Magnetic isolation ring

A magnetic isolation ring and base material technology, which is applied in the fields of magnetic/electric field shielding, non-electric welding equipment, electrical components, etc., can solve the problems of easy melting of magnetic isolation rings, high product defect rate, and high cost, and achieve stable and reliable product quality. The effect of reducing material cost and product defect rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In conjunction with the accompanying drawings, the present invention is described in detail, but the scope of protection of the present invention is not limited to the following embodiments, that is, all simple equivalent changes and modifications made with the patent scope of the present invention and the content of the specification are still patents of the present invention. covered.

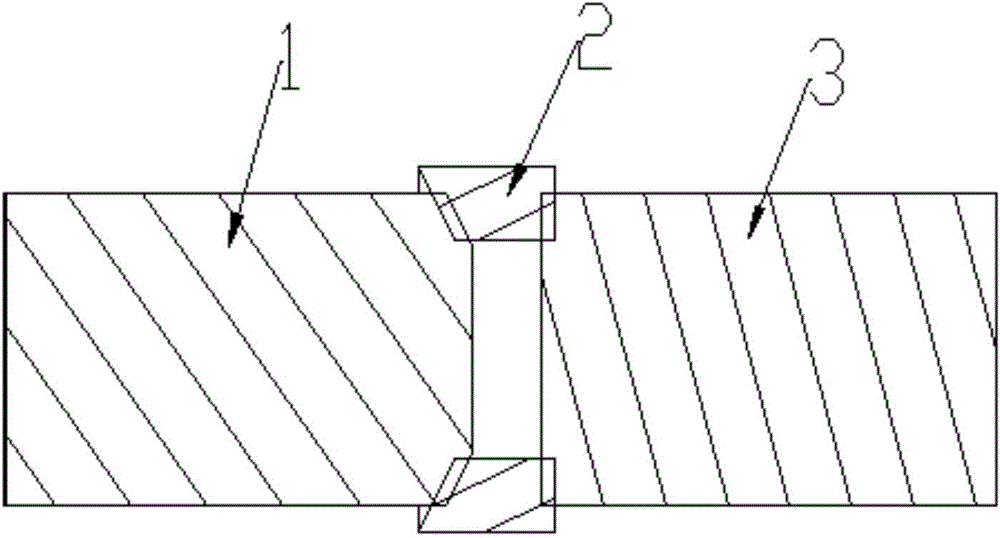

[0012] like figure 1 As shown, a magnetic isolation ring is formed by sequentially welding a first base material 1, a welding material 2 and a second base material 3, wherein both the first base material and the second base material are steel, and the welding material is stainless steel. Both the first base material and the welding material and the second base material and the welding material are connected by friction welding.

[0013] The magnetic isolation ring utilizes the principle of frictional heat generation to effectively combine the three sections of materials, which greatly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com