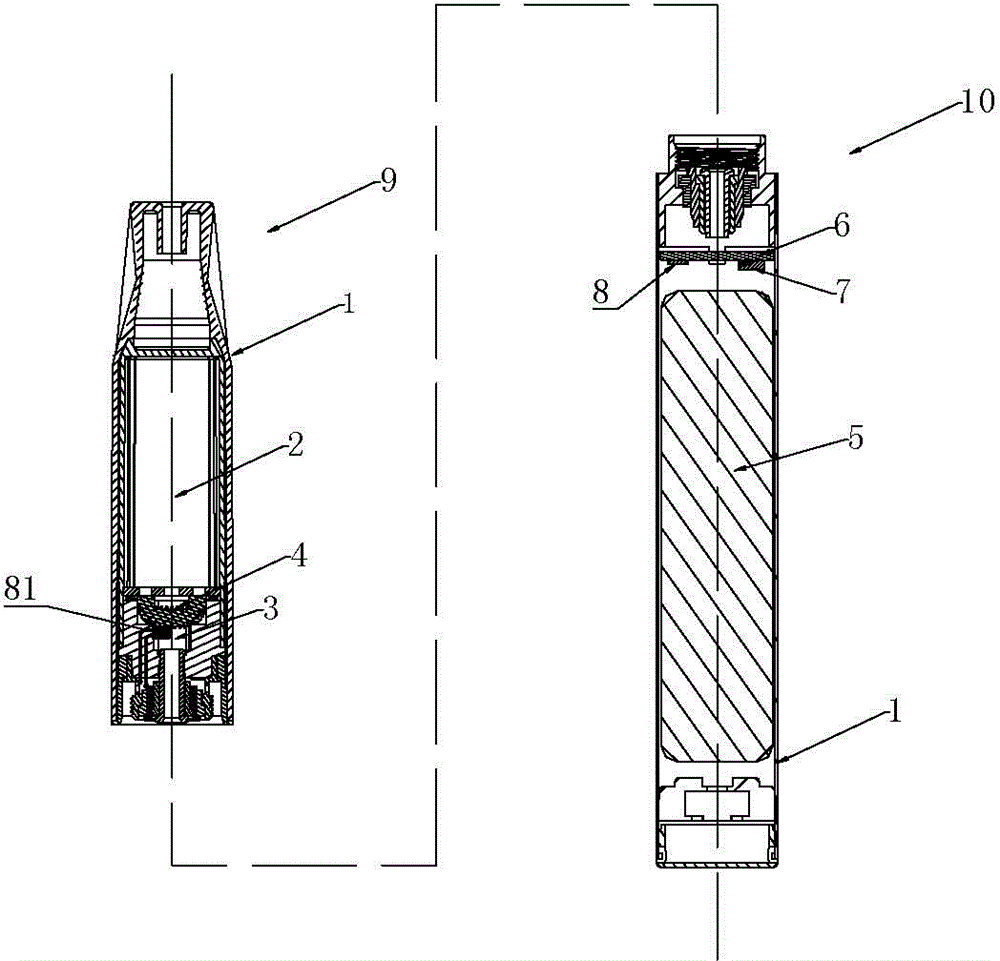

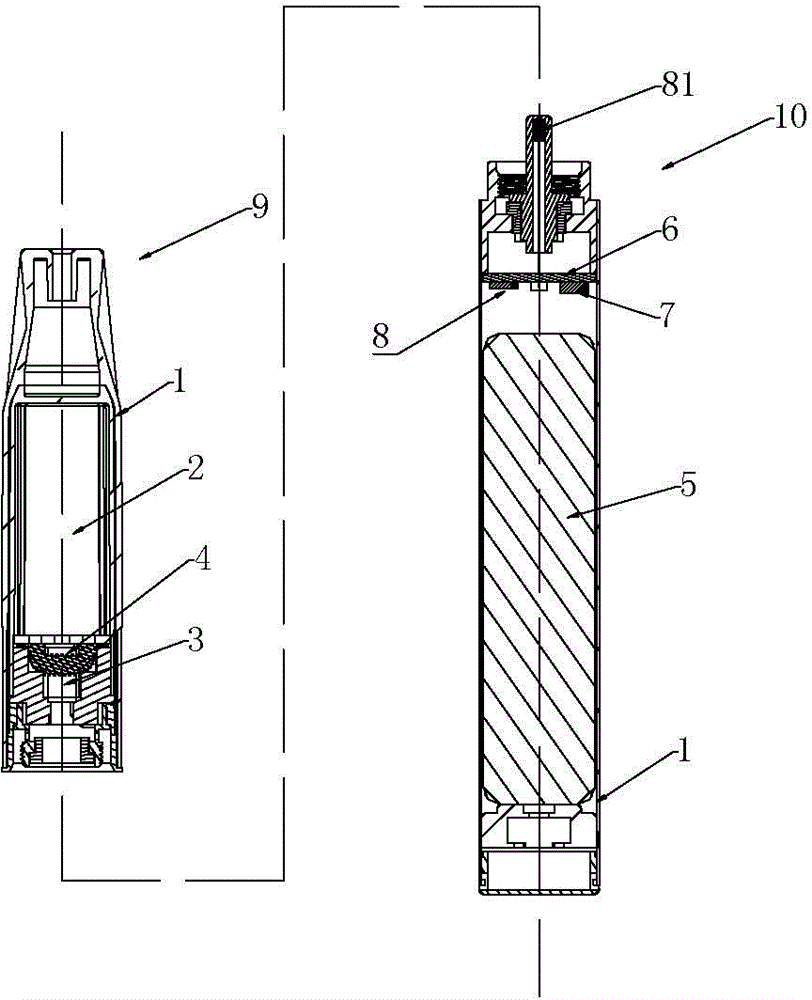

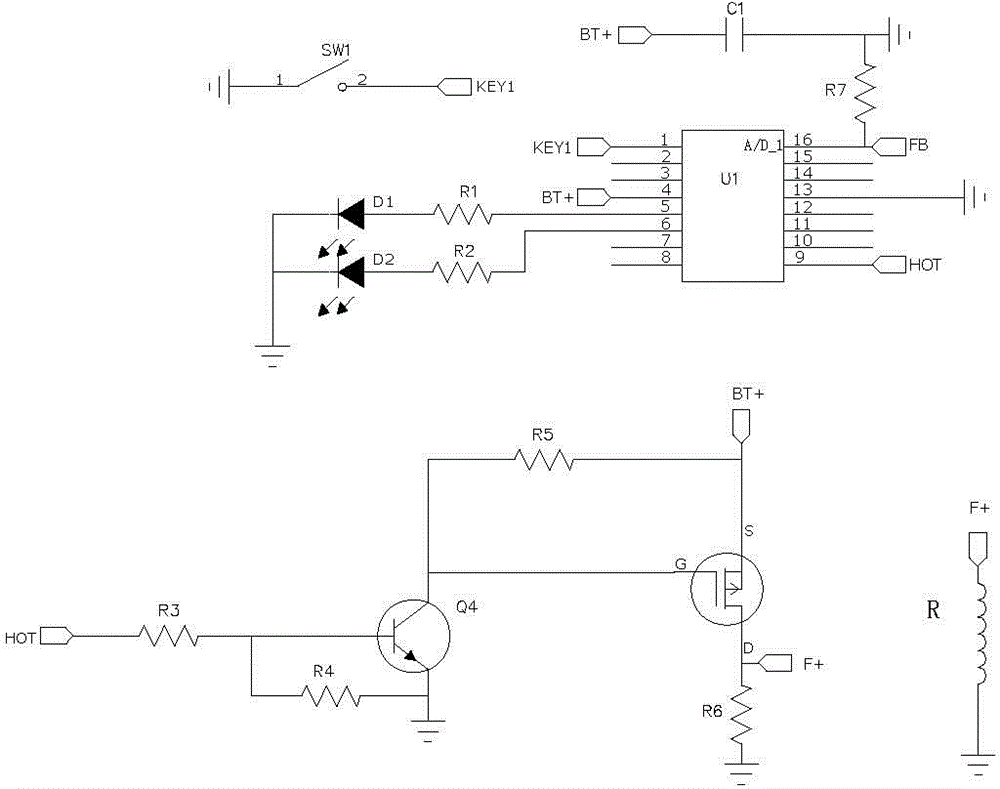

[0043] see figure 1 As shown in the figure, the temperature-controlled anti-dry-burning electronic cigarette according to the embodiment of the present invention includes a housing 1 and a liquid storage device 2 set in the housing 1, an atomizing component provided with an atomizing cavity 3 and a heating wire 4, and a power supply 5 And a circuit control board 6 with a smoking switch SW, the circuit control board 6 is provided with a power management module 7, a temperature sensing unit 8, and the temperature sensing unit 8 includes a temperature sensor 81 arranged in the atomizing chamber 3, and the temperature sensing unit 8. Induce the temperature signal in the atomizing chamber 3 and convert it into a temperature electrical signal and transmit it to the power management module 7. The power management module 7 generates a control electrical signal after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com